Project Brief

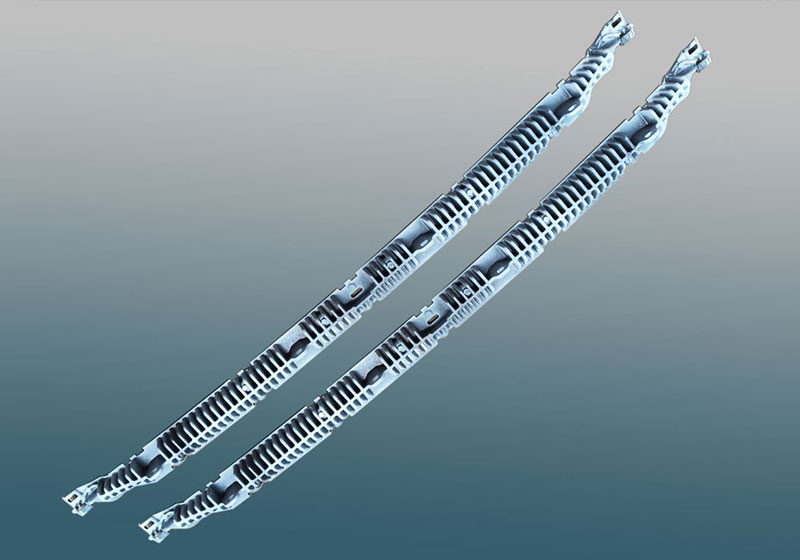

This is a customer-customized marine connector aluminum casting, serving as a critical component for connecting marine equipment.

1. Product Standards and Requirements: Material A356 T6, full-dimension tolerance grade ISO 2768-mk, minimum dimension tolerance ±0.05mm, surface defect-free (surface roughness Ra6.3µm), internally defect-free, and must pass international classification society certification. PPAP approval must be completed and passed prior to formal mass production.

2. Product Challenges: Requires international classification society certification.

The overall project presents significant difficulty, particularly testing our standardized product certification capabilities and quality control capacity.

This marine-grade aluminum casting not only delivers outstanding mechanical properties and machining precision but also offers excellent corrosion resistance, lightweight construction, superior protection, and ease of installation and maintenance. The finished product fully meets the customer's design objectives, providing a higher-performance and more reliable solution for marine component design.

Production Process

Mould making→Gravity Casting→Cutting the sprue and riser→Grinding→CNC Machining→Shot blasting→Packaging & inspection

Production Show

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.

Share your thoughts

Showing

6

of

0

reviews