PPAP

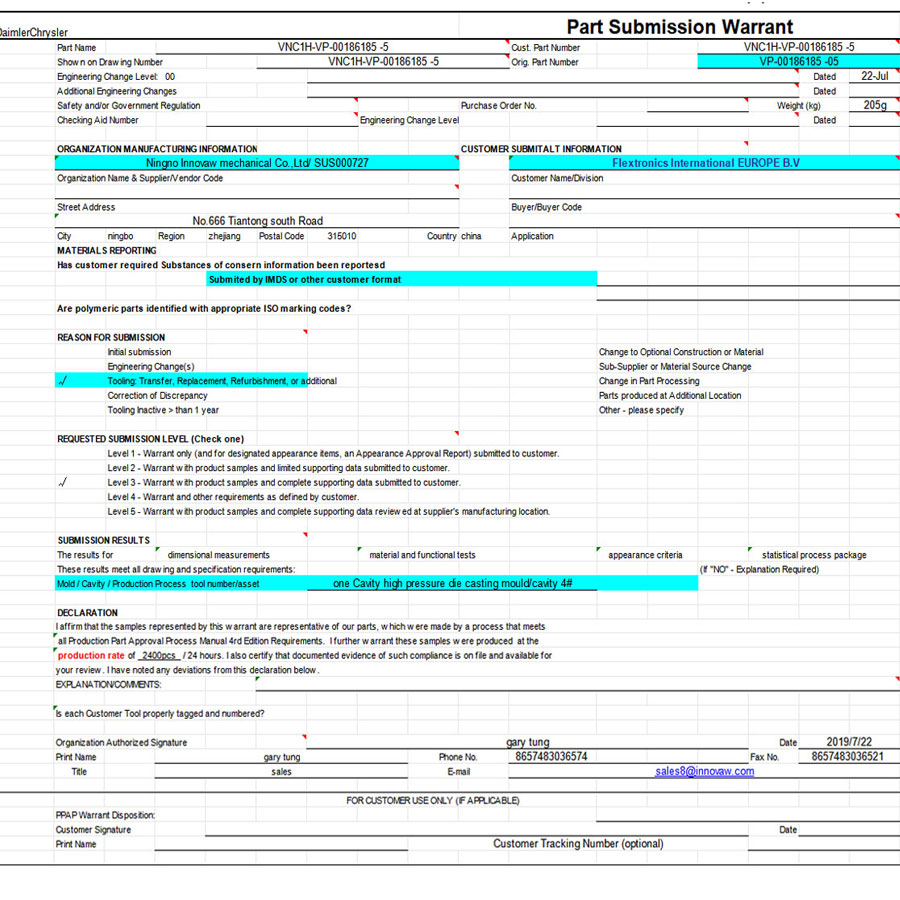

PPAP (Production Part Approval Process) is one of the core requirements within the automotive industry's quality management system. It aims to ensure, through a systematic validation process, that production parts meet customer design and quality specifications prior to mass production.

As a critical output stage within the APQP (Advanced Product Quality Planning) process, PPAP holds a central position in the APQP workflow. Through PPAP, companies can demonstrate to customers, via data and documentation, that their production processes, quality control, and product performance are fully prepared to consistently produce compliant products in volume.

Innovaw is committed to providing high-quality metal component manufacturing services to global customers. Prior to mass production of any product, we provide complete PPAP documentation and secure formal customer approval. Our specific practices include:

• Cross-departmental Collaboration Mechanism

We establish a PPAP project team comprising multiple departments—Quality, Process, Production, Engineering, and Project Management—engaging from the initial product development planning phase. This ensures compliance with APQP and PPAP requirements throughout every stage: design, tooling development, prototyping, and mass production.

• Documented and Data-Driven Management

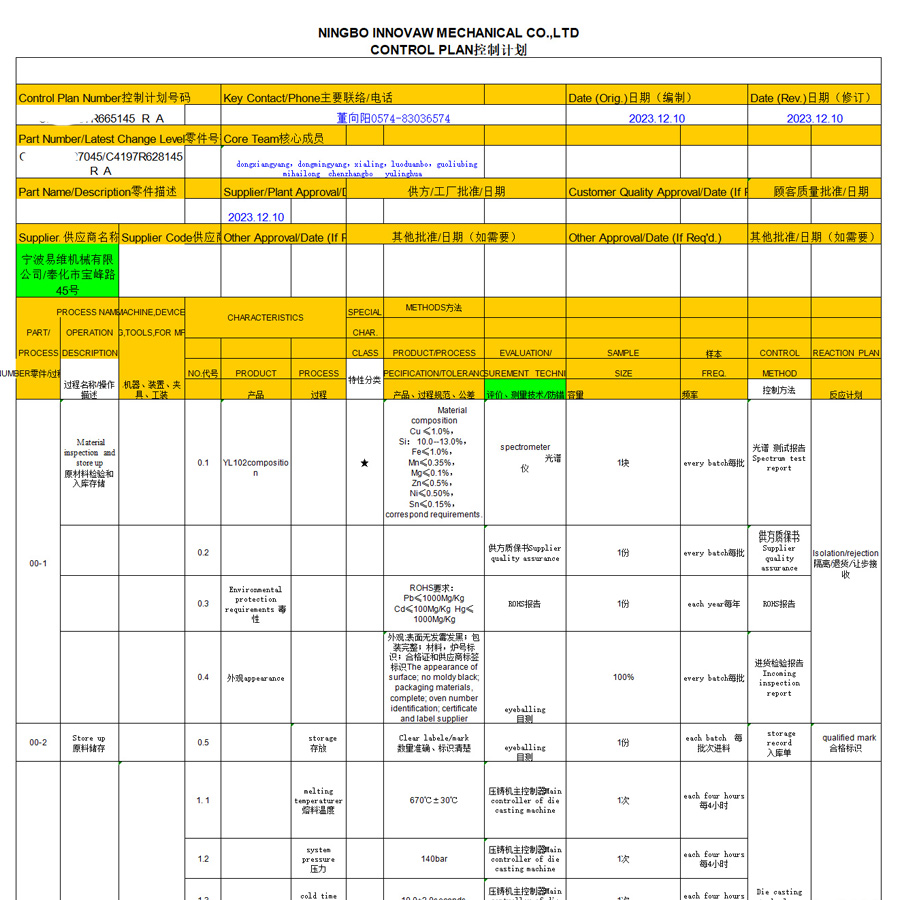

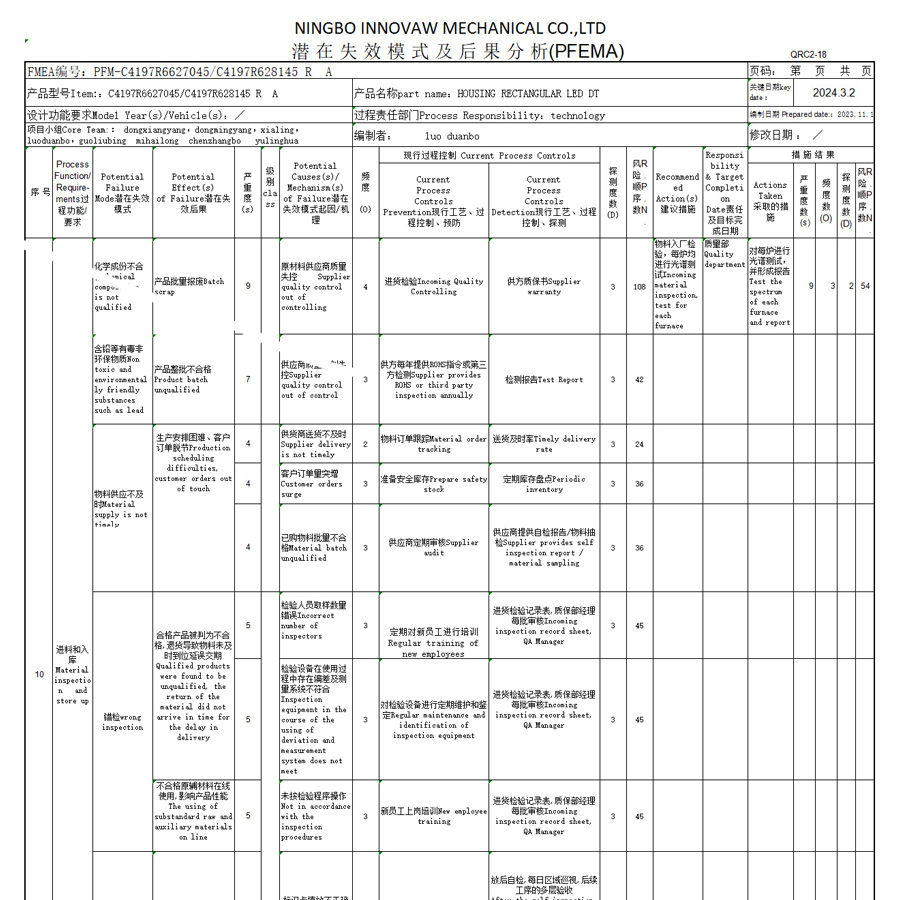

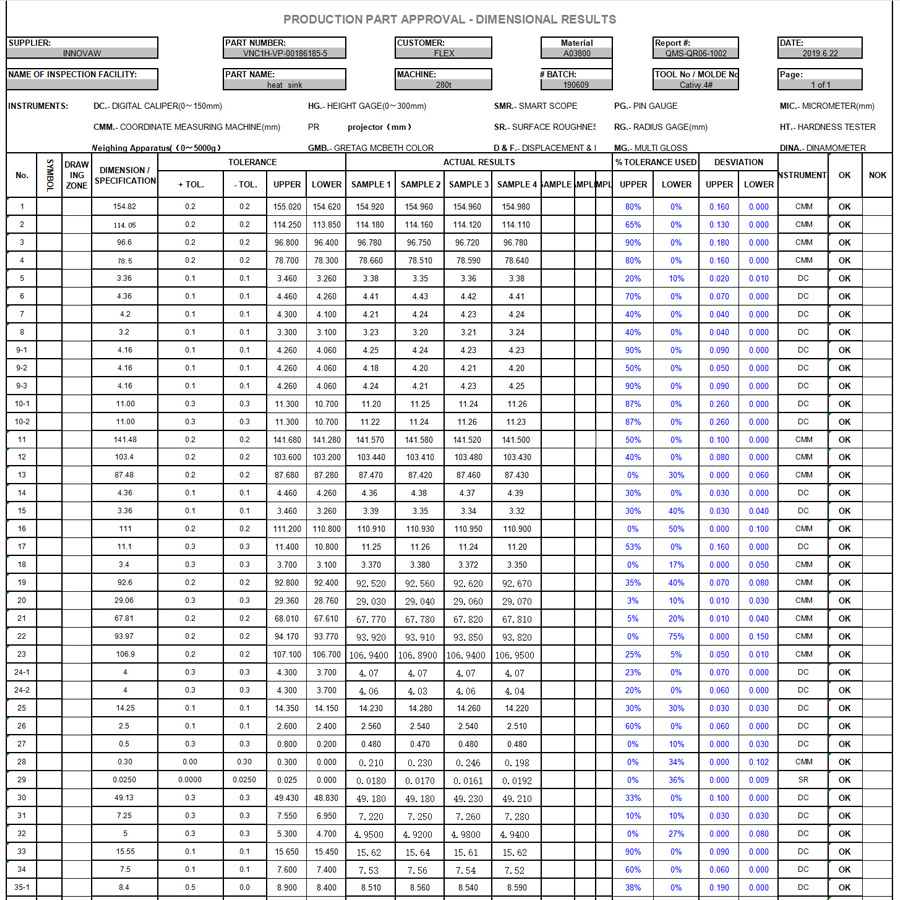

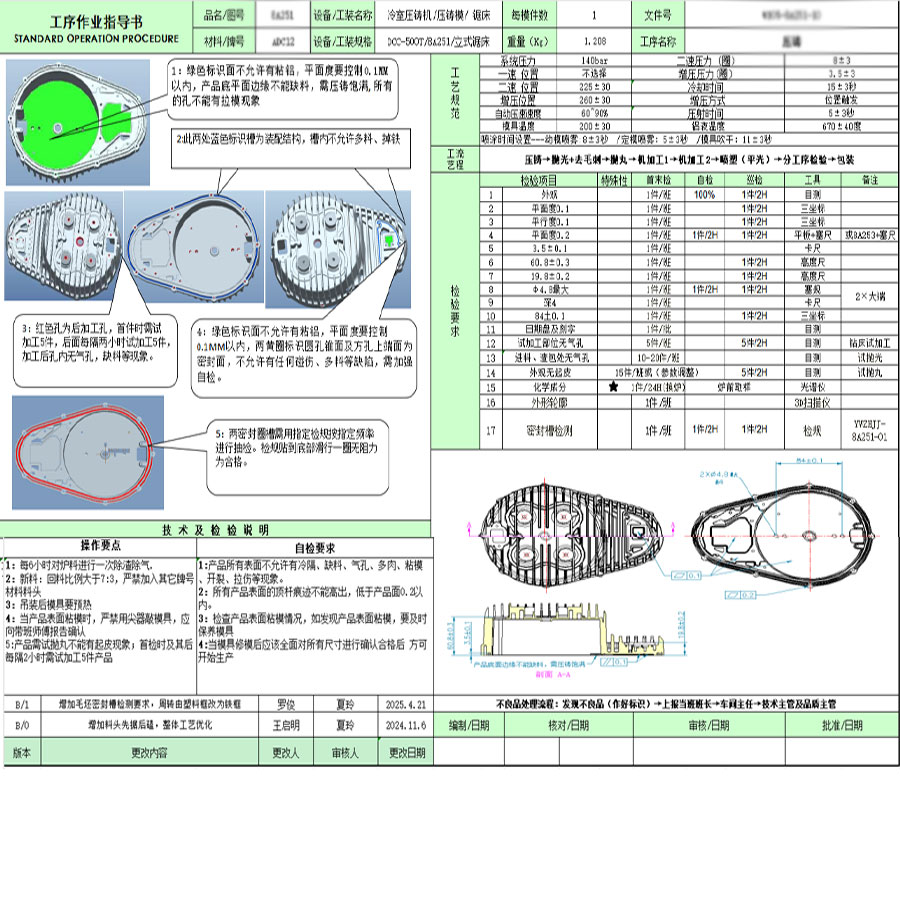

Our company maintains a comprehensive PPAP documentation system, including design records, control plans, process flow diagrams, FMEA (Failure Mode and Effects Analysis), MSA (Measurement System Analysis), SPC (Statistical Process Control), and initial sample inspection reports. Version control and archiving are managed through a digital system, enabling traceable and responsive management practices.

• Rigorous Sample Verification Process

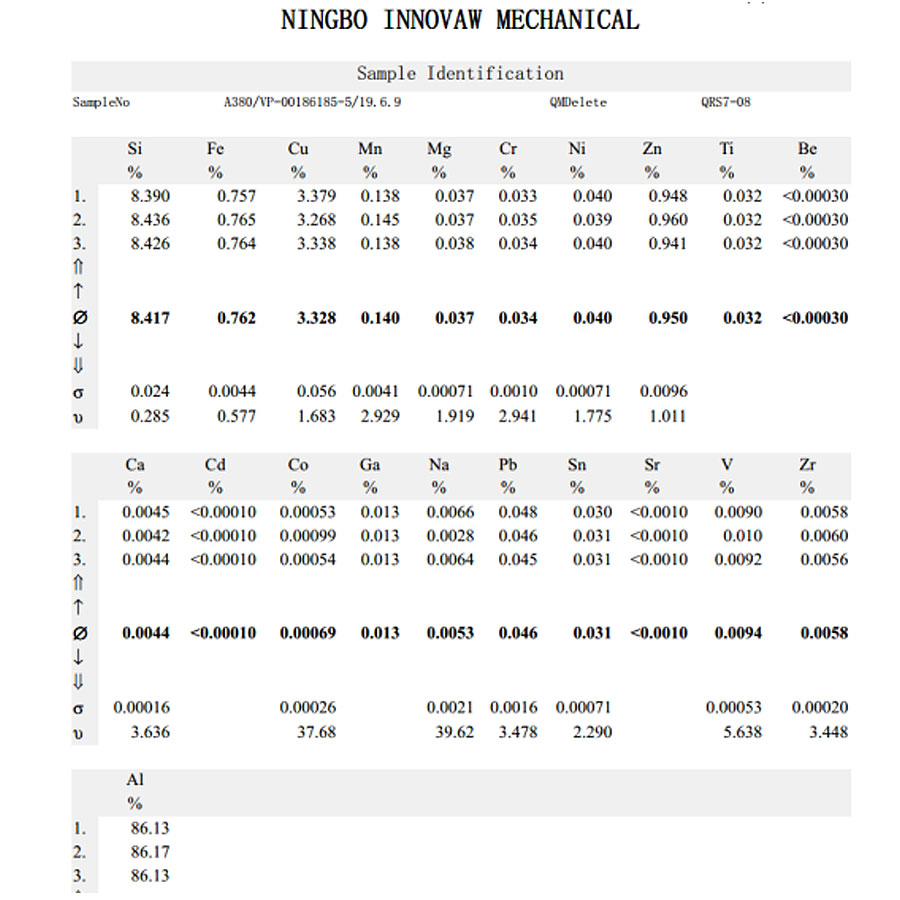

During initial production, we conduct comprehensive inspections and verifications per PPAP requirements, including dimensional checks, chemical composition analysis, X-ray flaw detection, and mechanical property testing to ensure all characteristic metrics meet customer standards.

• Continuous Improvement and Customer Communication

We regularly update control plans and FMEA content based on customer feedback and internal audit results, continuously optimizing process capability (Cpk, Ppk metrics) to ensure stability and consistency during mass production. Simultaneously, we maintain transparent communication with customers through PPAP documentation to strengthen trust and collaboration.

Currently, we provide comprehensive PPAP documentation per customer requirements, covering both castings and machined components, achieving a 95% approval rate. Practice demonstrates that our robust PPAP process significantly reduces product defect rates while enhancing on-time delivery performance and customer satisfaction.

Sample Quality Documents

Material Test Reports

Control Plan

PFEMA

Dimensional Results

Standard Operation Procedure