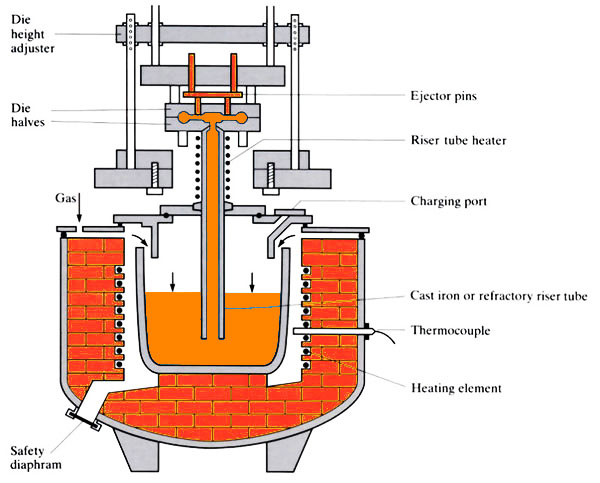

- Fix the mold above the holding furnace and preheat the mold to ensure uniform cooling.

- Molten aluminum is stored in a sealed furnace below the mold. Gas pressure (usually 0.06~0.15 MPa) is applied and the metal is pushed upward into the mold cavity through an ascending tube.

- After the cavity is filled with liquid aluminum, the pressure continues to build up to the crystallization pressure and is maintained until the casting is fully solidified. The casting temperature and pouring temperature are controlled to realize the solidification of the casting from the very edge.

- When the casting is solidified, release the pressure, open the mold and remove the casting.

- After solidification, the mold opens, the ejector bar pushes the part out, and a robotic arm grabs the casting onto a conveyor belt on the side.

- Finish the casting by removing excess material such as risers or sprues and applying other surface treatments.

Low Pressure Die Casting

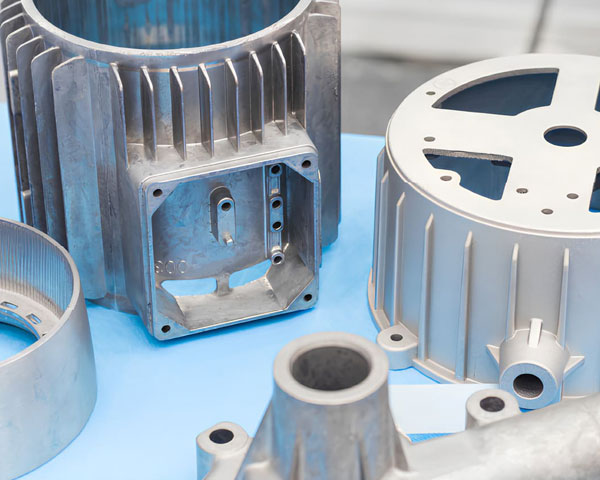

Low Pressure Die Casting (LPDC) is a metal casting process in which molten metal is introduced into a mold cavity at a controlled low pressure and cooled to produce a casting. Unlike high-pressure die casting, LPDC is primarily used to produce parts with excellent mechanical properties and is well suited for large, complex parts in medium production volumes. Low pressure casting is typically used to produce parts made from aluminum.

Advantages of low pressure die casting:

Improved Mechanical Properties: Denser castings with fewer defects.

Controlled Cooling: Results in a uniform grain structure and better dimensional accuracy.

Medium Complexity: Suitable for parts that are more complex than gravity castings but less intricate than high-pressure die castings.

Material Efficiency: Minimal turbulence reduces waste.

Reusable Molds: Permanent molds lower long-term costs compared to sand casting.

Low Pressure Die Casting in Innovaw

Innovaw's low pressure die casting line has a total of 15 fully automated low pressure die casting machines, including molten aluminum units, aluminum transport units, scrap conveyor mechanisms and product processing units, and is also equipped with an automated control system. Our low pressure die casting products cover automotive manufacturing, aerospace, robotics, industrial equipment, medical devices, marine, energy and other industries. The castings range in size from 100mm-1000mm in length, 50mm-800mm in width, 40mm-500mm in height, and from 500g to 300kg in weight, with a daily production capacity of 8-10 tons.

Low Pressure Die Casting Products Cases

Material Scope

Innovaw's foundry complies with ASTM, JIS, DIN, ENAC, ISO, and GB material specifications. Common aluminum alloy grades suitable for low-pressure die casting processes are as follows:

- Aluminum

ASTM-A319, A413, A355, A356, A357

JIS-AC2B, AC4D, AC4C, AC3A, AC4A

DIN-AlSi7cu4, AlSi5cu1Mg, AlSi7Mg, AlSi12, AlSi9Mg, AlSi12Cu2Mg1, AlSi6Cu4

ENAC-45000, 45300, 42100, 44100, 43300

How Low Pressure Die Casting Works

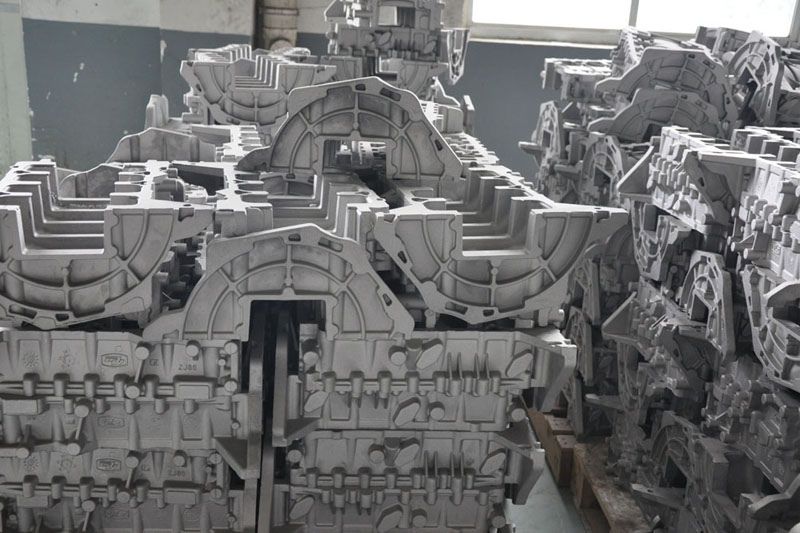

Low Pressure Die Casting (LPDC), as a manufacturing process used to produce metal parts, is usually made of aluminum metal as raw material with high precision, excellent surface finish and outstanding mechanical properties. After receiving customer drawings, Innovaw engineers conduct DFM analysis to design and manufacture corresponding low-pressure die casting molds. The process then proceeds to die casting production, with the specific workflow as follows:

Why Innovaw Low Pressure Die Casting

Innovaw's primary mission is to meet customer expectations in quality, delivery, and performance. Our low pressure die casting process exceeds our customers' expectations in terms of production capacity, technical support, quality control and service.

Production Capability

After more than 20 years of development, Innovaw has established a perfect low pressure die casting production system, equipped with standard workshops and advanced equipment, fully applying ERP, robot automation and MES visualization management, with a daily capacity of 8-10 tons.

We have perfect production management process, high quality management team and workers. Every day, more than 20 production management experts and hundreds of workers provide professional production services to our customers.

From mold development to PPAP approval, serialization, LPDC, processing and surface treatment production, the whole process provides one-stop service to create value for customers.

Technical Capability

We have a technical team of more than 20 engineers and industry experts to provide comprehensive support.

Relying on our rich experience, we provide one-stop service from DFM analysis, 3D mold design, mold flow analysis to rapid prototyping, helping our customers quickly realize high-quality products from drawings.

We specialize in providing effective engineering solutions to help customers reduce cost and improve quality.

We are experienced in the design and production of complex geometric products, and are especially good at using sand cores to realize complex mold cavity structures.

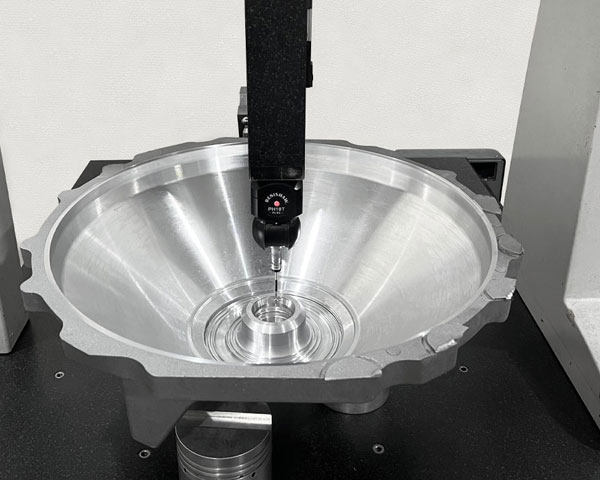

Quality Control

Our low pressure die casting products take IATF 16949 quality management system as the implementation standard.

We utilize core tools such as APQP, FMEA, PPAP, MSA, SPC, etc. to achieve production process control.

Process audits are regularly conducted through VDA6.3 and product audits are regularly conducted through VDA6.5.

Regularly use 8D analysis and report to deal with customer complaints and solve problems from the root cause.

All products need to pass the whole process inspection, including Spectrometer, 3D scan, X-ray, ZEISS CMM, etc. from the first article to final inspection.

Why choose low-pressure die casting to manufacture your products?

In the field of precision metal parts manufacturing, process selection directly affects the quality, cost and market competitiveness of products. As an efficient and controllable metal forming technology, low-pressure die casting has become the preferred solution for many high-demand products due to its unique process characteristics.

1. What kind of products are suitable for low-pressure die casting?

If you need to purchase aluminum metal parts that meet the following characteristics, then it is suitable to use low-pressure die casting process:

- 1. Complex thin-walled structures: such as automobile wheels, engine cylinders or electronic equipment housings. These products usually need to be both lightweight and high-strength. Low-pressure die casting can accurately fill complex cavities and avoid the cold shut and insufficient pouring defects of traditional casting.

- 2. High surface quality requirements: If the product needs to be used directly as an appearance part (such as high-end lamp brackets and decorative parts), low-pressure die casting can reduce surface pores through smooth filling, and the surface finish after molding can reach Ra 3.2μm or above.

- 3. High internal density requirements: Suitable for parts such as hydraulic valve bodies and aerospace joints that need to withstand high pressure or high loads. Low-pressure die casting significantly reduces internal shrinkage defects through pressure compensation.

- 4. Medium and large thick-walled castings: Low-pressure die casting has stable filling and is suitable for producing castings weighing from a few hundred grams to tens of kilograms. In particular, the compensation effect on thick-walled parts (such as automobile chassis brackets) is better than gravity casting.

2. Five core advantages of low-pressure die casting process

For the above product needs, low-pressure die casting has shown irreplaceable technical advantages:

- 1. High material utilization and low cost: The process does not require the setting of risers, the metal recovery rate can reach more than 90%, and the aluminum liquid in the pouring system can be recycled, significantly reducing the waste of raw materials.

- 2. Excellent casting performance: Through constant pressure compensation (usually 0.06~0.15 MPa), the internal structure of the casting is dense, the tensile strength can be increased by 15%~20% compared with gravity casting, and the elongation is optimized simultaneously.

- 3. Precision molding capability: The low-pressure filling speed is controllable (0.5~1.5 m/s), the metal liquid flows smoothly, and can form complex structures with a wall thickness as low as 3mm, and the dimensional accuracy can reach CT6~CT8 level.

- 4. Green and environmentally friendly: The process has low energy consumption, less smoke and dust, and the aluminum liquid oxidation loss rate is less than 1%, which meets the requirements of sustainable development.

- 5. Flexible adaptation to diversified production: It can be used with metal molds to achieve high-efficiency mass production (such as automotive parts), and can also be combined with sand core casting of complex cavities (such as engine cylinder heads), with strong process compatibility.

Whether it is new energy vehicle parts that pursue lightweight and high strength, or consumer electronic products that emphasize surface accuracy, the low-pressure die-casting process can achieve a balance between product production cost and quality through its high material utilization, excellent mechanical properties and precision molding capabilities.