Heavy Equipment Work Light Housing Development Case

Project Brief

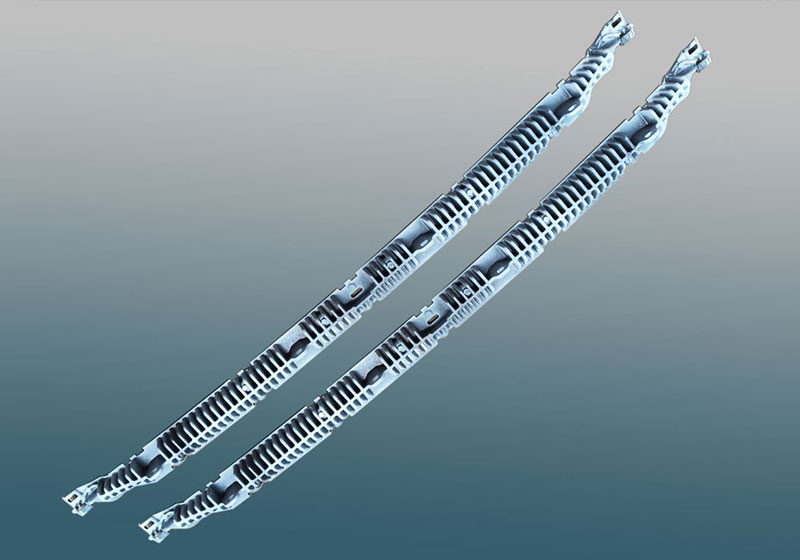

This is a custom-designed LED work light housing for heavy-duty equipment, such as trucks and bulldozers. The LED housing not only protects the internal LED components but also serves multiple functions including thermal management and mechanical support.

1. Product Standards & Requirements: Material: ALSI12; All dimensions must meet drawing tolerances (Grade ISO 2768-mK); Salt spray test: 600 hours; PPAP approval must be completed and passed before formal mass production.

2. Product Challenges: The heat sink surface of this heavy equipment work light housing is covered with cooling fins of varying depths, with a fin width of 2.2mm. The geometry leads to localized areas prone to carbon buildup and damages the mold core, placing high demands on die-casting parameters. The square hole design requires extremely high precision (3.6±0.1) and consistency.

Risk Keywords: Casting control difficulty, Blank precision, Carbon buildup risk, Special holes, Corrosion resistance

The overall project presented a significant challenge, particularly testing our capabilities in mold design and quality control.

Development Process

For this project, we formed a development team including mold designers, casting engineers, machining engineers, measurement engineers, quality engineers, and sales. The team applied the internationally advanced Advanced Product Quality Planning (APQP) methodology, entering a comprehensive product development process focused on quality.

The first step involved DFM analysis to thoroughly understand and optimize certain product details for enhanced manufacturability, establishing mutually agreed-upon technical specifications and quality standards with the customer.

Considering the application environment and performance requirements, the housing material was confirmed as ALSI12. Based on the material properties and the core design elements of the product's typical heat dissipation fins, the process route of high-pressure die casting (HPDC) + CNC precision machining was ultimately determined, balancing technical feasibility, quality stability, and cost control.

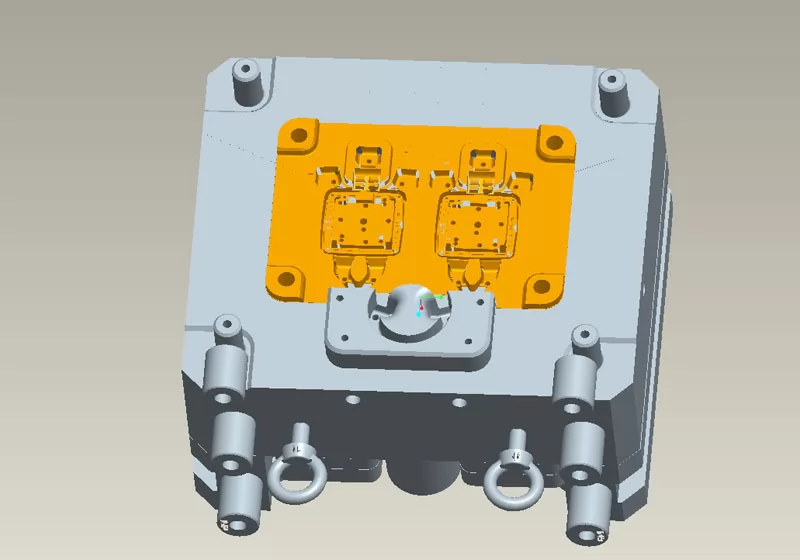

Subsequently, leveraging years of mold development experience, technical engineers finalized a 2-cavity mold design. They performed mold simulation and mold flow analysis to predict and optimize various challenges and process parameters, and established preliminary Process Flow Charts and Control Plans.

Finally, the plan was gradually validated, and issues were identified and resolved in the subsequent practical stages.

Practice Validation & Optimization

Starting from mold manufacturing, the project entered the actual production phase. Our company proceeded according to the initial Process Flow Chart, established the Control Plan, and applied FMEA tools for risk analysis and assessment of various potential failure modes. The main key issues encountered during the actual manufacturing process were as follows:

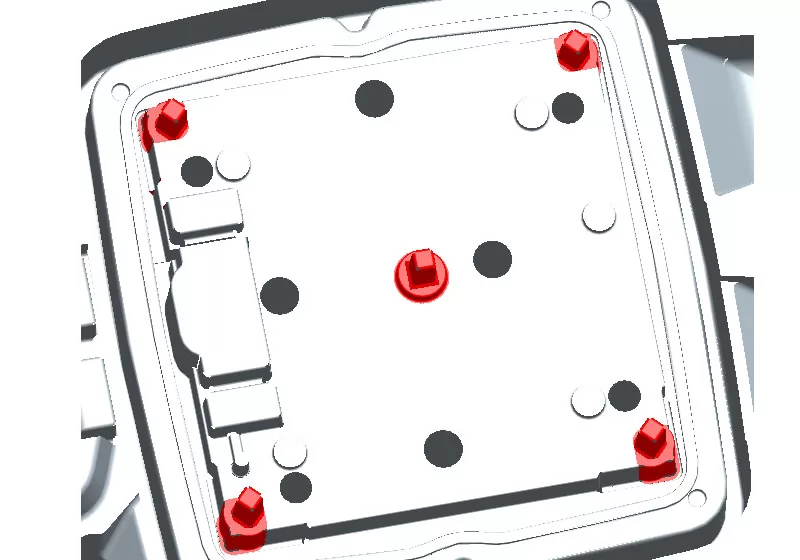

A. Replaceable Pin Design Optimizes Square Hole Challenge

This Heavy Equipment Work Light housing aluminum casting features a distinctive square hole design, which presented the following challenges:

1. Square holes demand higher dimensional accuracy and consistency.

2. While an integrated design suits square holes, pins within a solid mold core can bend or damage during prolonged die-casting, leading to damage of the entire core. This approach is less economical and maintainable.

To address this, the development team decided to implement an insert-based, replaceable pin design. With this design, if a pin is damaged, it can simply be extracted and replaced without scrapping the entire mold core, significantly improving cost-effectiveness.

In subsequent production, this replaceable pin design proved highly effective. Furthermore, to ensure pin dimensional consistency, we adopted a strategy of replacing pins in sets, guaranteeing both replacement and dimensional uniformity.

B. Added Mold Undercut Optimizes Sticking Issue

During sampling, inspection engineers found sticking on some castings, all located above the parting line, with a statistical problem rate reaching 32%.

After review, the technical team decided to add an undercut design at the corresponding position on the upper mold. Practice proved this design very effective, eliminating the sticking issue entirely.

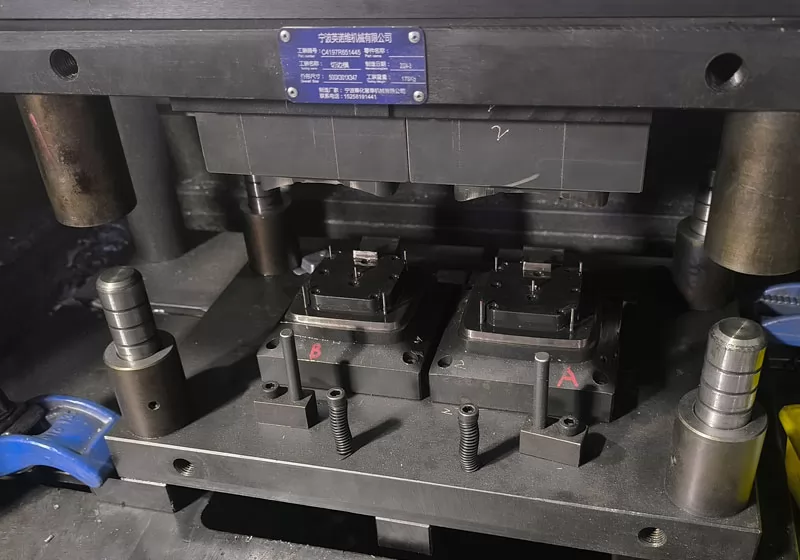

C. Developed Dedicated Trimming Die to Improve Efficiency

Product development involves not only quality control but also focus on production efficiency and cost control. For this work light, the team explored efficiency improvements across various aspects, the most significant being the development of a dedicated trimming die. This die allows for one-time removal of gates and burrs, reducing subsequent processing steps and greatly enhancing production efficiency.

D. Exceeded Standard Salt Spray Test Ensures Corrosion Resistance Requirement

Heavy equipment work light housing are typically used in outdoor construction sites and similar environments, leading to strict customer requirements for corrosion resistance. Besides the inherent corrosion resistance of the material, the external surface also undergoes Powder Coating. To better guarantee performance, the customer specified a salt spray test requirement of 600 hours. We actually conducted the test for over 720 hours, and the practical conclusion was that no red rust appeared, verifying that the product quality exceeded technical specifications.

Quality Control

The entire development process was a systematic procedure of identifying and controlling quality risks while continuously optimizing the process. The heavy equipment work light housing project team leveraged rich experience and solid technology to conduct technical reviews and repeated verification at every process step, systematically identifying and tackling potential risk points. The team strictly adhered to the IATF 16949 quality system, implementing the full APQP process requirements to achieve full-process quality control. Throughout the process, various standardized documents and practices such as FMEA, SPC, MSA, and Control Plans were established and executed to prevent potential process risks, quality risks, and control quality variation. Finally, PPAP documentation was established and approved by the customer, laying a solid foundation for formal mass production.

The process included first-article inspection, in-process inspection, and outgoing inspection, establishing complete inspection data retention to ensure all quality data is traceable and verifiable.

Results and Evaluation

Finished Product Metrics:

1. Dimensional Accuracy: All met according to ISO 2768-mK requirements.

2. Surface Quality: Free from any visible defects; met standards.

3. Assembly Quality: Customer satisfied.

5. PPAP completed and approved by the customer.

The development of this aluminum die-cast Heavy Equipment component by Innovaw, with its relatively high technical difficulty and stringent comprehensive performance requirements, served as a test of the manufacturer's overall capabilities. Relying on profound expertise in high-pressure die casting, precision CNC machining capabilities, and an excellent quality management system consistently implemented throughout the process, we successfully overcame the challenges and delivered a high-quality product that met and even exceeded customer expectations. This fully demonstrates our casting development team's professional capability for systematic problem analysis and rapid closed-loop improvement in developing complex structural components.

Production Process

Mould making→Melting→High Pressure Die Casting→Cutting the sprue and riser→Deburring→Machining→Powder Coating→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.