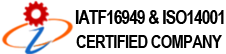

China Aluminum Gravity Casting Supplier

As a leading China Aluminum Gravity Casting Supplier, we specialize in high-quality aluminum gravity casting, offering fully customized solutions for global industries. Our advanced facilities integrate mold design, gravity casting, CNC machining, and surface finishing to produce components that meet stringent performance requirements.

Custom Services by China Aluminum Gravity Casting Supplier

Our China Aluminum Gravity Casting Supplier operates gravity casting lines for aluminum alloys such as ADC12, A380, and 6061. We ensure precise metal flow, dimensional stability, and low porosity for both small and large components. Custom finishes such as powder coating, anodizing, and polishing are available to match functional and aesthetic requirements.

Full Process Control for Customized Components

From prototyping to mass production, the China Aluminum Gravity Casting Supplier manages every stage of the workflow. Our engineers collaborate closely with clients to optimize mold design, adjust casting parameters, and produce custom parts that fulfill exact mechanical and surface specifications. Quality inspection and testing ensure each component meets international standards.

Global Reach and Reliable Delivery

As a China aluminum gravity casting company and supplier, the China Aluminum Gravity Casting Supplier serves clients across Europe, North America, and Asia. With full export support and custom logistics solutions, we provide stable delivery of precision gravity castings for critical applications.

Automotive Heat Sink Housing Castings

This was a custom-designed automotive heat sink shell tasked with multiple functions, including component protection, interfacing with different structures, as well as providing support and heat dissipation.

Automotive Heat Sink Housing Castings

This was a custom-designed automotive heat sink shell tasked with multiple functions, including component protection, interfacing with different structures, as well as providing support and heat dissipation.

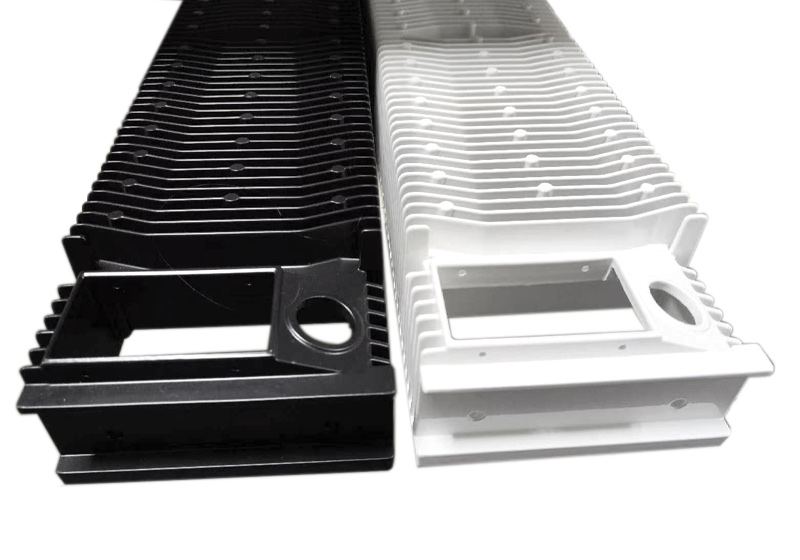

Automotive Electronic Heat Sink

This is a customized aluminum alloy heat sink for an important part of the car, presumably mainly used for automotive control circuits for heat dissipation and sealing function. This auto parts heat sink shell aluminum casting using aluminum high-pressure die casting one-piece molding process, the finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection features, but also easy to install and maintain.

Automotive Electronic Heat Sink

This is a customized aluminum alloy heat sink for an important part of the car, presumably mainly used for automotive control circuits for heat dissipation and sealing function. This auto parts heat sink shell aluminum casting using aluminum high-pressure die casting one-piece molding process, the finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection features, but also easy to install and maintain.

Motor Stator Tube Castings

This is a custom-designed motor stator tube casting. The product features a hollow cylindrical structure with double-layer concentric coaxial sleeves, presenting complex internal and external geometries.

Motor Stator Tube Castings

This is a custom-designed motor stator tube casting. The product features a hollow cylindrical structure with double-layer concentric coaxial sleeves, presenting complex internal and external geometries.

Ship LED Work Light Housing

This is a customized aluminum alloy heat sink housing for LED lights, which is mainly used for lighting LED lights on ships and yachts. This LED light aluminum alloy heat dissipation shell aluminum casting adopts aluminum high-pressure die-casting one-piece molding and cnc machining process.

Ship LED Work Light Housing

This is a customized aluminum alloy heat sink housing for LED lights, which is mainly used for lighting LED lights on ships and yachts. This LED light aluminum alloy heat dissipation shell aluminum casting adopts aluminum high-pressure die-casting one-piece molding and cnc machining process.

Marine Stabilizer Housing

This is a customized large aluminum alloy casting, which is presumed to be used in the structural housing of dynamic balance system on ships and yachts, or power transmission housing such as gearbox. This aluminum casting is made by aluminum low pressure die casting and cnc machining process.

Marine Stabilizer Housing

This is a customized large aluminum alloy casting, which is presumed to be used in the structural housing of dynamic balance system on ships and yachts, or power transmission housing such as gearbox. This aluminum casting is made by aluminum low pressure die casting and cnc machining process.

Construction Machinery Work Light Housing

This is a customized LED work light housing aluminum casting, is a specific engineering equipment led light core components. led light shell not only protects the internal led light components, but also bear the thermal management, mechanical support and other multiple functions. This engineering machinery LED light housing aluminum casting using aluminum high-pressure die casting one-piece molding plus cnc machining process, the finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection features, but also easy to install and maintain.

Construction Machinery Work Light Housing

This is a customized LED work light housing aluminum casting, is a specific engineering equipment led light core components. led light shell not only protects the internal led light components, but also bear the thermal management, mechanical support and other multiple functions. This engineering machinery LED light housing aluminum casting using aluminum high-pressure die casting one-piece molding plus cnc machining process, the finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection features, but also easy to install and maintain.

Heavy Equipment Work Light Housing

This is a custom-designed LED work light housing for heavy-duty equipment, such as trucks and bulldozers. The LED housing not only protects the internal LED components but also serves multiple functions including thermal management and mechanical support.

Heavy Equipment Work Light Housing

This is a custom-designed LED work light housing for heavy-duty equipment, such as trucks and bulldozers. The LED housing not only protects the internal LED components but also serves multiple functions including thermal management and mechanical support.

Gas Meter Base castings

This is a custom-made gas meter housing base, serving as the core component of the gas meter. Its primary functions include connecting the gas inlet and outlet ports, supporting and sealing the internal mechanism, and ensuring the smooth operation of critical internal parts.

Gas Meter Base castings

This is a custom-made gas meter housing base, serving as the core component of the gas meter. Its primary functions include connecting the gas inlet and outlet ports, supporting and sealing the internal mechanism, and ensuring the smooth operation of critical internal parts.

Gas Meter Valve Housing Casting

Customers come to the customized gas meter accessories aluminum castings, presumably a specific gas meter valve body housing. The gas meter valve housing not only protects the internal components, but also assumes multiple functions such as connecting the inlet and outlet ports and supporting the mechanical seals.

Gas Meter Valve Housing Casting

Customers come to the customized gas meter accessories aluminum castings, presumably a specific gas meter valve body housing. The gas meter valve housing not only protects the internal components, but also assumes multiple functions such as connecting the inlet and outlet ports and supporting the mechanical seals.

Water Heater Part Housing

This is a customized water heater parts aluminum castings, the material is aluminum alloy, presumably for the water heater circulating pump motor end cover. This water heater fittings aluminum castings using aluminum high-pressure die-casting one-piece molding and cnc machining process, the finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection features, but also easy to install and maintain.

Water Heater Part Housing

This is a customized water heater parts aluminum castings, the material is aluminum alloy, presumably for the water heater circulating pump motor end cover. This water heater fittings aluminum castings using aluminum high-pressure die-casting one-piece molding and cnc machining process, the finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection features, but also easy to install and maintain.

Dental Chair Part Casting

This is a customized aluminum casting, which is an important part of a dental chair. This dental chair aluminum casting adopts aluminum high-pressure die-casting one-piece molding plus cnc machining process, the finished product not only has excellent mechanical properties and good processing accuracy, but also has good lightweight, corrosion resistance, compact design and easy to install and maintain.

Dental Chair Part Casting

This is a customized aluminum casting, which is an important part of a dental chair. This dental chair aluminum casting adopts aluminum high-pressure die-casting one-piece molding plus cnc machining process, the finished product not only has excellent mechanical properties and good processing accuracy, but also has good lightweight, corrosion resistance, compact design and easy to install and maintain.