Product Description

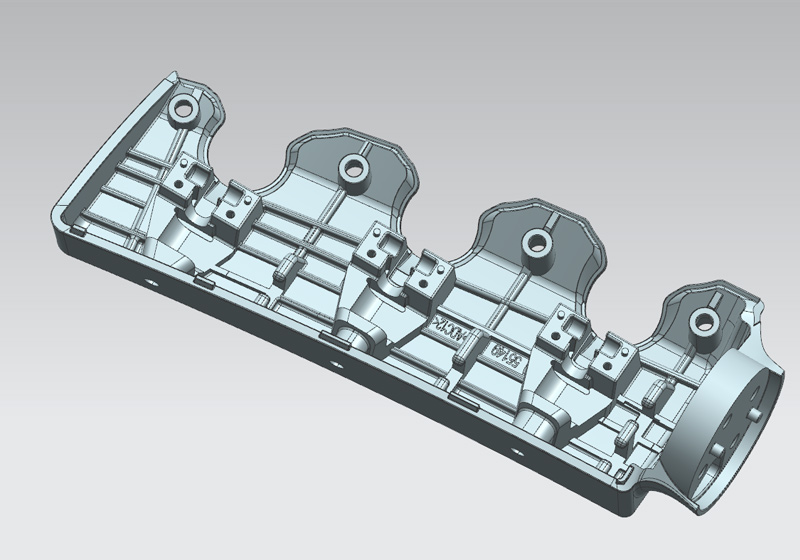

This is a customer to customize dental chair armrest aluminum casting, is an important part of the dental chair, using ADC12 material. Its main role is:

1. as an important structural support member, bearing weight, keeping the chair stable, connecting various parts of the structure.

2. It may also be a functional component bracket to ensure precise positioning and flexible adjustment of medical equipment during procedures.

3. ergonomic aids

Aluminum casting parts are used in dental chairs, which have the advantages of light weight, moderate strength, good corrosion resistance, good thermal conductivity, etc., which are suitable for the environmental use requirements of dental chairs. The finished product fully meets the customer's design objectives, providing a higher performance and more reliable solution for this type of medical equipment design.

The aluminum casting of this dental chair adopts aluminum high-pressure die-casting one-piece molding plus cnc machining process, and the final surface treatment is powder coating. Compared with other aluminum casting process, it has the characteristics of high precision, small tolerance, small wall thickness, high production efficiency, low material loss, light weight but high strength, which perfectly fits the mass production demand of this dental chair parts.

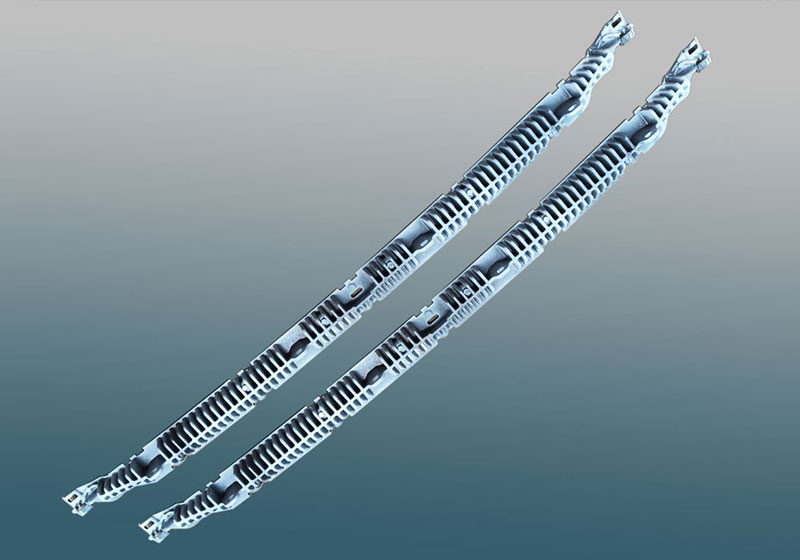

Customized aluminum high-pressure die castings are not only well reflected in this dental chair, but also can be widely used in medical devices, industrial automation control equipment, electric motors, instrumentation and other products. No matter what kind of specification or design, it can get a good matching application.

Production Process

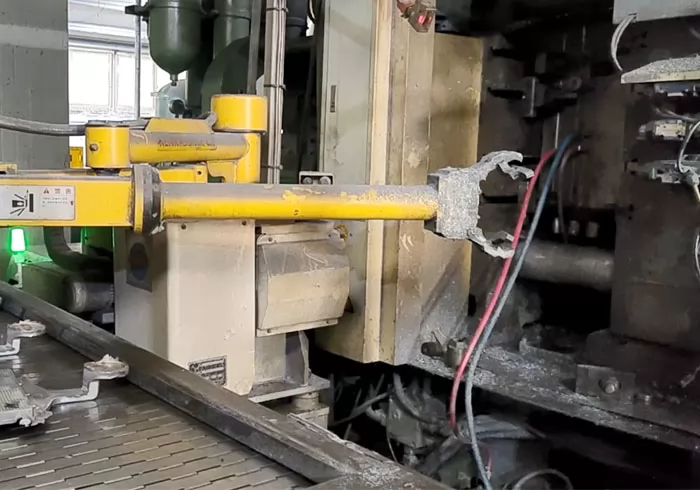

Mould making→Pressure Die Casting→Cutting the sprue and riser→Grinding→CNC Machining→Powder Coating→Packaging & inspection

Production Show

Product story

This is an old customer in the medical industry, who has placed orders for a variety of aluminum castings for medical parts with our company one after another over the past few years. Our smooth quality control and timely delivery performance are highly praised by the customer. This time, the newly developed dental chair contains a variety of aluminum alloy fittings in different positions, and the customer has delivered them all together to our company for production. Basically, we keep the frequency of shipment once a month.

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.

Share your thoughts

Showing

6

of

0

reviews