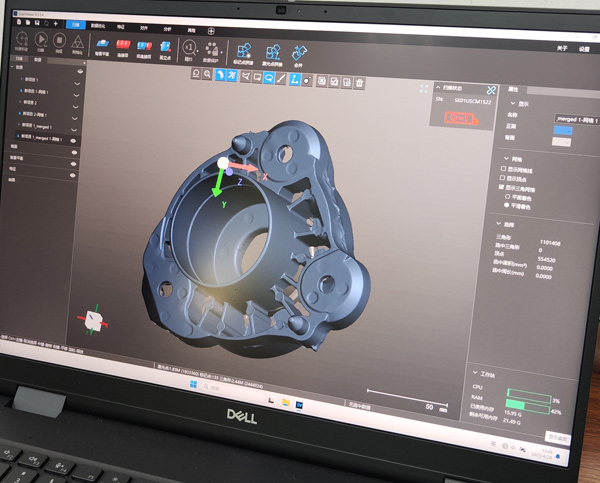

- 3D design using CAD, the model is saved in file formats such as “.STL” or “.OBJ”, which describe the geometry of the object.

- The CAD file is imported into a professional slicing program that generates machine instructions for the printer.

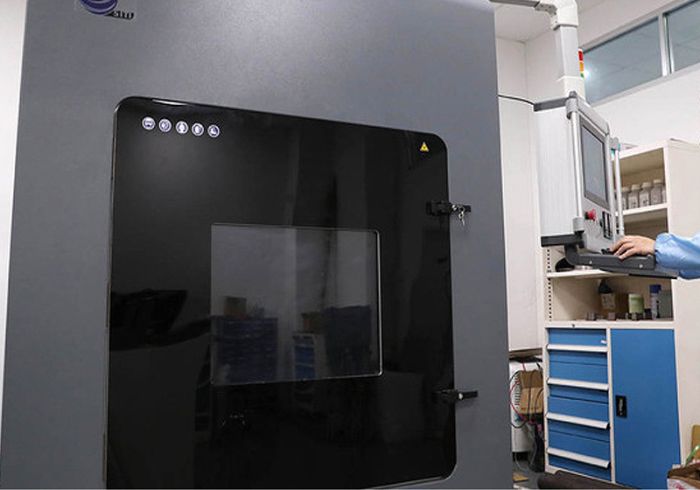

- Slice the model is fed into the rapid prototyping machine, which builds the model layer by layer.

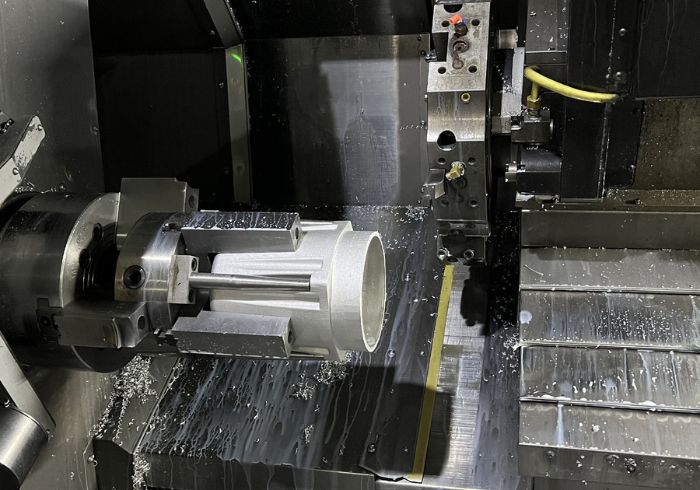

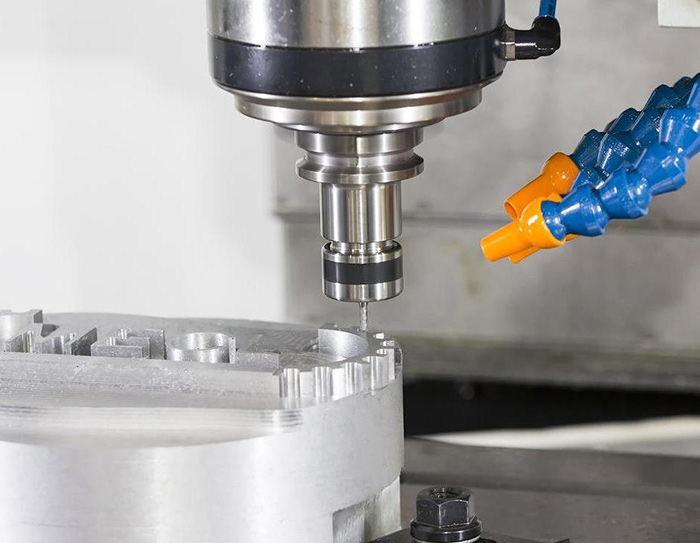

- After printing, necessary post-processing is performed, such as cleaning, curing, sanding and machining.

- Testing and validation is performed, including size, function, assembly, and so on.

Rapid Prototype Manufacture

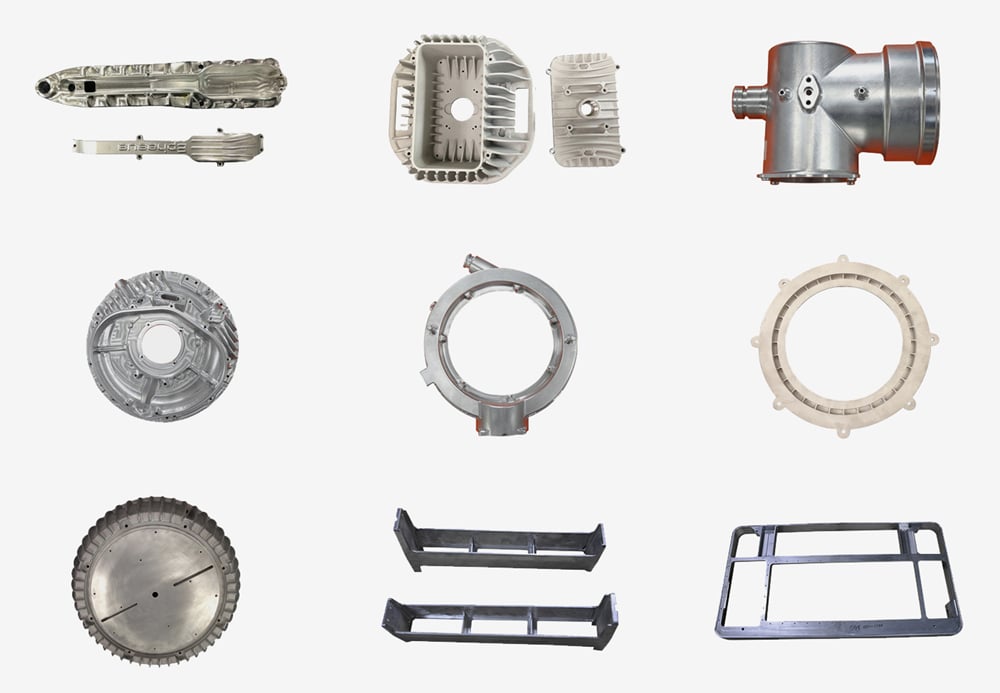

Rapid prototype manufacture is a technology used to quickly create product models or design verification parts, using digital models, through 3D printing or other automated means, to create a physical prototype of the product in a short period of time. In the foundry industry, rapid prototyping technology is gradually becoming an important part of digital casting and intelligent manufacturing. It has not only changed the production of traditional sand, wood or metal molds, but also significantly shortened the casting development cycle, reduced costs, and improved the success rate of trial production.

Advantages of Rapid prototype manufacture:

Shorten product development cycle: rapid prototyping in 1~3 days.

Rapid manufacture of complex molds/cores: sand, wax, and foam molds with complex structures can be directly manufactured.

Enhance casting accuracy and quality: digital models directly drive molding equipment with low error and high consistency.

Save mold and trial production costs.

Support structural simulation and process validation: rapid validation of key designs such as sprue systems, riser layouts, etc.

Rapid Prototype Manufacture in Innovaw

At Innovaw, we offer our customers the best rapid prototyping services with our advanced rapid prototyping technology and high-speed machining capabilities. We focus on prototyping through CNC prototyping, 3D printing, and other prototyping tools.

Get your design into production with our rapid prototyping service:

Proving the feasibility of your concept;

Allowing you to test mechanical variables;

Reducing development risk due to unclear software requirements;

Provide dimensional reports, material reports, PPAP Level 3 documentation reports, 8D reports, and corrective and preventive action reports;

Rapid Prototype Manufacture Cases

How Rapid Prototype Manufacture Works

Rapid prototyping is the rapid creation of physical models of a part or product design using computer-aided design data. These models are used for design validation, testing and iterative improvement before full-scale production begins. After receiving the customer's flat drawings, Innovaw's engineers use professional software to build 3D models and ultimately quickly manufacture finished prototypes.