Ship Lighting Work Light Development Case

Project Brief

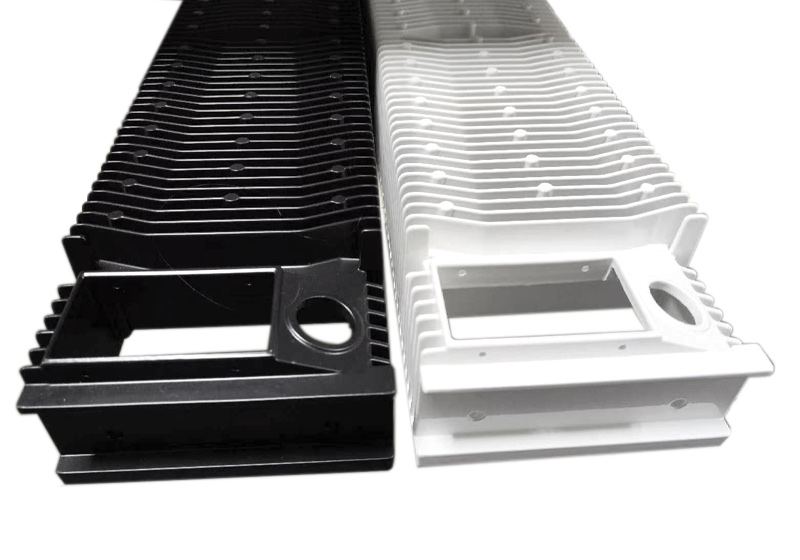

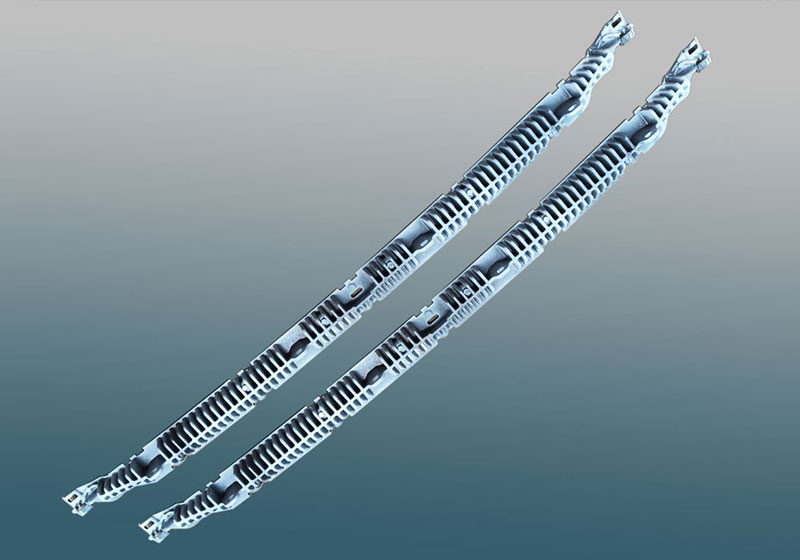

This is a custom-designed special LED work light housing for ship lighting components. It not only protects the internal LED components but also serves multiple functions including thermal management and mechanical support.

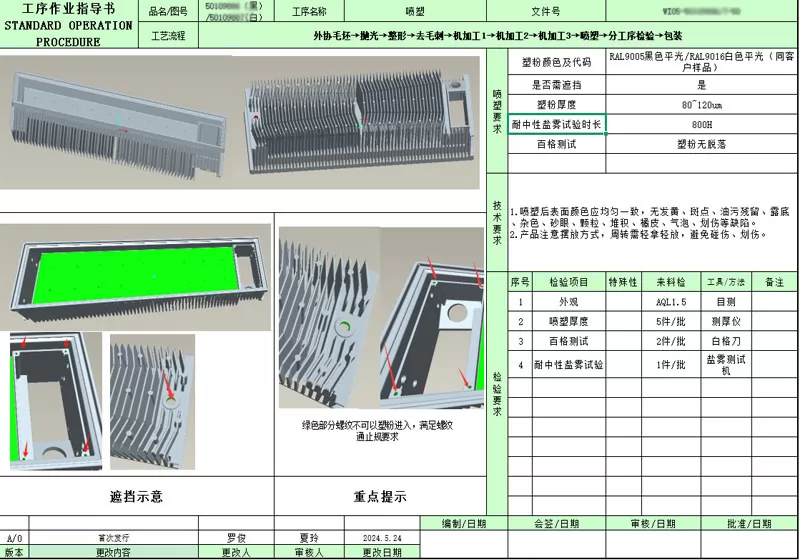

1. Product Standards & Requirements: Material: K-ALLoy; General dimensional tolerance grade: ISO 2768-mK; Minimum flatness: 0.3; Perpendicularity: 0.2; Concentricity: 0.3; Flawless appearance (no visible defects); Surface roughness: Ra6.3µm; Surface coating thickness: 80~120µm; Neutral salt spray test duration: 800 hours. PPAP approval must be completed and passed before formal mass production.

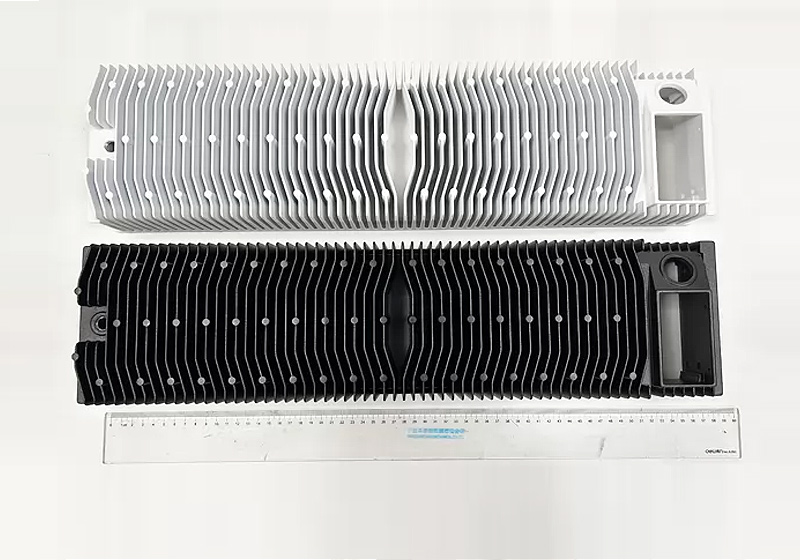

2. Product Challenges: The K-ALLoy material has poor fluidity. Combined with the product's large size (length 566mm, weight 4.5KG), dense fins, and significant depth, die casting is particularly difficult. Furthermore, this size and weight make the product prone to deformation. Inclined holes are susceptible to misalignment, and flash tends to be thick.

Risk Keywords: Complex structure, Poor fluidity, Short shot, High precision, Porosity, Assembly accuracy, Prone to misalignment.

The finished product must possess excellent machining precision and surface finish, along with good thermal conductivity, corrosion resistance, and lightweight characteristics, while also being easy to install and maintain. The overall project is challenging, particularly testing our capabilities in mold design, quality control, and delivery.

Development Process

Following the core methodology of the internationally advanced IATF 16949 standard - Advanced Product Quality Planning (APQP), we formed a project development team comprising mold designers, casting engineers, machining engineers, measurement engineers, quality engineers, and sales. Focusing on quality, we entered the comprehensive product development process.

The first step involved DFM analysis to thoroughly understand and optimize certain product details for enhanced manufacturability, establishing mutually agreed-upon technical specifications and quality standards with the customer.

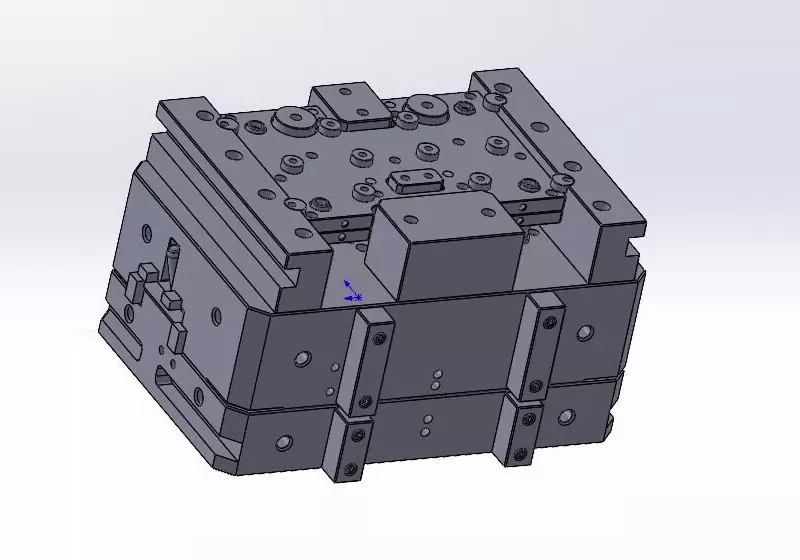

Considering the application environment and performance requirements of this ship work light housing, the customer specified the material as K-ALLoy alloy. Based on the material properties and the core design elements of the product, the process route of high-pressure die casting (HPDC) + CNC precision machining was ultimately determined, balancing technical feasibility, quality stability, and cost control. An 800T high-pressure die casting machine was selected with a 1-cavity mold.

Subsequently, technical engineers performed mold simulation and mold flow analysis to predict and optimize various challenges and process parameters, and established preliminary Process Flow Charts and Control Plans.

Finally, the plan was gradually validated, and issues were identified and resolved in the subsequent practical stages.

Practice Validation & Optimization

For the development of this ship work light housing casting project, our company adopted an approach of first designing the overall process flow, then progressively validating it step by step according to this flow. Starting from mold manufacturing, the project entered the actual production phase. Our company proceeded according to the initial Process Flow Chart, applied FMEA tools for risk analysis and assessment of various potential failure modes, and utilized Statistical Process Control (SPC) for core parameter data analysis, enabling continuous monitoring and improvement. The main key issues encountered during the actual manufacturing process were as follows:

A. Solving HPDC Challenges with K-ALLoy for This Project

K-Alloy is a high-corrosion-resistant aluminum alloy specifically designed for die-casting applications, often used in harsh environments like marine settings. However, this comes at the cost of some fluidity, leading to issues like short shots, cold shuts, and insufficient filling in thin-walled, complex structures. Particularly for this project, which features numerous fine, deep heat dissipation fins, using K-Alloy presented significant difficulty. During the trial mold phase, quality engineers identified localized short shots. The technical team conducted multiple reviews and established the following optimization strategies:

1. Repeated mold flow analysis to optimize gate location and runner design, determining the optimal configuration.

2. Increasing core parameters such as mold temperature and injection speed.

3. Modifying the mold venting design.

The implementation of these strategies proved effective across multiple batches, successfully avoiding defects in the K-Alloy die-casting blanks and allowing progression to the next process stages.

B. Calibration Fixture Solves Deformation Challenge

This ship work light heat sink aluminum casting is characterized by its long shape, heavy weight, thick sections, and dense fins prone to shrinkage. Consequently, it is difficult to avoid slight deformation after the die-casting blank is ejected. Engineers measured sample deformations typically ranging from 0.8~1.5mm, up to a maximum of 3mm. Addressing this issue, our technical team leveraged prior similar experience to specially manufacture a calibration mold fixture. After calibration, the flatness of the product reached 0.5mm, effectively resolving the deformation problem.

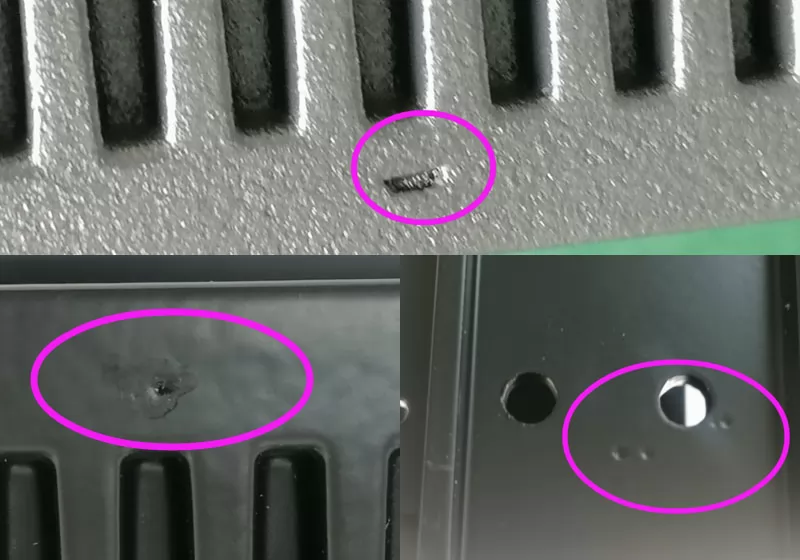

C. Machining Addresses Inclined Hole Misalignment and Flash Issues

During actual sampling, misalignment and excessive flash were found on the inclined holes of the heat sink housing. Inspection revealed the cause: the mold for these holes is split between the upper and lower halves, making precise alignment during mold closing difficult, leading to misalignment. Various solutions were possible for this situation. Ultimately, based on economic rationale, this issue was delegated to subsequent CNC machining for resolution.

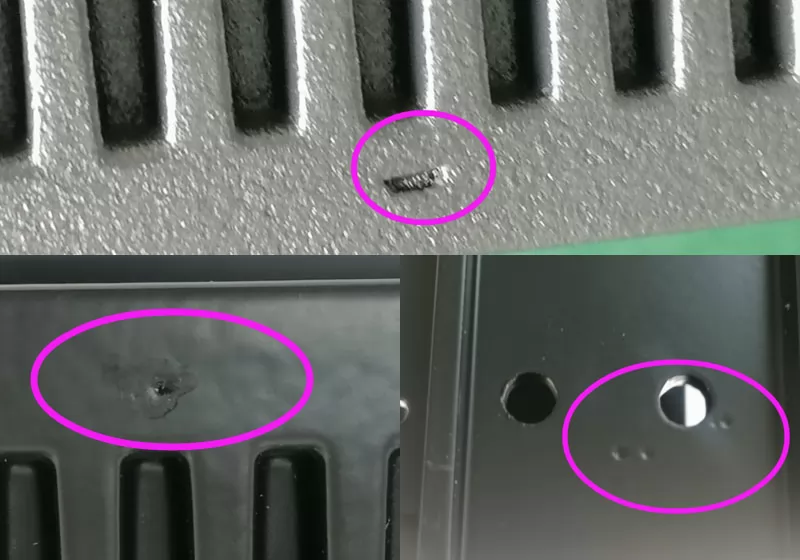

D. Strictly Executing the 800-Hour Salt Spray Test

Due to the marine application scenario of the ship work light heat sink, the customer has strict requirements for corrosion resistance. Beyond the inherent corrosion resistance of the K-Alloy material, the external surface also undergoes Powder Coating. We strictly executed the required neutral salt spray test exceeding 800 hours, verifying that the product complies with the technical specifications.

Quality Control

The entire development process was a systematic procedure of identifying and controlling quality risks while continuously optimizing the process. The ship work light heat sink project team leveraged rich experience and solid technology to conduct technical reviews and repeated verification at every process step, systematically identifying and tackling potential risk points. The team strictly adhered to the IATF 16949 quality system, implementing the full APQP process requirements to achieve full-process quality control. Throughout the process, various standardized documents and practices such as FMEA, SPC, MSA, and Control Plans were established and executed to prevent potential process risks, quality risks, and control quality variation. Finally, PPAP documentation was established and approved by the customer, laying a solid foundation for formal mass production.

The process included first-article inspection, in-process inspection, and outgoing inspection, establishing complete inspection data retention to ensure all quality data is traceable and verifiable.

Results and Evaluation

Finished Product Metrics:

1. Dimensional Accuracy: Including position and flatness, over 60 dimensional standards, all met.

2. Appearance: No visible defects, standard met.

3. Neutral Salt Spray Test: 800 hours, standard met.

4. PPAP completed and approved by the customer.

The development of this aluminum die-cast ship work light heat sink project by Innovaw, characterized by its high technical difficulty and stringent comprehensive performance requirements, served as a significant test of the manufacturer's overall capabilities. Relying on our profound expertise in high-pressure die casting, precision CNC machining capabilities, and an excellent quality management system consistently implemented throughout the process, we successfully overcame various challenges and delivered a high-quality product on time that met and even exceeded customer expectations. This project fully demonstrates our casting development team's professional capability for systematic problem analysis and efficient closed-loop improvement in developing complex structural components.

Production Process

Mould making→Melting→High Pressure Die Casting→Cutting the sprue and riser→Polishing→Straightening→Deburring→CNC Machining 1→CNC Machining 2→CNC Machining 3→Powder Coating→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.