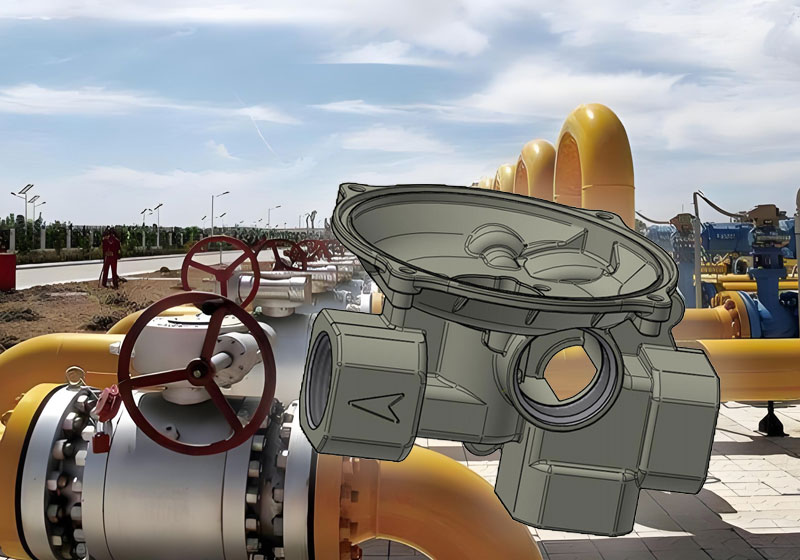

Gas Meter Valve Housing Development Case

Project Description

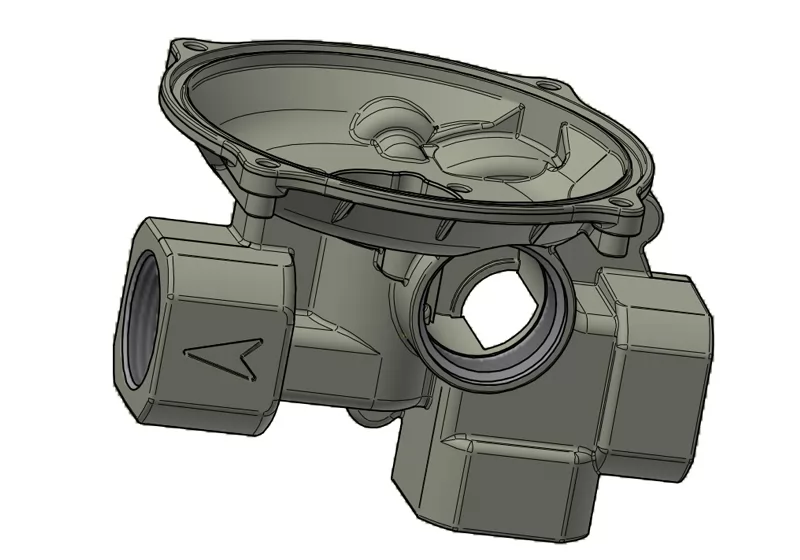

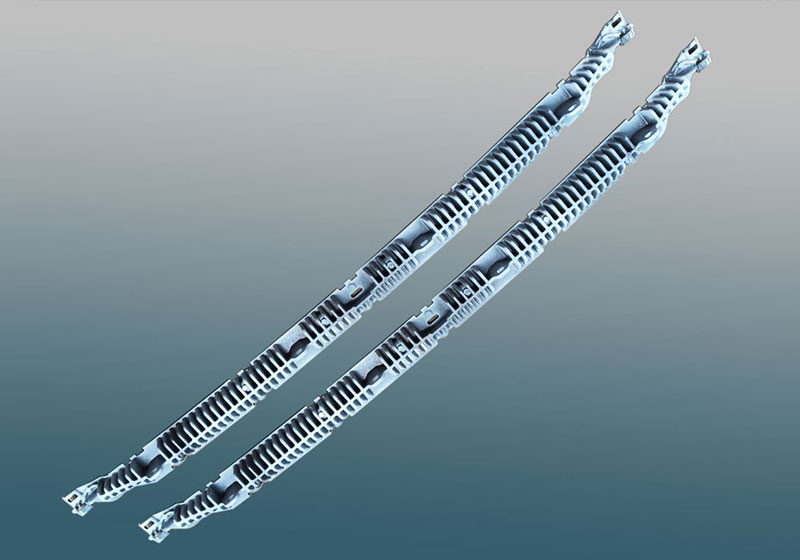

This is a customized gas meter valve housing, whose main function is to connect inlet and outlet ports, support and seal the internal mechanism.

1. Product Standards and Requirements:Material ADC12 aluminum; dimensional tolerance grade ISO 2768-mk; minimum tolerance 0.05; minimum flatness 0.1; no visible surface defects; surface roughness Ra6.3µm; surface powder coating 80-120μm; neutral salt spray test 1000H. PPAP approval must be completed and passed before mass production.

2. Product Challenges:Complex structure, 4-slider mold design; uneven thickness prone to porosity; high corrosion resistance requirement.

Risk Keywords:complex structure, high precision, porosity, assembly accuracy, zero surface defect

The overall project has a certain level of difficulty, particularly testing our mold design capability and quality control capability.

Development Process

For this project, we formed a development team consisting of mold designers, casting engineers, machining engineers, quality engineers, and sales staff. Following the core methodology of APQP (Advanced Product Quality Planning) under the requirements of the international IATF 16949 standard, we carried out a comprehensive product development process centered on quality.

We first conducted DFM analysis, optimizing certain structural details to improve manufacturability, and established mutually agreed technical specifications and quality standards with the customer.

Considering the application environment and performance requirements of this component housing, ACD-12 was selected as the housing material. Based on the material properties and the core design elements of this product, and from the perspectives of technical feasibility, quality stability, and cost control, we finally determined the process route: high-pressure die casting + CNC precision machining, using a 280T high-pressure die casting machine.

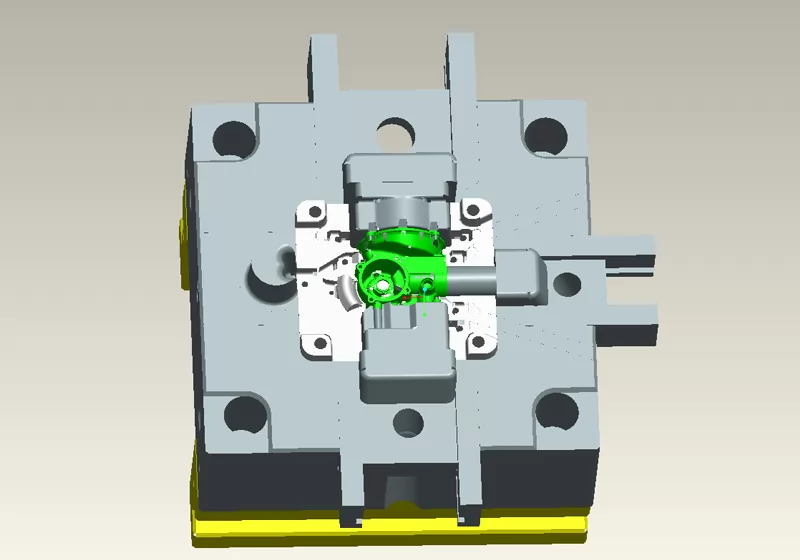

Subsequently, technical engineers carried out mold simulation and mold flow analysis to predict and optimize difficulties and process parameters, and established a preliminary process flow chart and process control plan.

Finally, during the subsequent practical procedures, the solution was gradually verified, and problems were identified and resolved.

Practical Verification and Optimization

Starting from mold manufacturing, the project entered the actual manufacturing phase. Our company proceeded according to the initial Process Flow Chart, established the Control Plan, and applied FMEA tools for risk analysis and assessment of various potential failure modes. The main key issues encountered during the actual manufacturing process were as follows:

A. Solving Porosity Problem

By carefully analyzing the customer’s drawing, it was evident that the product had a complex structure, deep cavities, and large wall thickness variations, leading to potential risks of porosity and shrinkage defects. In the first mold trial stage, quality engineers performed X-ray inspection on the same batch of castings, and porosity was indeed found in specific product areas, with a defect rate of 60%. To address this challenge, we organized a special review, analyzed defect distribution patterns, and combined our years of multi-slider mold development experience to formulate targeted design optimization strategies. The final solution was determined as follows:

1. Strengthen auxiliary venting design on both sides of the mold and optimize gating design.

2. Adjust and precisely control melting and high-pressure die casting parameters, with particular focus on intensification pressure and injection speed. Apply SPC (Statistical Process Control) to key parameter data, collect batch data into the system, analyze with SPC tools, and carry out continuous monitoring and improvement.

After three consecutive rounds of validation trials, 150 additional samples were produced. X-ray inspection confirmed a 100% pass rate, successfully solving the porosity issue.

B. Customized Pressure Test Fixture for Sealing Verification

As a gas valve body aluminum casting, sealing performance is critical. Therefore, strict requirements were imposed on porosity and dimensional accuracy. In addition to X-ray inspection for porosity, we customized a pressure test fixture specifically for this product’s sealing performance verification.

C. Challenge of 1000H Salt Spray Test

For this project, the customer required extremely high corrosion resistance, with a neutral salt spray test of up to 1000 hours. From the selection of the high-pressure die casting process, to resolving porosity problems, and to precision control at subsequent process stages, all efforts were made to achieve corrosion resistance. Finally, at the critical surface treatment stage, we adopted a process of oxidation followed by powder coating. Through close cooperation across all stages, the final 1000-hour salt spray test proved the effectiveness of the preceding work.

Quality Control

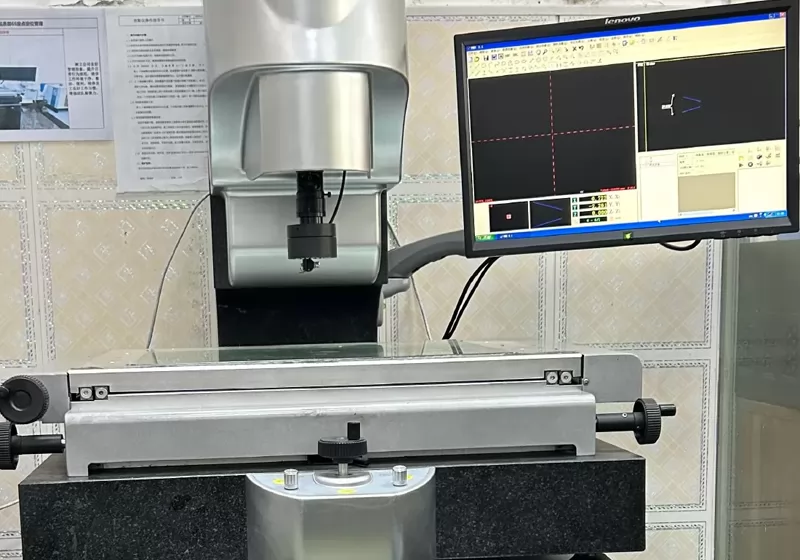

The entire development process was a systematic process of identifying and controlling quality risks and continuously optimizing processes. The gas meter valve body project team, with its rich experience and solid technical expertise, carried out technical reviews and repeated verification at every process stage, systematically identifying and overcoming potential risks.

Quality engineers strictly followed the IATF 16949 quality system and implemented the full APQP process requirements to achieve complete quality control. During the process, FMEA, SPC, MSA, and process control plans were established and executed to prevent potential process risks and quality risks, and to control quality variation. Finally, PPAP documents were completed and approved by the customer, laying a solid foundation for mass production.

Inspections were arranged throughout the process: first article inspection, in-process inspection, and final inspection, with complete inspection data records established to ensure traceability and verification of all quality data.

Results and Evaluation

Final Product Indicators:

1. Finished product tolerance grade ISO 2768-mk; minimum tolerance 0.05; minimum flatness 0.1 – all meeting standard requirements.

2. Sealing performance passed test.

3. Corrosion resistance test: 1000-hour salt spray, passed.

3. PPAP completed and approved by customer.

The development of this gas meter valve body aluminum casting by Innovaw, with its high technical difficulty and strict comprehensive performance requirements, served as a test of the manufacturer’s overall capability. Through our solid expertise in high-pressure die casting, precision CNC machining, and consistent quality management system, we successfully overcame challenges and delivered a high-quality product that met and even exceeded customer expectations. This fully demonstrated our casting development team’s professional capability in systematic problem analysis and rapid closed-loop improvement for complex structural parts.

Production Process

Mould making→Melting→High Pressure Die Casting→Cutting the sprue and riser→Polishing→Deburring→Shot Blasting→Machining→Powder coating→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.