- The molds are installed on the high pressure die casting machine and then cleaned, preheated and lubricated to ensure smooth metal flow and prolong mold life.

- Heating the zinc alloy in the furnace of the hot chamber die casting machine and controlling the proper temperature.

- The die casting machine injects the melted zinc alloy into the mold cavity at high speed through the pressure injection head.

- Metal in the mold rapid cold indeed solidification.

- The mold opens and the ejector system pushes the casting out of the mold.

- The overflow is removed and, if necessary, sanded and deburred.

- If necessary, the casting may require further machining, surface treatment or coating.

Zinc Die Casting

Zinc die casting is a manufacturing process in which molten zinc (or zinc alloy) is injected into a die casting mold under extremely high pressure, and when solidified, a highly precise and accurate metal part is obtained.

Advantages of Zinc die casting:

- Good mobility, can make complex structure, can make very fine, complex, thin-walled small parts.

- High molding accuracy, casting surface smooth, less post-processing.

- Zinc alloy has high strength, good toughness, and at the same time there is a certain degree of elasticity, can resist impact, not easy to break.

- Strong corrosion resistance, not easy to rust.

- Moderate cost, fast processing speed, cost-effective.

_1751360230_WNo_1000d700.jpg)

Zinc Pressure Die Casting in Innovaw

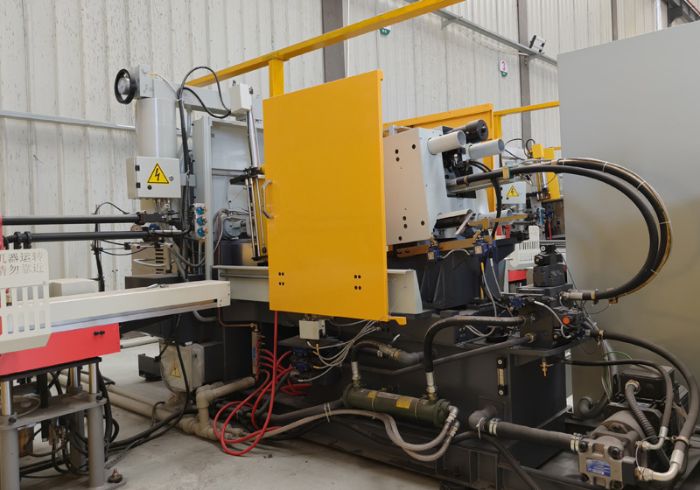

Our zinc die casting production line is produced in parallel with aluminum die casting, of which the main force is 5 hot chamber high pressure die casting machines with a main tonnage of 280 tons. We can undertake zinc alloy parts with sizes ranging from a few millimeters to more than a hundred millimeters and weights ranging from a few grams to 1,000 grams. Zinc alloy castings are mainly used in automobile, electronic and electrical appliances, home building materials, hardware, toys and other industries.

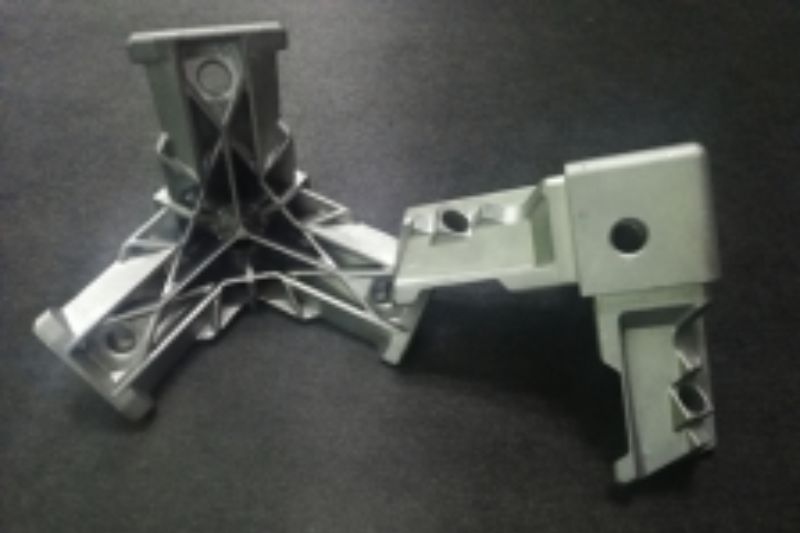

Products Cases on Zinc Pressure Die Casting

Material Scope

Our foundry possesses casting capabilities for materials including aluminum, magnesium, and zinc, with all materials meeting major international standards such as ASTM, JIS, DIN, ENAC, ISO, and GB. Commonly used materials are as follows:

- Aluminum

ASTM-A413, A360, A380, A383

JIS-ADC1, ADC3, ADC10, ADC12

DIN-AlSi12, AlSi10Mg, AlSi8Cu3

AlSi11Cu3, AlS110MnMg, AlSi10Mn, AlSi9Cu3, AlSi11Cu2

ENAC-44100, 43400, 46000, 46400, 43500, 46500

KAlloy

- Zinc

ZnAl4, ZnAl4Cu0.4, ZnAl4Cu1

ZnAl4Cu3, #2, #3, #5, #7

- Magnesium

AZ91D, AM60B

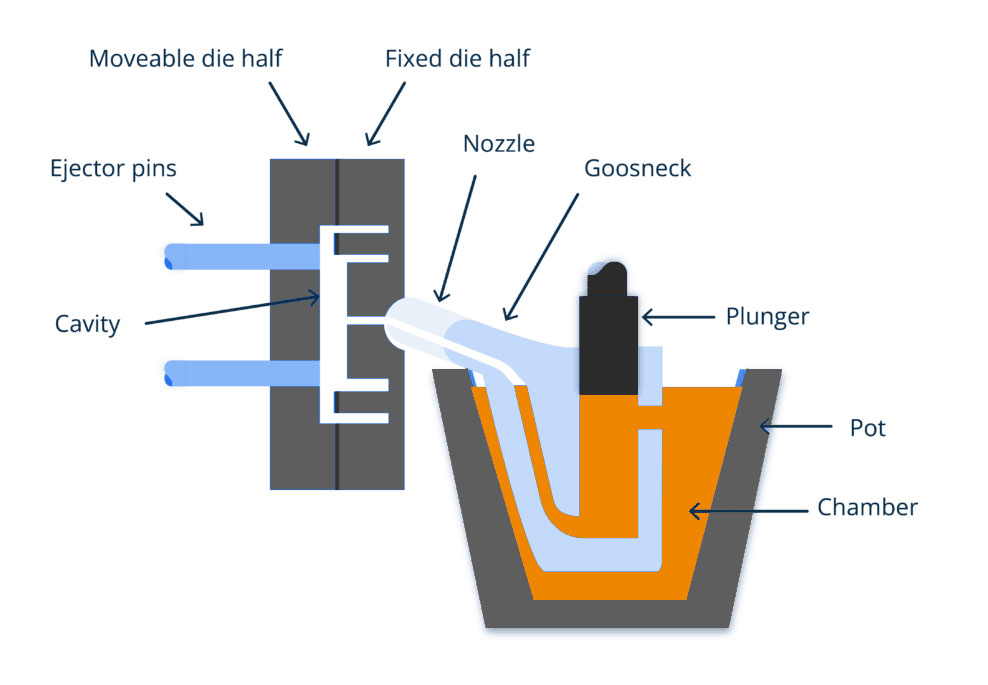

How Zinc Pressure Die Casting Works

Zinc high pressure die casting is a manufacturing process used to produce zinc alloy metal parts, produced by using a high pressure die casting machine to inject molten zinc into the die casting mold to obtain parts with high precision, excellent surface finish and tight tolerances. After receiving customer drawings, Innovaw engineers conduct DFM analysis to design and manufacture corresponding zinc high-pressure die casting molds. The process then proceeds to die casting production, with the specific workflow as follows:

Zinc Pressure Die Casting FAQs

Q1. Zinc die casting can only use high pressure die casting process?

Zinc die casting may not necessarily only adopt high-pressure die casting process, but high-pressure die casting is the most suitable die casting method for zinc alloy, which is decided by the characteristics of zinc alloy. The melting point of zinc alloy is low, suitable for rapid injection into the mold. Zinc alloy has good fluidity, can fill complex mold structure. The solidification speed of zinc alloy is fast, which is suitable for efficient mass production. Because of these characteristics of zinc alloy, not very suitable for other casting form, such as gravity casting, zinc alloy liquidity although good, but gravity casting cooling slow, low efficiency, not economic. In summary, high pressure die casting is the best choice for zinc alloy die casting, almost monopolize the zinc die casting market.

Q2. Why is zinc die casting suitable for hot chamber die casting machine instead of cold chamber die casting machine?

Because the physical properties of zinc alloys and the structural characteristics of hot chamber die casting machines are highly compatible, zinc die casting is suitable for the use of hot chamber die casting machines, while cold chamber die casting machines are usually not used. Zinc alloys have a low melting point, lower than aluminum, and are suitable for hot chamber structures. Zinc alloy has low corrosiveness to steel and will not damage the hot chamber die casting machine's ejection mechanism, so it has a long service life and stable operation. Zinc alloy has very good fluidity and is suitable for efficient and fast injection in hot chamber die casting machine. Zinc die casting most of the small and medium size, complex structure, high precision requirement parts, chamber die casting machine just good at this kind of products of high precision, high repeatability production. And if the cold chamber die casting zinc alloy, not only low efficiency, high cost, and equipment does not match the flow characteristics of zinc alloy.

Q3. What are the advantages and disadvantages of zinc die casting compared to aluminum die casting in terms of performance?

Zinc die castings and aluminum die castings are both common metal forming products, they have their own advantages and disadvantages in terms of performance, applicable scene, cost and processing characteristics. Compared to aluminum, zinc die castings have the advantages of higher dimensional accuracy, smaller tolerances, better fluidity, good surface quality, excellent toughness and impact resistance, and long die life. However, the disadvantages of zinc die castings are also obvious for aluminum, mainly the disadvantages of heavier weight, poor high temperature performance, poor corrosion resistance and a slightly higher unit cost of material.

Q4. Is zinc die casting delivery fast?

Yes, zinc die casting delivery is usually faster. Zinc die castings take only 2-5 seconds per die casting, which is faster than aluminum die casting and is better suited for quick delivery of large quantities. Zinc die castings have a long mold life and less frequent mold changes, which reduces production downtime. There are other characteristics such as short cooling time, fast solidification speed, easy automation, less post-processing and so on. In summary, zinc die casting is the fastest casting method, is also one of the important reasons why it is widely used.