INNOVAW QUALITY SYSTEM

As a company with the goal of sustainable development, Innovaw regards quality as the foundation for the survival and development of the enterprise. Our company implements Total Quality Management, which involves all staff from top management to frontline employees. We have established a corporate quality plan and determined that our quality objectives are to continuously improve the quality of our products and to pursue zero defects and 100% customer satisfaction.

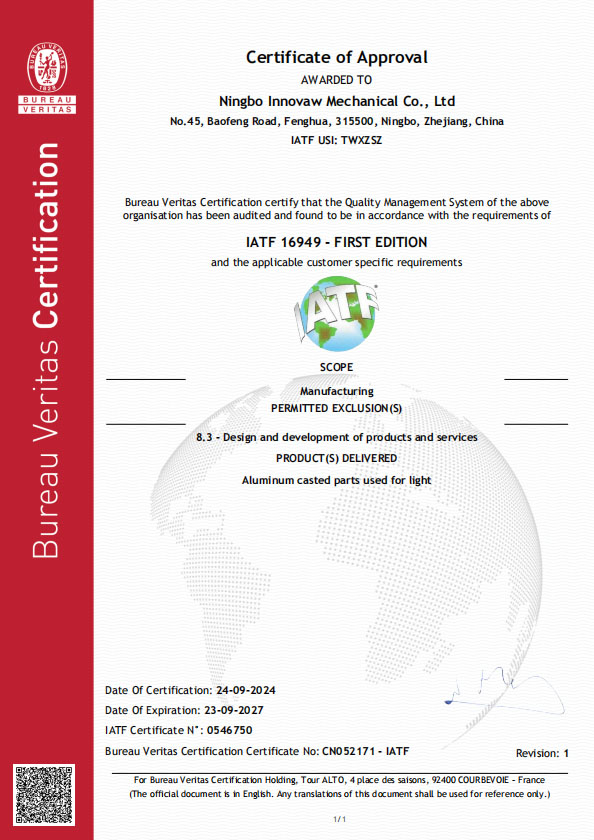

We implement the world-class IATF 16949 quality management system to guide and standardize our quality management activities. We establish a quality-centered Innovaw corporate culture through customer orientation, performance evaluation, data-driven, and process management. We establish quality management teams at different levels and quality management tools such as APQP, PPAP, SPC to realize quality control. We have established a whole-process product quality inspection system to realize quality assurance and promote continuous quality improvement. We have greatly improved our operational efficiency and brand reputation through total quality management.

Our Quality Management System

IATF 16949 is a quality management system standard developed specifically for the automotive industry, applicable to automotive manufacturers and their direct component suppliers. The requirements of IATF 16949 are higher than those of other quality management systems. The core requirements for companies are:

-

Customer Satisfaction and Continuous Improvement

-

Defect Prevention

-

Variation and Waste Reduction in Manufacturing Processes

-

Risk Management and Opportunity Identification

-

Supply Chain Management and Development

-

Product Safety and Compliance

-

Internal Audit and Corrective Action.

Quality Control System

Relying on the IATF 16949 quality system, combined with the characteristics of the metal casting industry, Innovaw has established a complete quality management system, which mainly includes the following subsystem modules:

1. Quality planning system

Including quality target setting, quality policy development, product quality planning (APQP), control plan development (Control Plan), process flow diagram and FMEA.

2. Quality control system

Including incoming material inspection, process inspection, finished product inspection, shipment inspection, testing standards and inspection procedures, first piece confirmation, sampling standards, etc.

3. Quality Assurance System

Includes system document management (manuals, procedures, work instructions), internal audits and management reviews, supplier quality management (SQM), customer complaint handling and preventive measures, calibration and measurement system management (MSA), production process audits (LPA, process audits).

4. Quality Improvement System

Corrective and Preventive Action, Continuous Improvement, Problem Solving (8D), Quality Cost Analysis

5. Equipment and Metrology Management System

Equipment maintenance and point inspection system (TPM), calibration of testing equipment (internal/external calibration), instrument asset management and effectiveness tracking

6. Personnel and Training Management System

Quality Awareness Training, Quality Skills and Testing Ability Training, Special Process Licensing System

What We Did

Realize the whole process of product quality inspection system

We have set up a corresponding quality management team for each product.

The quality management team apply APQP, FMEA, PPAP, MSA, SPC, including control plans and statistics analysis and other core tools to achieve production process control.

Innovaw apply regular process audit via VDA6.3 and product audit via VDA6.5

8D analysis and report is used regular for customer complaints to solve problems from the root.

Follow the world-class IATF 16949 quality control system

Team of 16 quality engineers, responsible for product quality.

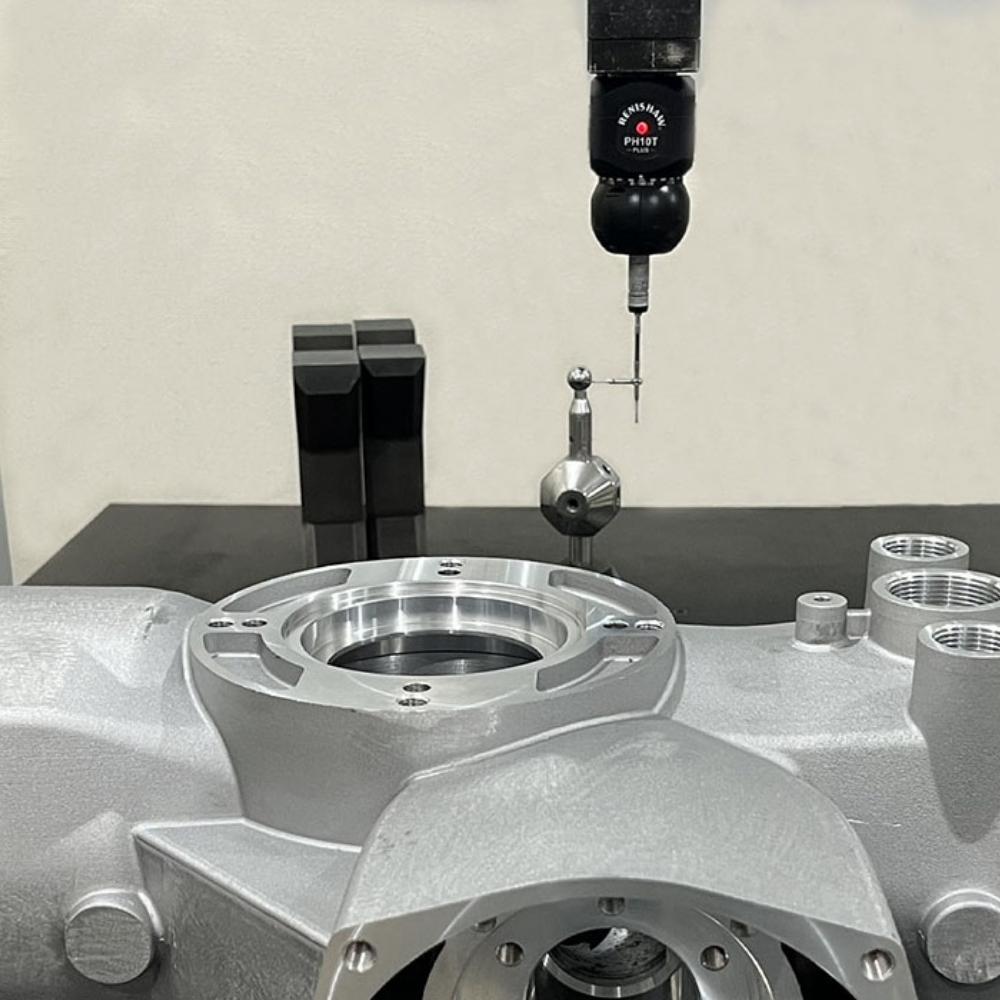

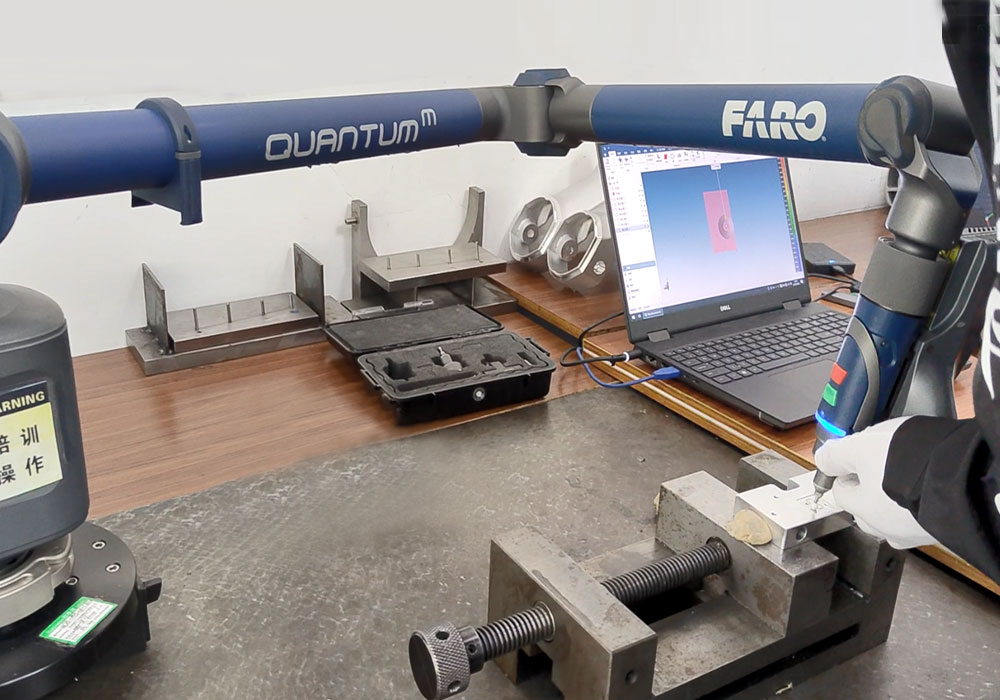

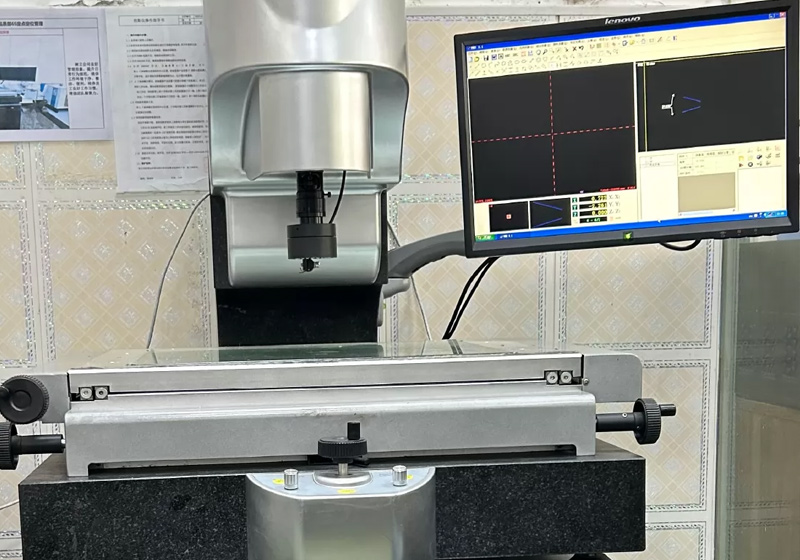

15 sets of A-class testing equipment, including Spectrometer, 3D scan, X-ray, ZEISS CMM, etc.

All products need to pass the whole process inspection, first and last parts, inspection and shipping final inspection.

All testing equipment is regularly calibrated and the record is traceable.

All products shipped to meet ROHS requirements, Reach requirements, providing EN10204 3.1 certification, CBAM data.

Product traceability, according to the product batch number to trace any shipment from the raw material incoming inspection to the warehouse materials, process inspection records, product production process parameters, both equipment and operators and other records, etc.

Complete Quality Inspection Equipment

Innovaw produces aluminum and zinc castings, which are widely distributed in different industries and for different specific applications, which have completely different inspection requirements for castings. In order to ensure that the castings of different characteristics and grades are subject to specific inspection requirements, Innovaw has spent a large amount of money to set up a complete set of inspection equipment, including Spectrometer, 3D scan, X-ray, ZEISS CMM, etc. The equipment is the leading brand in the industry, and at the same time, we have set up a perfect equipment management and maintenance system to ensure the accuracy of each inspection. At the same time, we have established a perfect equipment management and maintenance system to ensure the accuracy of each inspection.

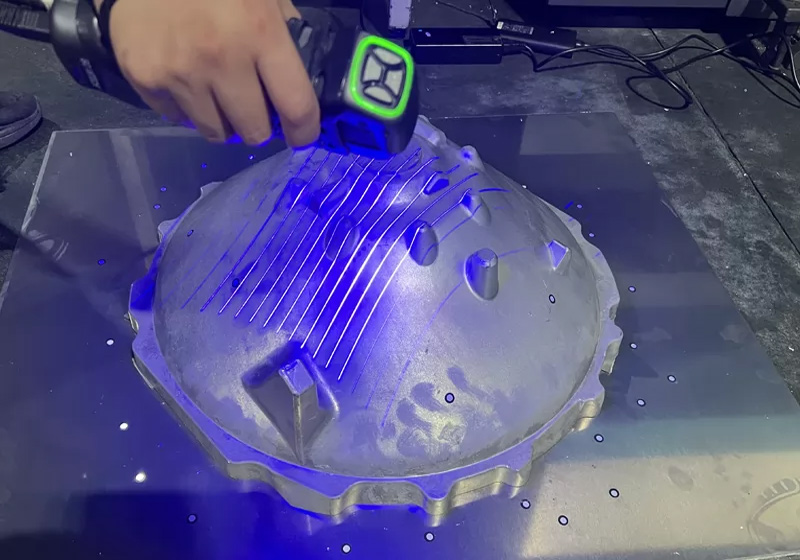

Industrial-Grade 3D Scanning Measurement System

Rapid, flexible, and ultra-precise dimensional inspection and assembly validation, especially for complex components. Offers micron-level accuracy for geometric parameters (length, width, hole positions, angles, coaxiality), ideal for small to medium-sized parts.

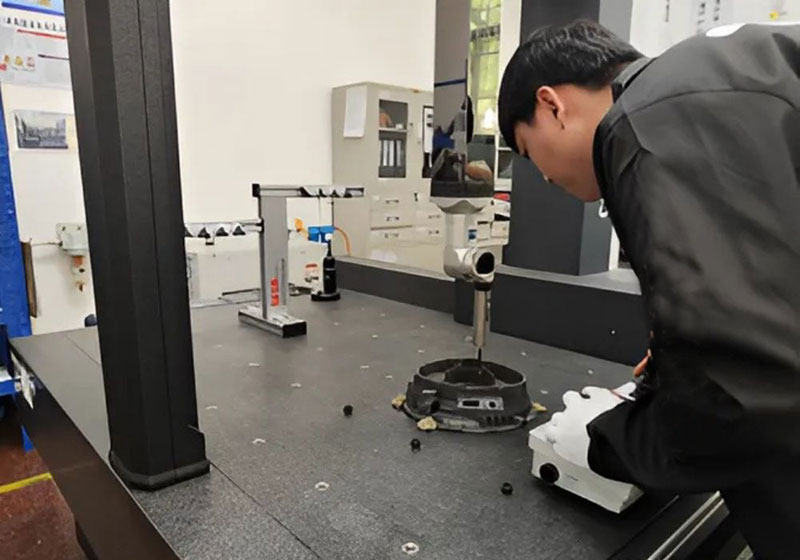

Zeiss CMM

High-precision 3D measurement for geometric parameters: length, width, height, angles, position, flatness, roundness, and coaxiality. Ensures post-production compliance with design specifications and quality standards.

Spectrometer

Analyzes aluminum/zinc alloy composition in under 2 minutes, eliminating material mix-up risks. Detects elements from Li to U with ppm-level accuracy, compliant with ASTM and ISO standards.

X-ray real-time imaging inspection system

Real-time X-ray imaging and 3D tomography for castings and welds, pinpointing internal defects like pores, inclusions, and cold shuts. Features rapid motion control, high efficiency, and multiple modes (DR real-time imaging, CT tomography) to meet diverse inspection needs.

Image Measuring Instrument

Non-contact, high-precision 2D/2.5D measurement using HD cameras, optics, and imaging software. Performs edge/contour detection, CAD-to-real overlay, deviation analysis, and tolerance judgment with ±1–2 μm accuracy.

Metrology-Grade Handheld 3D Scanner

Non-contact 3D scanning for dimensional data collection and analysis. Enables quality inspection, mold/assembly validation, deformation analysis, and structural assessment with 20–50 μm precision.

Mechanical Testing Machine

Highly Qualified Quality Management Team

Innovaw's quality management team consists of a total of 15 highly qualified quality engineers. The team abides by the quality management system standards and has established a perfect quality management and product inspection system. From the first inspection, daily inspection, final inspection to shipment inspection, we have realized the whole process of quality inspection for all products.

Innovaw's quality management team is fully involved in all stages of APQP, and quality management is carried out throughout the entire project lifecycle to ensure that the product meets the customer's quality requirements at every stage from concept to mass production. At the same time, according to VDA6.3 and VDA6.5 audit standards, we realize the whole process of quality management of a product from development, mass production to after-sales support.

In response to quality problems, the quality management team solves the problems through 8D reports.

FAQs

Q1. What are the quality inspection standards for aluminum castings?

Aluminum casting quality inspection typically follows standards like ISO 9001, ASTM B179/B85, and customer-specific requirements covering dimensions, mechanical properties, and surface defects.

Q2. What is the difference between quality system 16949 and ISO9001?

IATF 16949 adds automotive-specific requirements to ISO 9001, including stricter process controls, defect prevention, and customer-supplier collaboration for the automotive industry.