Product Description

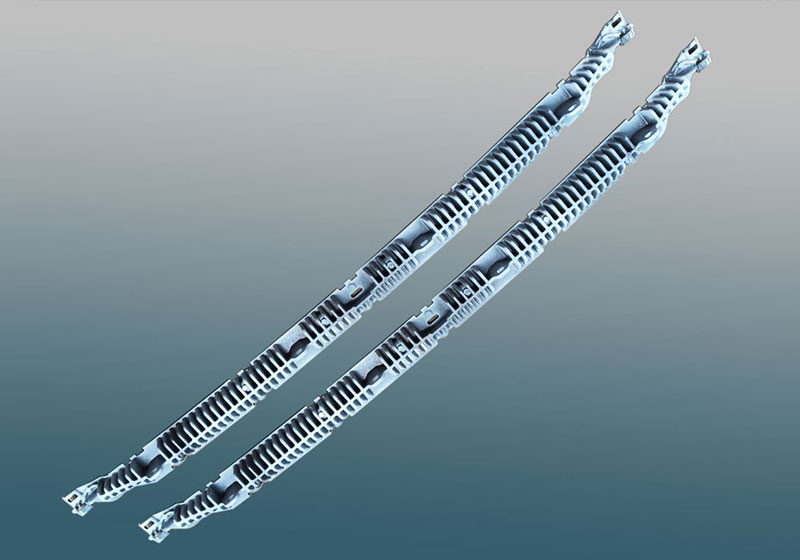

This is a customized water heater parts aluminum casting, the material is aluminum alloy, presumably for the water heater circulating pump connection housing. As the core component of the water heater system. Its main role is:

1. as a connection between the main water heater tank, heating pipes, circulation pump and other components, to guide the water flow in the water heater internal circulation.

2. as a structural support, to maintain the sealing and stability of the piping system.

3. as installation connection interface, connecting different accessories.

This water heater circulating pump connection housing aluminum casting finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection characteristics, but also easy to install and maintain. The finished product fully meets the customer's design objectives, providing a higher performance and more reliable solution for the design of such water heater components.

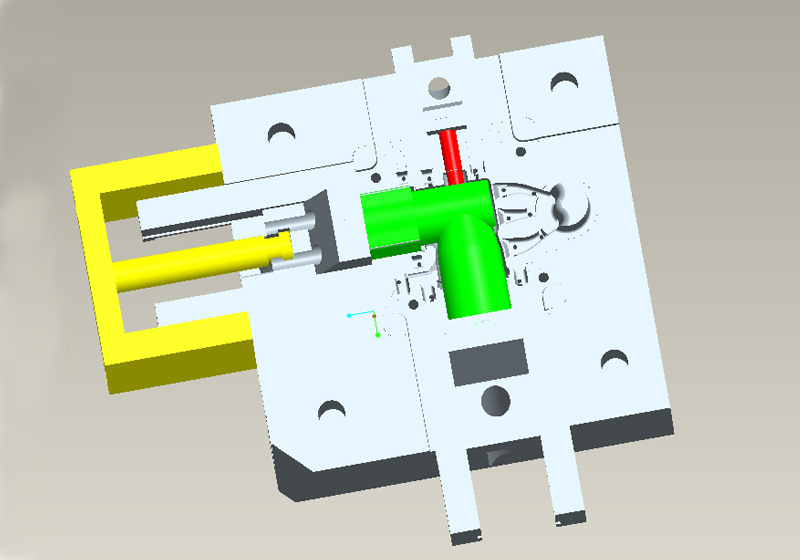

This water heater connection housingl aluminum casting adopts aluminum high-pressure die casting one-piece molding plus CNC machining process, surface oxidation treatment, compared with other aluminum casting process, it has the characteristics of high precision, small tolerance, small wall thickness, high production efficiency, low material loss, light weight but high strength, which is a perfect fit for the mass production needs of this shell cover.

Customized aluminum high pressure die casting, not only in this water heater circulating pump connection housing aluminum casting to get a good application embodiment, but also in other automotive industry, industrial automation control equipment, electric motors, instrumentation and other products can be widely used. No matter what kind of specification or design, you can get a good match for the application.

Production Process

Mould making→Pressure Die Casting→Cutting the sprue and riser→Grinding→CNC Machining→Anodizing→Packaging & inspection

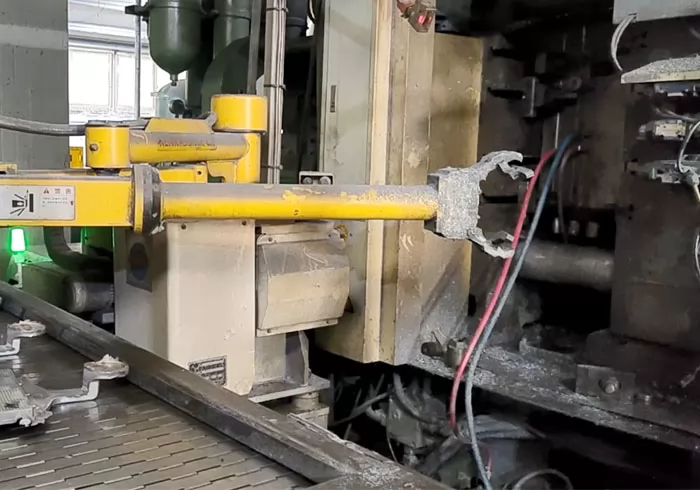

Production Show

Product story

As a result of Innovaw's consistently high standard of service, this purchaser of water heater parts has been so satisfied with Innovaw's technology and quality control that it has entrusted us with the production of several lines of water heater parts for many years.

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.

Share your thoughts

Showing

6

of

0

reviews