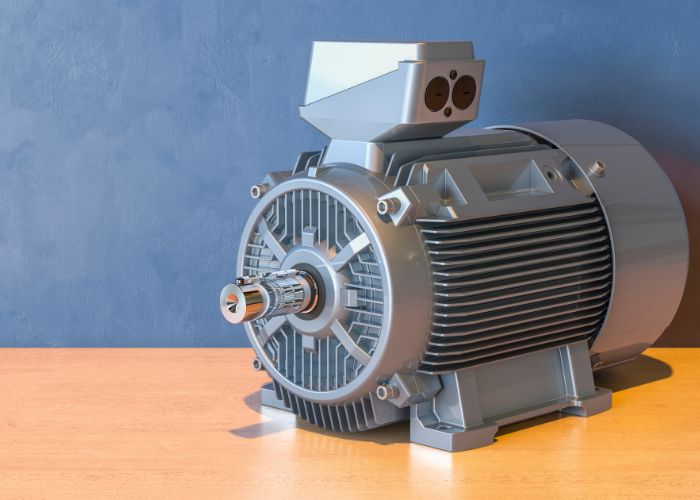

Motor Stator Tube Castings

This is a custom-designed motor stator tube casting. The product features a hollow cylindrical structure with double-layer concentric coaxial sleeves, presenting complex internal and external geometries.

Electric motor castings play a crucial role in ensuring the stability, thermal balance, and long-term reliability of modern motor systems. Through advanced aluminum die casting and precision manufacturing, China manufacturers can produce custom stator tube castings and motor end cover castings with excellent dimensional consistency, high structural rigidity, and optimized heat transfer—features essential for efficient motor operation and extended service life.

Whether applied in industrial machinery, automotive motors, home appliances, or energy-efficient equipment, aluminum motor castings provide durable protection for internal coils and magnetic components. Their lightweight design, corrosion resistance, and strong mechanical performance help motors maintain smooth operation even under continuous load, vibration, or temperature fluctuations.

With refined mold engineering, simulation-driven casting optimization, and strict quality management, modern electric motor castings offer dependable performance across diverse applications. These high-precision components allow global motor manufacturers to enhance motor efficiency, reduce noise, and achieve stable, long-term production with reliable casting quality.

As electric motors continue to advance toward higher efficiency, compact structures, and improved heat management, aluminum castings have become essential to achieving stable performance and long service life. In China’s manufacturing industry, precision die casting and gravity casting are widely used to produce motor stator tube castings and motor end cover castings with excellent strength, accurate geometry, and dependable thermal conductivity.

High-quality electric motor castings are critical for supporting internal magnetic assemblies, protecting windings, and maintaining consistent operating temperature. From industrial motors and automation equipment to EV drive units and household appliances, these castings help reduce vibration, improve heat dissipation, and ensure long-term reliability under demanding working environments.

Looking for custom electric motor aluminum castings?

As a professional China manufacturer, Innovaw offers custom aluminum die casting, gravity casting, and CNC machining tailored for electric motor components. With advanced engineering capabilities and strict quality control, we manufacture durable stator tube castings and end cover castings that meet tight tolerances, corrosion-resistance requirements, and thermal performance needs for global motor brands.

From prototype development to stable mass production, our team provides full support to ensure your electric motor castings deliver consistent performance and long-term reliability.

Request a free quote today and work with a trusted custom electric motor casting manufacturer in China.

This is a custom-designed motor stator tube casting. The product features a hollow cylindrical structure with double-layer concentric coaxial sleeves, presenting complex internal and external geometries.

This is an aluminum casting for a motor end cover, a core component of the motor. The motor end cover not only protects internal components but also serves multiple functions including thermal management and mechanical support.

As a dedicated China-based manufacturer, Innovaw provides complete casting and machining solutions tailored for electric motor components used in industrial, automotive, and automation systems. From early prototyping to large-scale production, our integrated manufacturing workflow ensures stable quality, high efficiency, and reliable engineering support for precision motor castings.

Electric motor aluminum castings must withstand continuous vibration, stable magnetic loading, precise alignment requirements, and efficient heat dissipation. Components such as motor stator tube castings and motor end covers demand exceptional dimensional accuracy, mechanical strength, and porosity control to ensure smooth rotation, reduced noise, and long-term operational stability.

Innovaw enhances casting quality through advanced process control, optimized mold-flow simulation, and high-performance aluminum alloys, reducing internal defects and improving structural density. These improvements make our castings well-suited for motors used in automation equipment, vehicles, HVAC systems, pumps, and other industrial applications requiring robust and reliable performance.

IATF 16949 Certified Manufacturer

Innovaw’s certified quality system ensures consistent accuracy and mechanical stability for electric motor castings. Through controlled production and strict inspections, we minimize porosity, improve durability, and provide reliable performance for industrial and automotive motor applications.

In-House Quality Inspection Lab

Our lab is equipped with CMM, VMS, spectrometers, tensile and hardness testing, X-ray inspection for internal structures, and leak testing systems to ensure precision and performance for motor stator tubes, end covers, and other critical parts.

ISO 14001, ISO 45001, SA8000, ISO/IEC 27001

Innovaw integrates sustainability, worker safety, social responsibility, and information security into every stage of motor casting production, providing dependable support for global manufacturers.

Innovaw specializes in producing precision aluminum castings for electric motor systems across automotive, industrial, and energy applications. Our castings provide excellent dimensional stability, vibration resistance, and thermal performance required for reliable long-term motor operation.

Typical applications include motor stator tube castings for magnetic core support, motor end cover castings for bearing alignment and enclosure sealing, and additional custom housings designed for high-speed motors, pumps, compressors, and automation equipment.

With advanced casting, CNC machining, and surface finishing technologies, we deliver durable components that meet strict performance requirements for electric motor manufacturers worldwide.

Innovaw offers extensive expertise in manufacturing custom motor castings designed for high precision, mechanical strength, and reduced noise and vibration. Our engineering team optimizes each casting for manufacturability, heat dissipation, and structural reliability.

With capabilities in die casting, gravity casting, CNC machining, and advanced surface treatments, we manufacture stator tubes, end covers, and complex housings with exceptional consistency and accuracy. Combined with simulation-driven engineering and certified quality systems, we ensure stable mass production for global partners.

As an ISO 14001, ISO 45001, SA8000, and ISO/IEC 27001 certified manufacturer, Innovaw delivers dependable, sustainable, and high-quality motor casting solutions.

Innovaw provides a range of aluminum alloys suitable for electric motor applications, including A356, A380, ADC12, and high-strength heat-treatable materials. These alloys offer excellent dimensional stability, thermal performance, and structural integrity for stator tubes, end covers, and high-speed motor housings.

To enhance durability and functional performance, we offer precision machining, anodizing, powder coating, electrophoresis, and protective finishes tailored to specific motor environments.

In addition to aluminum casting, Innovaw provides CNC machining, investment casting, sand casting, and gravity casting to support a wide range of motor components. These solutions allow flexibility in geometry, production volume, and performance requirements.

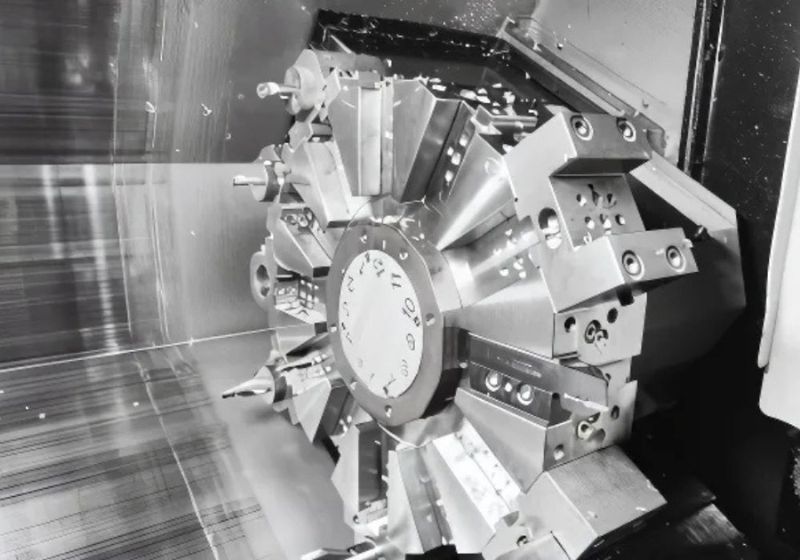

CNC Machining for Motor Components

Innovaw provides precise CNC machining for motor stator tubes, end covers, shaft interfaces, and structural housings. Our machining capabilities ensure accurate tolerances and consistent quality for both small and large production runs.

Investment Casting for Motor Parts

Investment casting is suitable for intricate electric motor components requiring fine detail, smooth surfaces, and high mechanical stability. We manufacture connectors, brackets, and custom housings with reliable precision.

Sand Casting for Motor Components

Sand casting is ideal for larger motor housings, base frames, and thick-wall enclosure parts. Innovaw provides complete sand casting support, including machining and protective finishing.

Gravity Casting for Motor Components

Gravity casting offers excellent material density and strength, making it well-suited for A356 stator housings, end covers, and structural motor elements requiring superior durability and stability.

Innovaw’s electric motor castings and CNC-machined components are supplied to customers in the United States, Canada, Germany, Australia, the United Kingdom, South Africa, and many other global markets. As an ISO9001:2015 certified China manufacturer, we ensure reliability, consistency, and superior performance for every motor component produced.

We specialize in custom aluminum castings designed for stator tubes, end covers, motor housings, and other critical components. With advanced production capabilities and engineering expertise, we deliver durable, precise, and cost-effective solutions for motor manufacturers worldwide.

Contact us today to learn how our casting technology and engineering support can improve the performance and efficiency of your electric motor systems.

Empowering you to fully understand everything about us-start exploring now