Project Brief

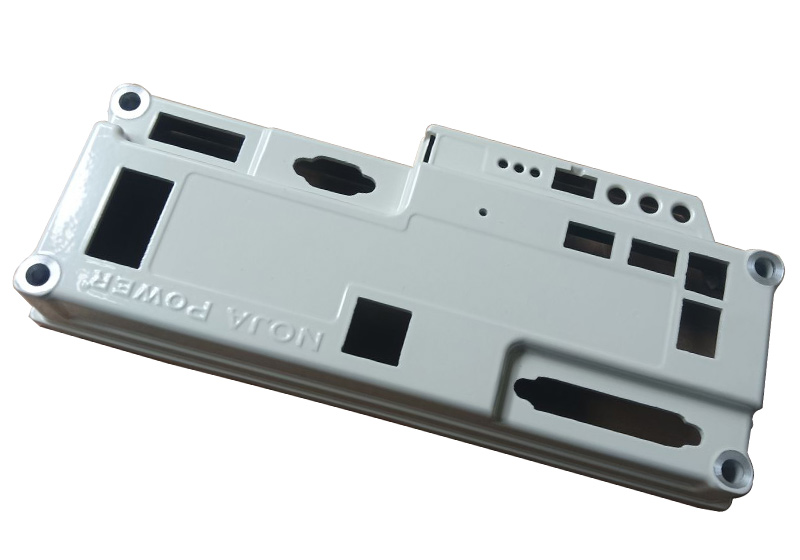

This is a customized agricultural machinery component, applied in equipment such as corn harvesters and tractors.

1. Product Standards & Requirements: Material: AISi6Cu4Zn; Dimensional tolerance class: ISO 8062-CT8; Minimum dimensional tolerance: ±0.1 mm; Surface free of visible defects; Surface roughness: Ra6.3µmµm; PPAP approval must be completed and passed before mass production.

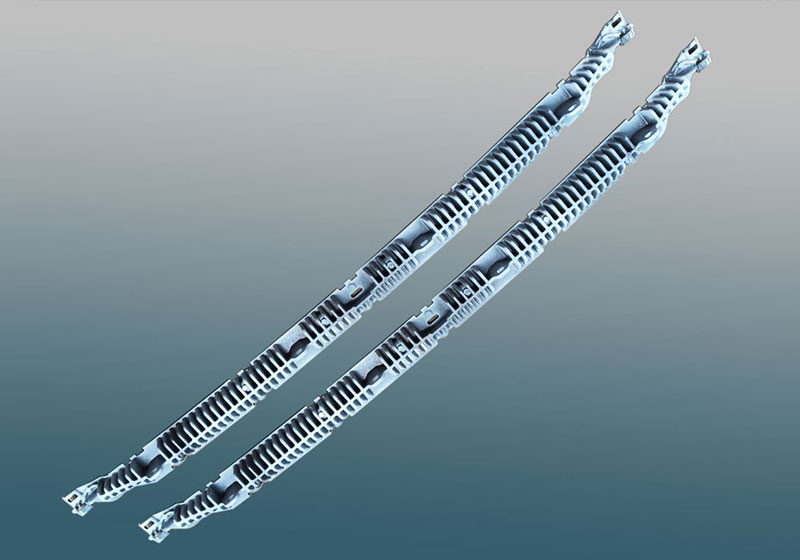

2. Product Challenges: The component features a completely rotational structure, which places high demands on the gating system design. During machining, fixtures cannot achieve physical error-proofing. Additionally, the part contains multiple tubular holes, which are prone to forming air stagnation zones.

The finished product must not only demonstrate excellent machining accuracy and surface finish, but also provide high thermal conductivity, corrosion resistance, lightweight design, and ease of installation and maintenance. Overall, this project presents a certain level of difficulty, posing a comprehensive test of our mold design capability, machining capability, quality control, and delivery performance.

Development Process

1. Following the Advanced Product Quality Planning (APQP) process, we established a project development team consisting of a mold designer, casting engineer, machining engineer, measurement engineer, quality engineer, and sales engineer, ensuring a quality-centered approach throughout the entire product development cycle.

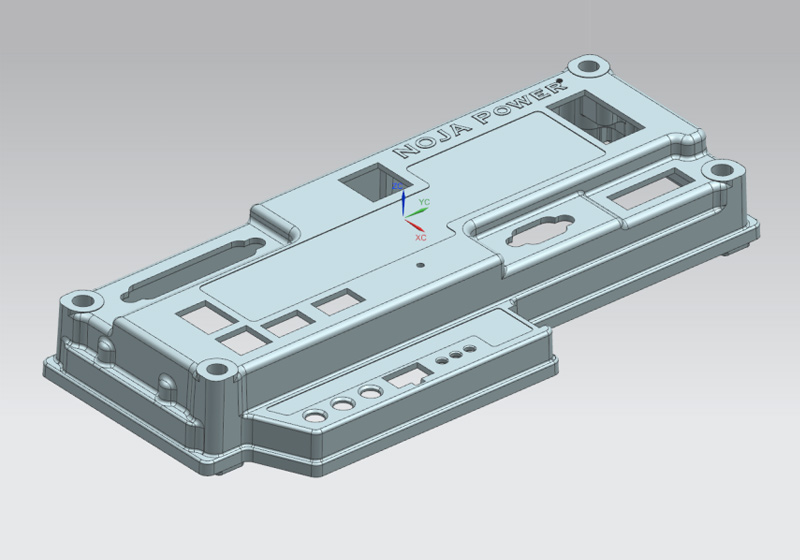

2. Through DFM analysis, we optimized some structural details of the product to enhance manufacturability, and established mutually agreed technical specifications and quality standards with the customer.

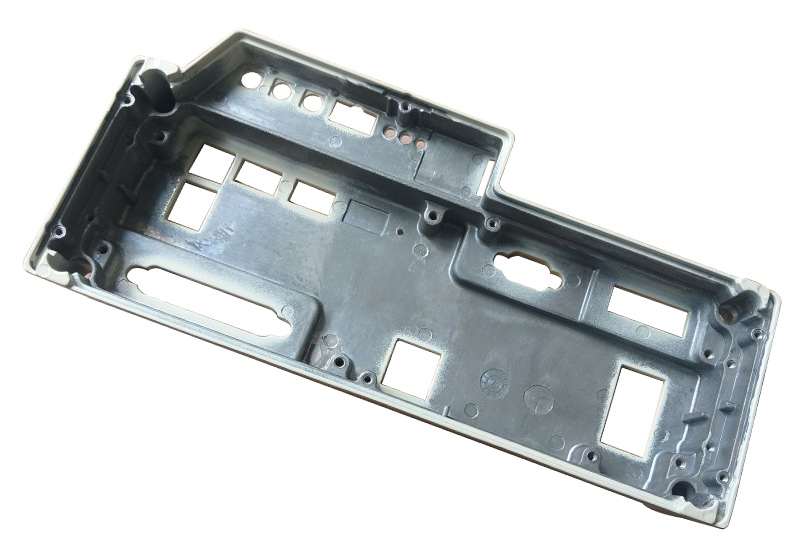

3. Based on material characteristics and the core design elements of this product, considering technical feasibility, quality stability, and cost control, we ultimately selected the process route of gravity casting + CNC precision machining.

4. Technical engineers conducted mold design reviews, mold design and simulation, and flow analysis to predict and optimize key challenges and process parameters, providing the customer with a die-casting simulation analysis report.

5. In the subsequent practical stages, we gradually verified the solution, identified issues, and implemented improvements as follows:

• Issue: X-ray inspection after mold trials revealed local porosity exceeding acceptable limits.

- Solution: Redesigned the threaded holes into pin structures to eliminate porosity.

• Issue: Due to the fully rotational structure, fixtures could not physically prevent incorrect orientation during machining.

- Solution: Enhanced the work instruction documentation to ensure clear and accurate descriptions and added directional arrow markings on the casting blanks to guide correct positioning.

A complete inspection process was implemented, including first article inspection, in-process inspection, and final inspection before shipment, with full data recording and traceability to ensure all quality data are verifiable.

Meanwhile, during development, we established standardized documentation such as FMEA, SPC, MSA, and Process Control Plans, ultimately completing the PPAP documentation, which was approved by the customer.

The finished aluminum die-cast agricultural machinery component demonstrates excellent performance and precision, along with outstanding thermal conductivity, corrosion resistance, lightweight construction, and protective properties. It is also easy to install and maintain. The final product fully achieved the customer’s design goals, providing a higher-performance and more reliable solution for similar component designs.

Production Process

Mould making→High Pressure Die Casting→Cutting the sprue and riser→Polishing→Deburring→CNC Machining→Powder coating→Reaming→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.

Share your thoughts

Showing

6

of

0

reviews