VDA6.3 & VDA6.5

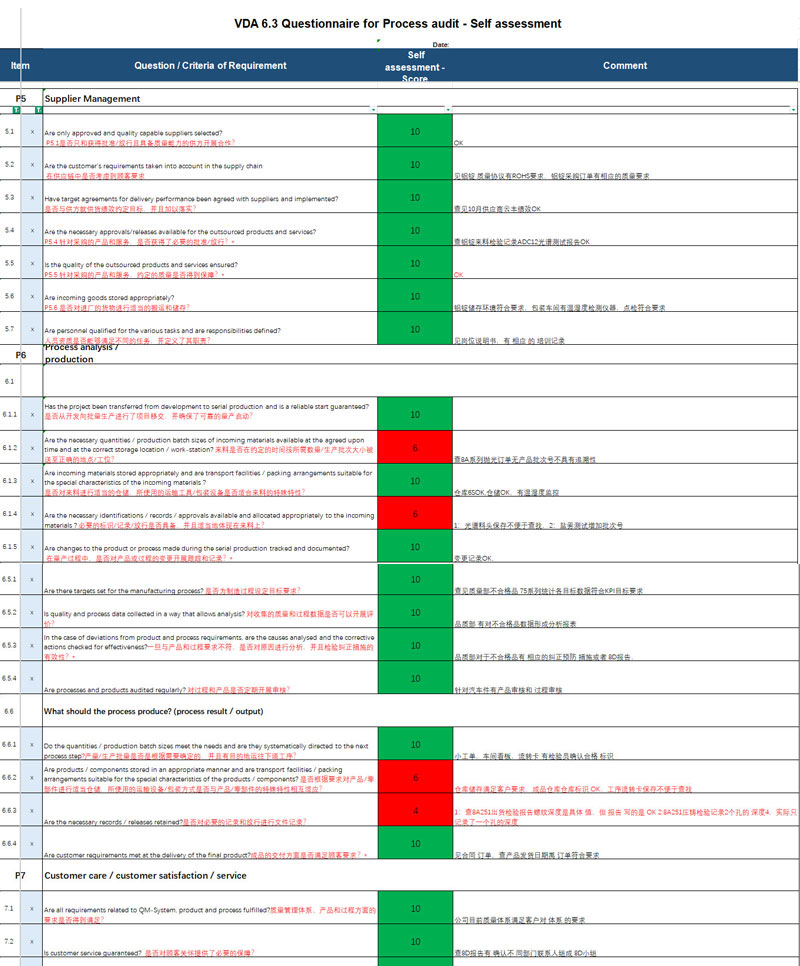

VDA6.3 is a process audit standard published by the German Association of the Automotive Industry (VDA), primarily used to evaluate and enhance a company's quality management capabilities during product realization. It covers aspects such as project management, product development, process development, mass production, and service delivery.

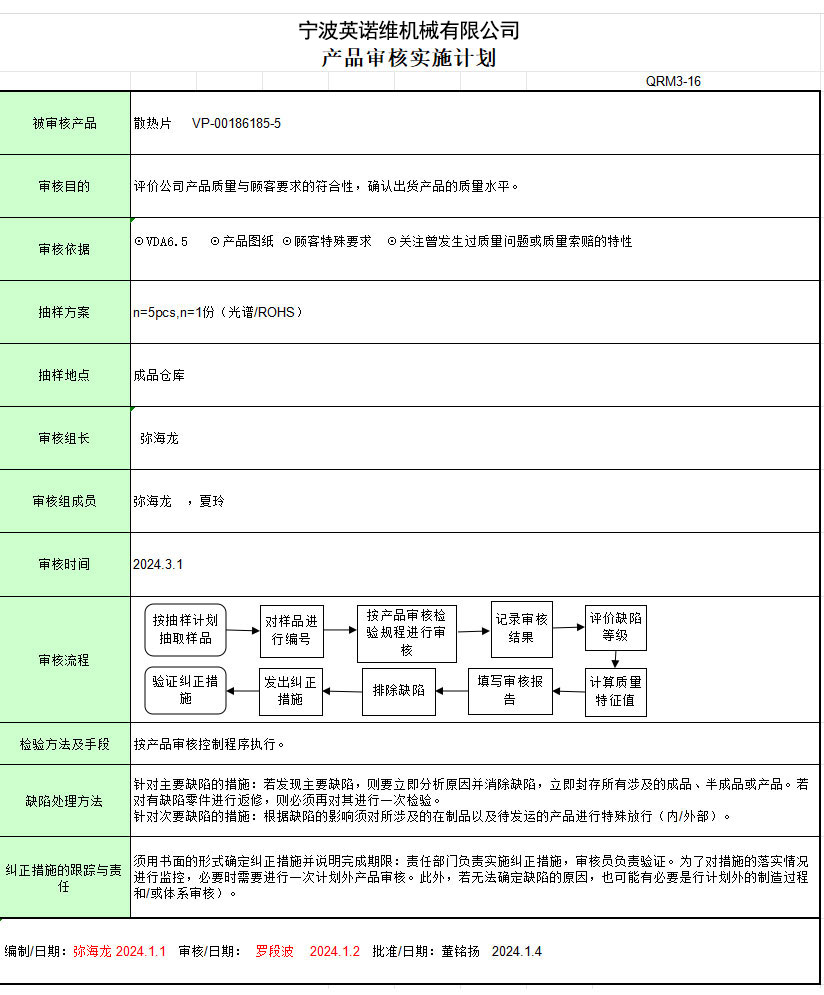

VDA6.5, on the other hand, is a product audit standard. It involves sampling and evaluating physical products to verify compliance with design specifications and customer requirements.

Primary Applications and Functions:

VDA 6.3 is primarily applied in supply chain management, process evaluation, and supplier audits. It helps identify process weaknesses, drives process improvements, and enhances production consistency and reliability.

VDA 6.5 is mainly used for finished product quality control and product consistency verification. It enables companies to inspect final product quality from the customer's perspective.

Combined, these standards ensure both process stability and control while guaranteeing product compliance with customer requirements, holding significant importance in the automotive industry and other high-quality manufacturing sectors.

As a company that manufactures metal components for global clients, we integrate VDA6.3 and VDA6.5 audit methodologies into our quality management system:

Through VDA6.3 audits, we systematically evaluate production processes to ensure controllability, continuous optimization, and reduced quality risks.

Through VDA6.5 product audits, we conduct sampling verification of finished goods to confirm compliance with standards and expectations from the customer's perspective.

This dual assurance mechanism enables us not only to guarantee manufacturing efficiency and stability but also to ensure that delivered products meet or exceed customer quality requirements. This approach continuously enhances customer satisfaction and strengthens our competitive edge.

Sample Quality Documents

VDA 6.3 Questionnaire for Process audit - Self assessment