Innovaw Aluminum Castings in the LED Lamp Industry

In more than 20 years of aluminum casting development practice, we have actually developed and produced more than 3,000 kinds of different parts, among which LED light fittings occupy an important position, including all kinds of automotive LED fittings, street lamp LED fittings, industrial and mining LED fittings, etc.. We strictly follow the IATF 16949 quality management system to control the quality of LED accessories with international mainstream quality standards. Committed to lean production and continuous improvement, we are able to meet the changing needs of the lighting industry.

For the different requirements of aluminum casting for LED light fittings, Innovaw mainly applies aluminum high pressure die casting, low pressure die casting, gravity casting and cnc machining process for development and production, and has won the trust of our customers with high reliable and consistent quality and customer-oriented service. We maintain long term relationships with our customers in the lighting industry with consistent quality control, and are considered a trusted partner by our customers to meet their needs for high precision and critical performance LED accessories.

LED lamps and lanterns industry application of the current situation of aluminum castings

Aluminum castings are suitable for key parts of various LED lights, such as lamp body, lampshade, lamp shell, etc. due to its excellent thermal conductivity, light weight and high strength, corrosion resistance, easy processing and other characteristics. It has become an irreplaceable main material in the LED lighting industry.

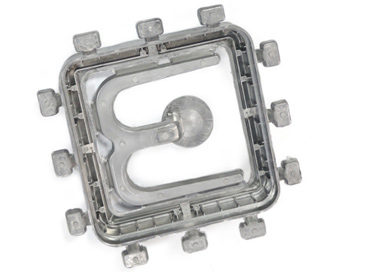

Explosion-proof lamp housing

LED light aluminum casting cases

The significance of applying aluminum castings in LED industry

Aluminum casting parts have become a core solution in LED light manufacturing due to its unique material properties and process advantages. The main performance in.

- Light weight and high strength

- Excellent thermal conductivity

- Corrosion and oxidation resistance

- Complex structure molding capability

- Total life cycle cost optimization

- Environmentally friendly and recyclable

Therefore, in all kinds of LED lamps and lanterns, aluminum castings occupy an important position in LED lamp components. The application of aluminum casting brings many positive significance:

1. Enhance the heat dissipation performance, prolong the life of LEDs

2. Realize lightweight design, reduce installation and transportation costs

3. Optimize the appearance and structure, enhance product competitiveness

Aluminum castings can achieve complex modeling one-piece molding, to meet the LED lamps and lanterns on the shell structure of the diversified, beautiful needs.

4. Enhance corrosion resistance, adapt to harsh environments

After surface treatment (powder coating, anodic oxidation, etc.), aluminum castings have good corrosion resistance, ultraviolet resistance, anti-aging ability, so that the LED lamps and lanterns can be used for a long time.

5. Support green manufacturing and sustainable development

Aluminum can be recycled, recycling energy consumption is only about 5% of the original production, in line with the LED industry to promote environmental protection, energy saving and emission reduction trends.

. Reduce Total Cost of Ownership

By improving the reliability of LED luminaires, reducing the frequency of maintenance, and prolonging the life cycle, the application of aluminum castings ultimately helps customers to reduce costs.

Innovaw provides aluminum casting solutions for the lighting industry

With the rapid development of LED lighting technology, different application scenarios put forward higher requirements on the performance, life and appearance design of lamps. As a professional aluminum casting manufacturer, we deeply understand the multiple needs of LED lamps and lanterns for heat dissipation, strength, light weight and aesthetics, and provide efficient and reliable aluminum casting solutions for different application scenarios.

1. In practical applications, LED lamps are characterized by complex specifications and diverse needs, Innovaw strictly follows the IATF 16949 quality management standards and implements strict quality management in the whole production process to ensure that the aluminum castings for LED lamps and lanterns are continuously improved in terms of dimensional accuracy, denseness, strength and surface quality.

2. For different applications under the LED lamps and lanterns, need different aluminum casting process to adapt to the best program. For example, outdoor street lamps have to adapt to a variety of harsh weather conditions, industrial and mining lamps with dusty environments, etc., which require components designed to meet the harsh requirements of different environments.

Innovaw focuses on various aluminum casting technologies, including high pressure casting, low pressure casting, gravity casting and sand casting, which can flexibly respond to the performance requirements and process challenges of different parts.

3. Innovaw provides a variety of surface treatment services, including powder coating, painting, anodizing, fluorocarbon coating, etc., to enhance the weathering and UV resistance of aluminum castings, corrosion resistance, and the appearance of texture and color diversity.

4. In the current competitive environment, flexible inventory management of parts and components is one of the important core demands of users, Innovaw responds to the needs of users, through the optimization of self-developed mold design, advanced production management system, fast logistics services, to provide customers with efficient supply chain management services.

5. In response to different product development needs, Innovaw's development engineers and industry experts work closely with customers to reduce product design defects through DFM analysis, mold flow analysis and other tools, to achieve rapid realization of products from drawings to finished products.

In the future, we will continue to be driven by innovation, constantly improve process capabilities and product performance, and work hand in hand with our customers to create a highly efficient, green and intelligent LED light future.