Investment Casting: Process Overview, Key Benefits, and Industrial Applications

Why is investment casting increasingly chosen by manufacturers when component complexity, material performance, and dimensional precision must all be achieved at once? As industries push for lighter designs, tighter tolerances, and more integrated structures, traditional manufacturing methods often struggle to keep pace with these evolving demands.

This article explains how investment casting addresses these challenges by combining a controlled production process with exceptional design freedom and broad material compatibility. From aerospace and medical devices to automotive and energy applications, engineers, product designers, and sourcing managers are turning to investment casting to reduce machining, improve consistency, and meet rising quality expectations driven by modern manufacturing trends.

In the following sections, we break down the investment casting process, its key benefits, and real-world industrial applications—highlighting why selecting the right casting method matters and how informed decisions can directly impact performance, cost, and reliability. Continue reading to gain a clear, practical understanding of investment casting and its role in today’s manufacturing landscape.

Table of contents

- What Is Investment Casting

- Investment Casting Process

- Materials Used in Investment Casting

- Investment Casting: Advantages and Limitations

- Comparison with Other Manufacturing Processes

- Industrial Applications

- How to Choose an Investment Casting Supplier

- Conclusion

What Is Investment Casting

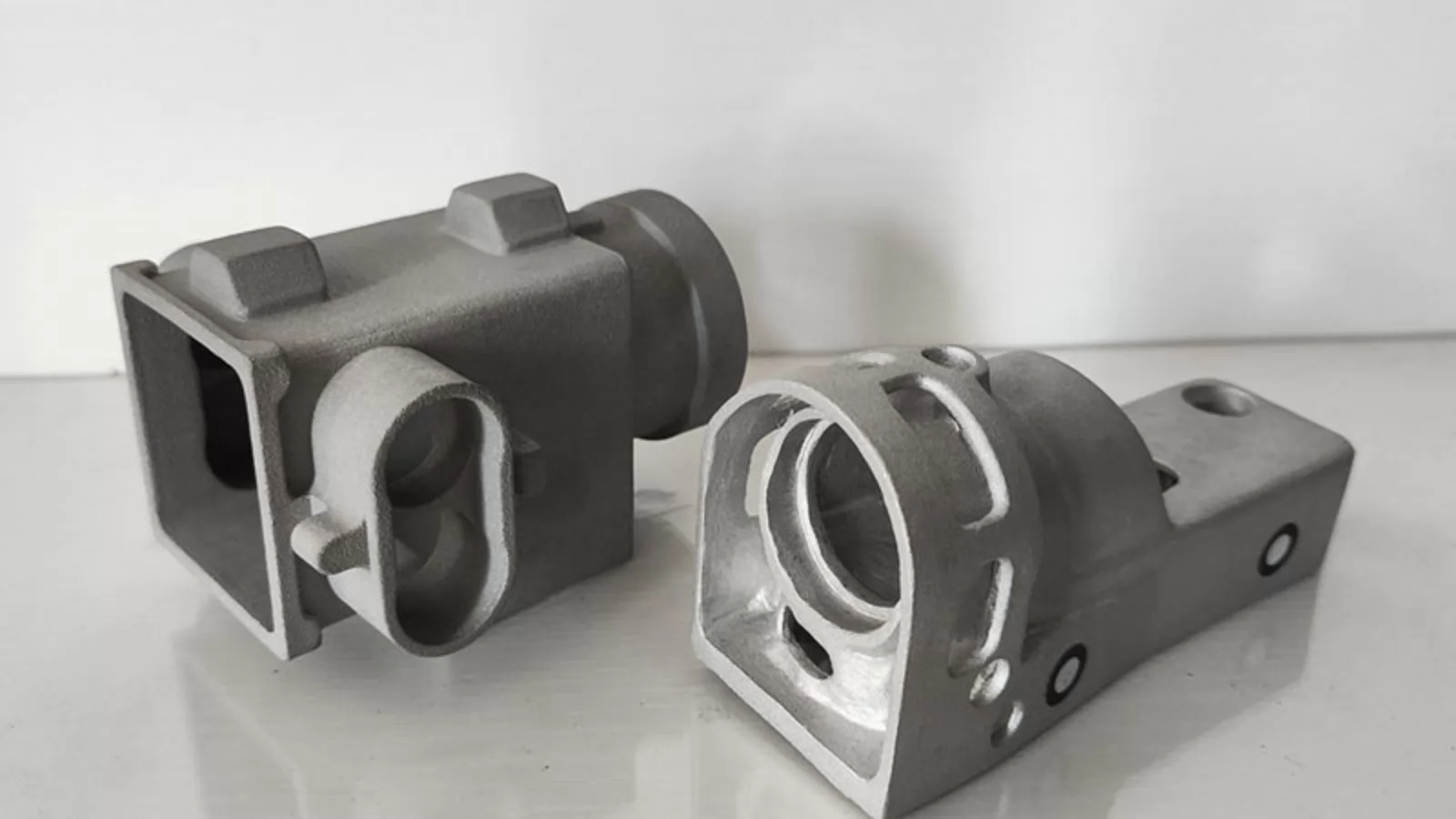

Investment casting, commonly referred to as lost wax casting, is a precision metal casting process used to produce complex metal components with high dimensional accuracy and smooth surface finishes. The process begins with the creation of a wax pattern that replicates the final part geometry. This pattern is coated with multiple layers of refractory ceramic material to form a rigid shell. Once the wax is removed, molten metal is poured into the ceramic mold, and after solidification, the shell is broken away to reveal a near-net-shape casting.

Although the basic principle of investment casting has existed for centuries, the process has evolved significantly with the development of industrial-grade waxes, advanced ceramic shell systems, and precise temperature and metallurgical control. These advancements transformed investment casting from an artisanal technique into a reliable industrial manufacturing method capable of meeting modern engineering standards and repeatability requirements.

Today, investment casting plays an important role in modern manufacturing where component complexity, material performance, and dimensional precision must be achieved simultaneously. The process enables the production of intricate features, thin walls, and integrated structures that are difficult or inefficient to manufacture using conventional machining or forging methods. By reducing material waste and minimizing secondary operations, investment casting supports efficient production and consistent quality across a wide range of industrial applications.

Investment Casting Process

The investment casting process consists of a controlled sequence of manufacturing steps designed to reproduce complex part geometries with high dimensional accuracy and consistent metallurgical quality. Each stage of the process directly influences surface finish, dimensional tolerance, and structural integrity of the final casting.

1. Wax Pattern Production

Wax patterns are produced by injecting molten wax into a precision metal die that defines the external geometry of the final component. The wax formulation is selected to ensure dimensional stability, low shrinkage, and clean removal during the dewaxing stage. After ejection from the die, each wax pattern is inspected for surface integrity and dimensional consistency.

2. Pattern Assembly and Tree Formation

Individual wax patterns are attached to a central wax sprue to form a tree-like assembly that serves as the gating and feeding system. The configuration and orientation of each pattern are engineered to promote uniform metal flow, controlled solidification, and reduced risk of shrinkage-related defects.

3. Ceramic Shell Building

The assembled wax tree is repeatedly immersed in a ceramic slurry and coated with refractory sand to form a multilayer ceramic shell. Each layer is dried under controlled environmental conditions. Shell thickness and layer count are determined based on part geometry, size, and alloy requirements to ensure sufficient strength during pouring.

4. Dewaxing and Shell Preheating

After the ceramic shell has fully cured, the wax is removed using an autoclave or thermal process, leaving a precise mold cavity. The shell is subsequently preheated to eliminate residual wax, enhance mold strength, and reduce thermal gradients during metal pouring.

5. Metal Melting and Pouring

Metal is melted under controlled conditions using induction or vacuum furnaces to achieve the specified chemical composition and pouring temperature. The molten metal is poured into the preheated ceramic shell to ensure complete mold filling while minimizing oxidation and gas entrapment.

6. Cooling, Shell Removal, and Cut-Off

The filled mold is allowed to cool and solidify according to alloy-specific cooling profiles. Once solidification is complete, the ceramic shell is removed through mechanical or chemical methods. Individual castings are then separated from the gating system by cutting or sawing.

7. Finishing and Quality Inspection

Final processing includes surface finishing operations such as grinding, blasting, or polishing to meet specified surface requirements. Each casting is subjected to dimensional verification and quality inspection using visual examination, coordinate measurement, or non-destructive testing to ensure compliance with applicable standards.

Materials Used in Investment Casting

Material selection is a critical factor in determining the performance, reliability, and cost efficiency of investment cast components. Different alloy systems respond uniquely to the casting process, heat treatment, and service environment, making it essential to align material properties with functional and manufacturing requirements at an early design stage.

Stainless Steel

Stainless steel alloys are commonly specified in investment casting when corrosion resistance, mechanical consistency, and dimensional control must be achieved within a single manufacturing process. Different stainless steel families offer distinct trade-offs between strength, ductility, and environmental resistance.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Austenitic Stainless Steel | ASTM CF8 (304) | General corrosion resistance, formability | Investment Casting | 304 Technical Data |

| Austenitic Stainless Steel | ASTM CF8M (316) | Enhanced pitting and chloride resistance | Investment Casting | 316 Technical Data |

| Martensitic Stainless Steel | ASTM CA15 (410) | Moderate corrosion resistance, high hardness | Investment Casting | 410 Technical Data |

| Precipitation-Hardening Stainless Steel | ASTM CB7Cu-1 (17-4 PH) | High strength with controlled toughness | Investment Casting | 17-4 PH Technical Data |

| Duplex Stainless Steel | ASTM CD3MN (2205) | Strength-to-corrosion resistance balance | Investment Casting | 2205 Technical Data |

In practical investment casting projects, stainless steel selection is typically driven by the balance between corrosion resistance and mechanical performance rather than material strength alone. Austenitic grades favor chemical and environmental resistance, while martensitic and precipitation-hardening grades are preferred when higher hardness or load-bearing capacity is required.

Low Alloy Steel

Low alloy steels are selected for investment casting applications where strength, fatigue performance, and impact resistance are critical. Alloying additions improve hardenability and enable consistent mechanical properties across complex geometries.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Chromium-Molybdenum Steel | ASTM 4130 | Strength with good fatigue behavior | Investment Casting | 4130 Technical Data |

| Chromium-Molybdenum Steel | ASTM 4140 | Higher hardenability and wear resistance | Investment Casting | 4140 Technical Data |

| Nickel-Chromium-Molybdenum Steel | ASTM 4340 | High toughness under dynamic loading | Investment Casting | 4340 Technical Data |

| Low Alloy Case-Hardening Steel | ASTM 8620 | Surface wear resistance after heat treatment | Investment Casting | 8620 Technical Data |

Low alloy steels offer a wider mechanical performance window compared to carbon steels, making them suitable for components subjected to cyclic loads or impact forces. Proper heat treatment plays a critical role in achieving the desired combination of strength, toughness, and wear resistance in investment-cast parts.

Cast Aluminum

Aluminum alloys are commonly specified for investment casting when component weight reduction, thermal conductivity, and dimensional accuracy are primary design considerations. Their solidification behavior allows fine feature definition while maintaining acceptable mechanical performance.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Al-Si-Mg Alloy | A356 | Good strength-to-weight ratio, heat-treatable | Investment Casting | A356 Technical Data |

| Al-Si-Mg Alloy | A357 | Improved ductility and fatigue resistance | Investment Casting | A357 Technical Data |

| Al-Mg-Si Alloy | 6061 | Balanced strength and corrosion resistance | Investment Casting | 6061 Technical Data |

| Al-Zn-Mg-Cu Alloy | 7075 | High specific strength for structural parts | Investment Casting | 7075 Technical Data |

When using aluminum alloys in investment casting, design emphasis is often placed on weight reduction and thermal performance rather than maximum strength. Alloy selection and heat treatment directly influence fatigue behavior and dimensional stability in lightweight structural components.

Carbon Steel

Carbon steels are applied in investment casting when cost efficiency and basic mechanical strength define the primary requirements. Carbon content and subsequent heat treatment allow controlled adjustment of hardness and tensile properties.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Low Carbon Steel | AISI 1010 | Good ductility and weldability | Investment Casting | 1010 Technical Data |

| Medium Carbon Steel | AISI 1020 | Balanced strength and machinability | Investment Casting | 1020 Technical Data |

| Medium Carbon Steel | AISI 1045 | Higher strength after heat treatment | Investment Casting | 1045 Technical Data |

Carbon steel remains a practical option for investment casting when functional requirements are well defined and cost efficiency is a priority. Mechanical properties can be adjusted through controlled carbon content and post-casting heat treatment, enabling consistent performance in general-purpose components.

Superalloy

Superalloys are required for investment casting applications involving prolonged exposure to high temperatures, mechanical stress, and aggressive environments. Their complex chemistries demand precise control over melting and solidification.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Nickel-Based Superalloy | IN718 | High strength retention at elevated temperatures | Investment Casting | IN718 Technical Data |

| Nickel-Based Superalloy | IN625 | Oxidation and corrosion resistance | Investment Casting | IN625 Technical Data |

| Cobalt-Based Superalloy | Mar-M-247 | Creep resistance under thermal loading | Investment Casting | Mar-M-247 Technical Data |

The use of superalloys in investment casting is primarily justified by their ability to maintain mechanical integrity under extreme thermal and mechanical conditions. Successful casting of these materials depends on precise process control to minimize defects and ensure reliable high-temperature performance.

Cast Iron

Cast irons are selected for investment casting where vibration damping, wear resistance, and dimensional stability outweigh tensile strength requirements. Their graphite structure contributes to predictable machining behavior.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Gray Iron | Class 30 | Vibration damping and machinability | Investment Casting | Class 30 Technical Data |

| Ductile Iron | 65-45-12 | Improved toughness and elongation | Investment Casting | 65-45-12 Technical Data |

Cast iron investment castings are typically chosen for their inherent damping capacity and dimensional stability rather than tensile strength. The graphite structure contributes to predictable machining behavior and long-term performance in wear-intensive applications.

Copper Alloy

Copper alloys are used in investment casting when electrical conductivity, thermal performance, and resistance to corrosion or sliding wear are critical to component function.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Tin Bronze | C83600 | Good bearing properties and corrosion resistance | Investment Casting | C83600 Technical Data |

| Aluminum Bronze | C95400 | High strength and wear resistance | Investment Casting | C95400 Technical Data |

Copper alloy investment castings are often specified for functional components where conductivity or wear resistance directly impacts system performance. Alloy composition influences both casting fluidity and service behavior, making early material selection an important design consideration.

Special Alloys

Special alloys are applied in investment casting when components must meet highly specific mechanical, thermal, or chemical performance requirements that exceed conventional alloy systems.

| Alloy Family | Standard / Grade | Key Performance Focus | Manufacturing Route | Reference Document |

|---|---|---|---|---|

| Titanium Alloy | Ti-6Al-4V | High specific strength and corrosion resistance | Investment Casting | Ti-6Al-4V Technical Data |

| Cobalt-Based Alloy | CoCrMo | Wear resistance and biocompatibility | Investment Casting | CoCrMo Technical Data |

| Nickel-Based Alloy | Hastelloy X | Oxidation resistance at high temperature | Investment Casting | Hastelloy X Technical Data |

Special alloys are selected when standard material systems cannot meet application-specific performance limits. Investment casting enables precise control of complex geometries in these materials, supporting applications that demand high reliability under extreme operating conditions.

Investment Casting: Advantages and Limitations

Understanding the strengths and constraints of investment casting is essential for making informed decisions during the design and manufacturing stages. The following points highlight key benefits that make investment casting a preferred choice for precision components, as well as limitations that must be considered to ensure feasibility and cost-effectiveness.

1. Key Benefits

- Dimensional Accuracy: Investment casting delivers precise dimensions and smooth surface finishes, reducing the need for secondary machining.

- Complex Geometry: Capable of producing intricate shapes, thin walls, and fine details that are difficult with other casting methods.

- Material Flexibility: Supports a wide variety of metals and alloys, allowing selection based on strength, corrosion resistance, and other functional requirements.

- Near-Net-Shape Production: Reduces material waste and improves overall production efficiency.

- Reproducibility: Ensures consistent quality for small to medium batch sizes, ideal for precision components.

2. Limitations

- Higher Cost: Production costs are higher compared to simpler casting methods, especially for large-volume runs.

- Long Lead Time: Multiple steps, including wax pattern making and ceramic shell building, extend production time.

- Part Size Limitation: Extremely large or heavy components may be impractical or uneconomical to produce.

- Alloy Challenges: Some metals have casting difficulties due to flow, shrinkage, or solidification characteristics.

- Design Sensitivity: Improper design can lead to defects like porosity, misruns, or surface imperfections.

Comparison with Other Manufacturing Processes

Investment casting is one of several manufacturing methods available for producing metal components. Each process has unique advantages and limitations in terms of cost, precision, complexity, and production volume. The following table provides a direct comparison of investment casting with other common manufacturing techniques to help engineers make informed process decisions.

| Manufacturing Process | Key Advantages | Typical Limitations | Best Applications |

|---|---|---|---|

| Investment Casting | High dimensional accuracy, excellent surface finish, supports complex geometries | Higher cost, longer lead times, limited part size for very large components | Precision components, aerospace, medical, intricate parts |

| Sand Casting | Lower tooling cost, suitable for large parts, flexible material selection | Lower surface quality, dimensional tolerances not as tight, higher machining allowance | Large structural components, low-to-medium complexity parts |

| Die Casting | High production speed, good surface finish, excellent for thin walls | Limited to non-ferrous metals, high tooling cost, less suitable for large parts | Automotive parts, electronics housings, high-volume production |

| Forging | Superior mechanical properties, high strength and toughness | Limited shape complexity, higher machining requirement, size restrictions | Load-bearing components, shafts, gears, high-strength parts |

| CNC Machining | High precision, tight tolerances, rapid prototyping flexibility | Material waste, slower for complex shapes, cost increases with part size | Prototyping, low-volume production, custom or intricate designs |

Industrial Applications

Investment casting is widely used across multiple industries due to its ability to produce high-precision components with complex geometries and consistent material properties. The following applications illustrate how this process meets the specific demands of different sectors.

1. Aerospace and Defense

- Jet Engine Components: Turbine blades, nozzles, and combustor parts requiring high-temperature superalloys.

- Airframe and Structural Parts: Lightweight, complex parts with strict dimensional tolerances.

- Defense Equipment: Precision metal parts for missiles, guidance systems, and naval applications.

2. Automotive and Transportation

- Engine Components: Turbocharger housings, valve bodies, and intake manifolds.

- Transmission Parts: Gear housings and structural components with complex internal geometries.

- Lightweight Components: Aluminum and steel parts that reduce weight while maintaining strength.

3. Medical Devices

- Surgical Instruments: Stainless steel or cobalt-chrome instruments with precise tolerances.

- Implants: Orthopedic, dental, and spinal implants requiring biocompatible alloys.

- Diagnostic Equipment: Small, intricate components for imaging and laboratory devices.

4. Energy and Power Generation

- Turbine Components: Gas and steam turbine blades made from high-temperature superalloys.

- Pumps and Valves: Critical parts in power plants requiring corrosion and wear resistance.

- Generators and Motors: Precision parts for efficiency and reliability in energy equipment.

5. Oil, Gas, and Heavy Equipment

- Drill and Pump Components: High-strength, wear-resistant parts for drilling and extraction.

- Valves and Fittings: Corrosion-resistant components for harsh oilfield environments.

- Heavy Machinery: Gears, housings, and structural parts requiring both strength and complex geometry.

How to Choose an Investment Casting Supplier

Choosing the right investment casting supplier is essential for ensuring quality, timely delivery, and project success. The following sections break down the critical factors and what to look for in each, providing a clear visual guide for evaluation.

1. Technical Capability and Experience

Focus Areas: Design expertise, alloy knowledge, experience with complex components.

Why It Matters: Ensures parts are manufacturable, accurate, and defect-free.

2. Material and Process Certifications

Focus Areas: Compliance with ASTM/ISO/AS9100/Nadcap, traceability of materials.

Why It Matters: Guarantees material quality, regulatory compliance, and accountability.

3. Production Capacity and Lead Time

Focus Areas: Prototype to medium/large batches, scheduling flexibility, scalability.

Why It Matters: Supports timely delivery without sacrificing quality.

4. Engineering Support and Cost Efficiency

Focus Areas: Design assistance, cost optimization, proactive problem solving.

Why It Matters: Reduces project risk, improves manufacturability, and balances cost.

Conclusion

The investment casting process produces complex metal components with high dimensional accuracy and smooth surface finishes by using wax patterns, ceramic molds, and controlled metal pouring. It accommodates a wide range of metals—including stainless steel, alloy steel, aluminum, copper-based alloys, superalloys, and specialty alloys—enabling intricate geometries, thin walls, and integrated structures that are difficult to achieve with other manufacturing methods. The process offers near-net-shape production, reproducibility, reduced material waste, and flexibility across multiple alloys, though it involves higher costs, longer lead times, and practical size limitations for very large parts.

Investment casting is widely applied across industries such as aerospace, defense, automotive, medical devices, energy, and heavy equipment. Key considerations in supplier selection include technical capability, material and process certifications, production capacity, lead time, and engineering support. By combining precise geometry, material versatility, and controlled metallurgical properties, investment casting ensures reliable performance and consistent quality for complex, high-precision components.

-

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World -

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China -

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

-

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China -

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World -

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China -

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China