- Mold Preparation: Molds are cleaned and coated with a releasing agent or refractory material to prevent sticking. Sand molds may be compacted and reinforced for stability.

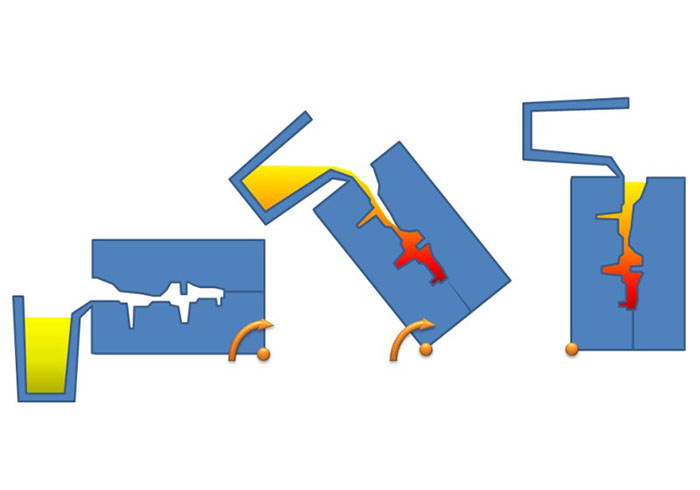

- Pouring: Molten metal is carefully poured into the mold from a ladle, ensuring a steady and controlled flow.

- Solidification: The metal cools and solidifies in the mold. Cooling times depend on the mold material (sand molds cool slower than metal molds).

- Demolding: After the metal solidifies, the casting is removed from the mold. For sand molds, the mold is typically broken apart.

- Finishing: Excess material like sprues, runners, and risers is trimmed. Additional machining or surface finishing may be applied as needed.

Gravity Casting

Aluminum Gravity casting is a metal casting process in which molten metal is poured into a mold under the influence of gravity alone, without the use of additional pressure or vacuum. It is one of the simplest and most cost-effective casting methods, commonly used for producing medium-to-large parts with a wide range of alloys.

Advantages of aluminum gravity casting:

- Wide Material Compatibility: Suitable for a variety of metals and alloys.

- Versatility: Can handle small to very large components.

- Good Dimensional Accuracy: Especially when using permanent molds.

- Good Dimensional Accuracy: Simple equipment and minimal operational costs.

- Ease of Customization: Sand molds enable complex shapes with internal cavities.

_1750747237_WNo_1000d800.jpg)

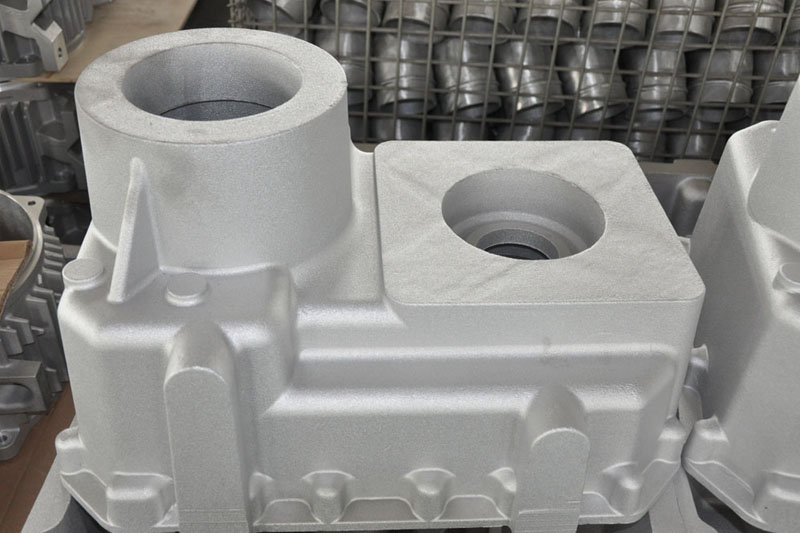

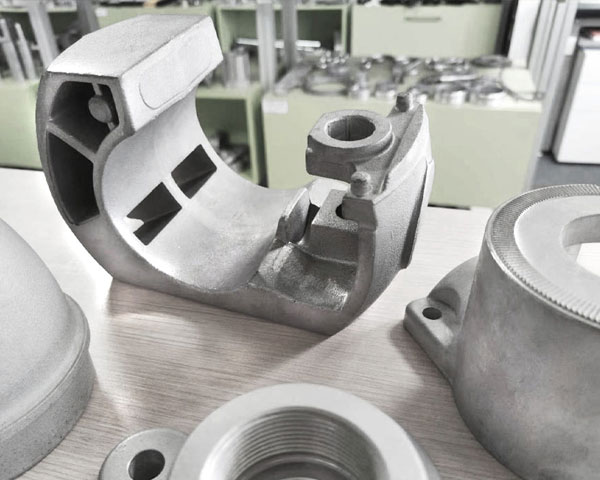

Aluminum Gravity Casting in Innovaw

Innovaw's gravity casting production line has 12 advanced tilting gravity casting machines, including sand mixers, molding machines, pouring machines, and post-processing equipment. Our gravity die casting products cover automotive parts, medical devices, aerospace, lighting equipment, energy equipment components, marine vessels, industrial equipment, kitchen appliances and other components. Our products range in size from 100x100mm to 600x600mm and in weight from 100g to 50Kg, with a daily production capacity of 3-4 tons.

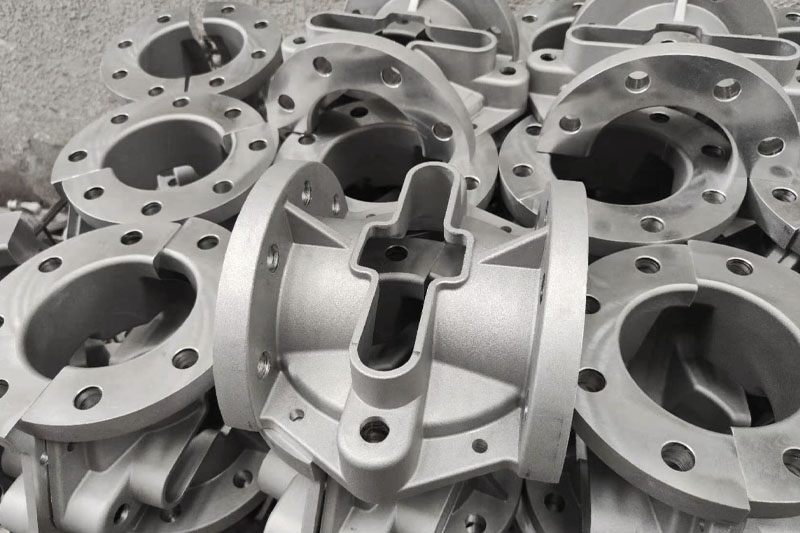

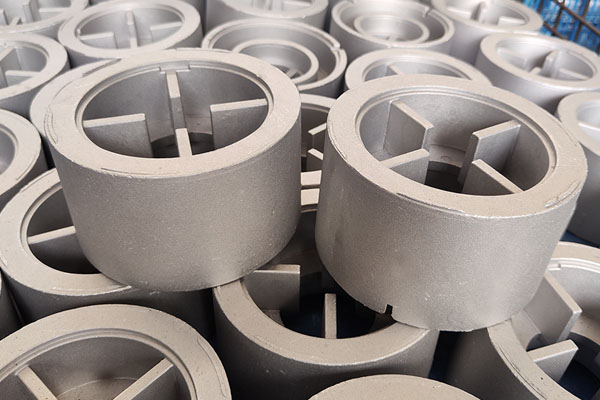

Products on Aluminum Gravity Casting Lines

Industrial Equipment Drive Systems

Energy industry

Oil, natural gas

Aerospace

Chemical industry

Industrial equipment

Material Scope

Innovaw's foundry complies with ASTM, JIS, DIN, ENAC, ISO, and GB material specifications. Common aluminum alloy grades suitable for gravity casting processes are as follows:

- Aluminum Alloys

ASTM-A319, A413, A355, A356, A357

JIS-AC2B, AC4D, AC4C, AC3A, AC4A

DIN-AlSi7cu4, AlSi5cu1Mg, AlSi7Mg, AlSi12, AlSi9Mg, AlSi12Cu2Mg1, AlSi6Cu4

ENAC-45000, 45300, 42100, 44100, 43300

How Aluminum Gravity Casting Works

Aluminum gravity casting relies on natural gravity to make molten aluminum flow into the mold cavity, cooling and solidifying to form castings. It does not require high pressure to push the metal flow like die casting, so the process is relatively gentle and suitable for some aluminum alloy parts that do not require high pressure injection.

Why Innovaw Aluminium Gravity Casting

Innovaw's primary mission is to meet customer expectations in quality, delivery, and performance. Our aluminum gravity casting process exceeds our customers' expectations in terms of production capacity, technical support, quality control and service.

Production Capability

After more than 20 years of development, Innovaw has complete productivity in aluminum gravity casting segment with standardized plant and advanced machines. The daily capacity of aluminum gravity casting is 3-4T.

We have a perfect production management process, a large number of highly qualified managers and workers. Every day, more than 20 production management experts and hundreds of workers provide professional production services to our customers.

From mold development to PPAP approval, serialization, GDC, processing and surface treatment production, the whole process provides one-stop service to create value for customers.

Technical Capability

We have a technical team of more than 20 engineers and industry experts to provide comprehensive support.

Relying on our rich experience, we provide one-stop service from DFM analysis, 3D mold design, mold flow analysis to rapid prototyping, helping our customers quickly realize high-quality products from drawings.

We specialize in providing effective engineering solutions to help customers reduce cost and improve quality.

We are experienced in the design and production of complex geometric products, and are especially good at using sand cores to realize complex mold cavity structures.

Through advanced mold filling technology and GDC process, we can effectively control metal flow, reduce turbulence and improve casting quality.

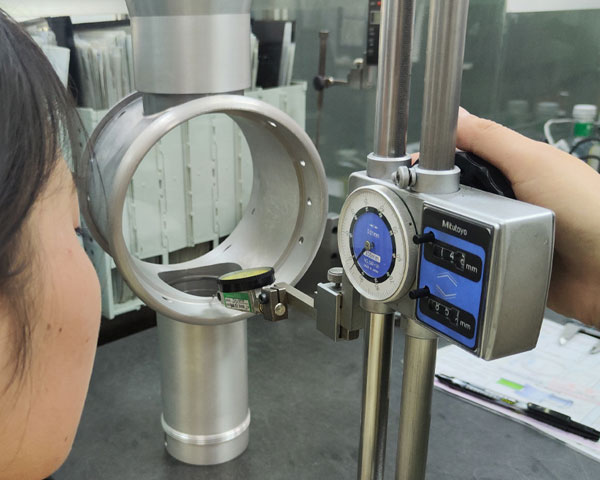

Quality Control

Our gravity casting products take IATF 16949 quality management system as the implementation standard.

We utilize core tools such as APQP, FMEA, PPAP, MSA, SPC, etc. to achieve production process control.

Process audits are regularly conducted through VDA6.3 and product audits are regularly conducted through VDA6.5.

Regularly use 8D analysis and report to deal with customer complaints and solve problems from the root cause.

All products need to pass the whole process inspection, including Spectrometer, 3D scan, X-ray, ZEISS CMM, etc. from the first article to final inspection.

Gravity Casting FAQs

Q1. What metal materials can gravity casting be applied to?

Gravity casting can be applied to various metals including aluminum, zinc, copper, and their alloys.

Q2. Does gravity casting deliver faster than other casting processes?

Gravity casting often has faster delivery times compared to some other casting processes due to simpler tooling and shorter production cycles.

Q3. How do I know if my parts require gravity casting?

You should consider gravity casting if your part requires good mechanical properties, moderate complexity, and cost-effective production for medium to high volumes.

Q4. In which industries is gravity casting mainly used?

Gravity casting is widely used in industries such as automotive, aerospace, machinery, and plumbing for producing high-quality metal components.

Q5. What is the difference between gravity casting and high pressure die casting?

Gravity casting relies on molten metal poured by gravity into molds, while high-pressure die casting forces metal under high pressure, enabling thinner walls and faster cycle times.

Q6. Why choose gravity casting to manufacture your products?

Among the many casting processes, gravity casting, as an efficient and controllable metal forming technology, stands out in many manufacturing scenarios with its unique process characteristics.

1. When to choose Gravity Casting

- Medium-complexity geometric structures: Such as shells, brackets, covers, etc.

- High requirements for mechanical properties: Such as the need for load-bearing structure, pressure resistance, and impact resistance

- Medium-to-high standards for product surface quality and dimensional accuracy

- The production batch is medium-sized (hundreds to thousands of pieces)

- High requirements for material density and casting organization: Such as good air tightness or machinability

Typical industries include: automotive parts, industrial equipment housings, motor housings, wind power/photovoltaic brackets, high-end home appliance structural parts, etc.

2. Key advantages of Gravity Casting

- Good mechanical properties: Due to the fast cooling speed, fine grains, dense casting structure and high strength, it is particularly suitable for parts with structural strength requirements

- Higher dimensional accuracy and surface quality: The metal mold has high molding accuracy and the surface finish is better than traditional sand casting, which reduces the amount of subsequent processing

- Moderate mold cost and long service life: Suitable for medium-volume production, the mold can be used repeatedly, saving long-term costs

- Better consistency and controllability: Compared with manual sand molds, gravity casting has stable process parameters, stronger product consistency, and is conducive to quality control

If you are looking for an aluminum alloy casting solution that takes into account performance, cost and efficiency, gravity casting is undoubtedly an ideal choice to balance all factors. It not only meets the basic requirements of most industrial products for performance and appearance, but also has good economy and sustainability. Reliable, efficient and trustworthy is a solid guarantee for your product quality and market competitiveness.