Die Casting Tooling

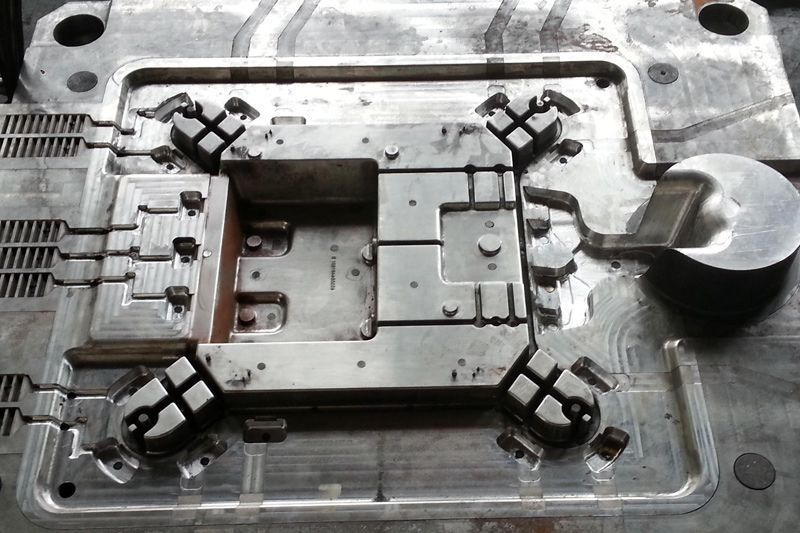

Mold design and manufacturing is one of the key links in the casting production process. Mold design is the process of planning, drawing and determining the mold structure, size, tolerance, cooling system, exhaust system and other technical solutions based on the structure, process requirements and material properties of the casting product. Mold manufacturing is the process of processing the designed mold drawings into mold parts and overall molds that can be used in casting production through CNC machining, milling, turning, EDM, wire cutting, assembly and other process means. The quality of the mold directly affects product quality, production efficiency and manufacturing cost.

Role of die casting tooling:

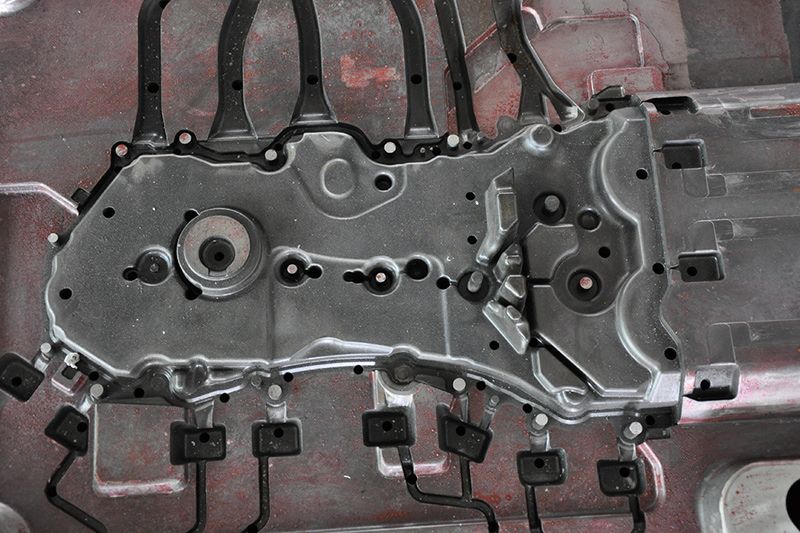

Control casting size, shape and surface quality, reduce casting defects, and improve casting consistency and precision.

Achieve automated, high-speed casting.

Precise design reduces raw material waste, and efficient manufacturing reduces labor and processing costs.

Modular and standardized design improves mold versatility and maintainability.

Die Casting Tooling in Innovaw

In over 20 years of operation, we have built over 10,000 unique molds. All of our die casting and die casting equipment is standardized globally, and we coordinate our tooling resources globally. This means that no matter where your production is located, we can support you from conceptual design, rapid prototyping, mold building, pre-production testing to full production.

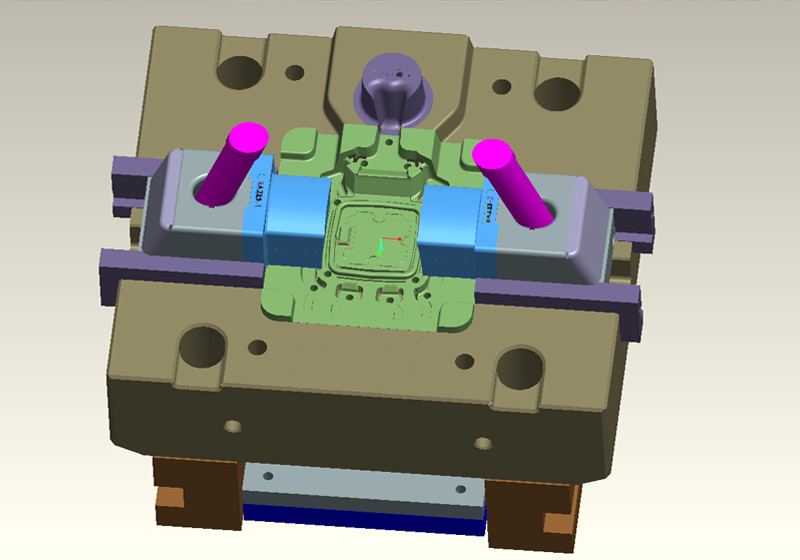

We offer two processes: multi-slide die casting molds and traditional die casting molds.

Multi-slide die casting molds:

Our multi-slide molds allow us to use four (or more) vertical slides in the mold, enabling us to make more complex and precise castings. Has the following advantages:

1. One time molding, eliminating secondary operations such as assembly and machining.

2. Complex geometries and tight tolerances can be realized at a lower overall cost.

3. Minimal variation between parts compared to standard multi-cavity molds.

4. The mold is more compact and less prone to parting line changes, thus reducing its negative impact on the dimensional tolerances of the finished part.

Conventional Die Casting Molds:

Conventional die casting molds are typically either single cavity (producing one part per cycle) or multi-cavity (producing multiple parts per cycle). Our conventional machining technology is designed with only two slides instead of four, providing our customers with higher productivity and lower costs.

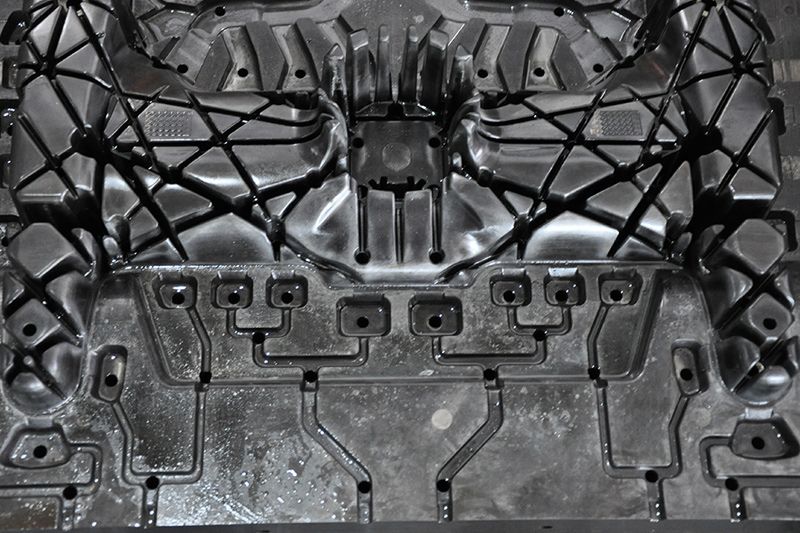

Die Casting Tooling Cases

By choosing INNOVAW as your die casting company, you will get:

1. High-quality molds that can effectively handle high-volume production

2. Focus on mold design and adding multiple features to parts as needed to avoid secondary operations.

3. Careful planning to minimize processing and reduce costs.

4. Predictive wear analysis to extend mold life. Our mold designers can predict which parts of the mold are likely to wear out and insert them as separate pieces of steel.

5. Carefully planned water and cooling lines ensure efficient production.

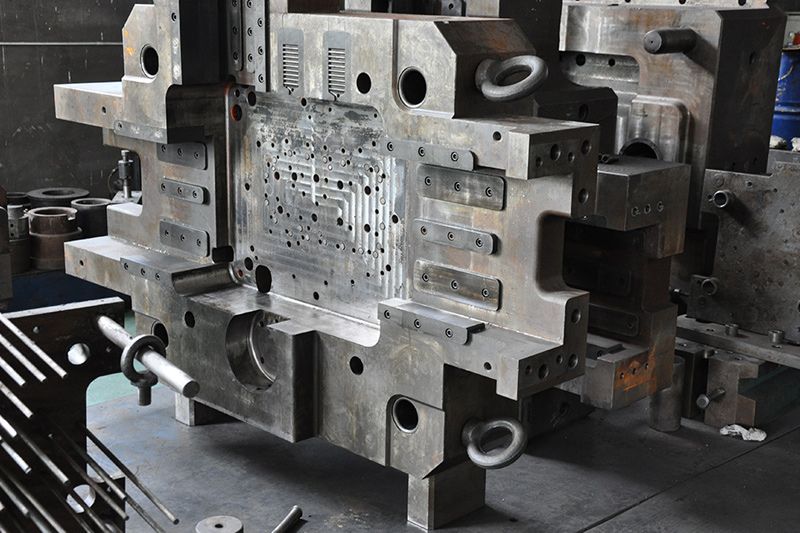

How Die Casting Tooling Design and Manufacturing

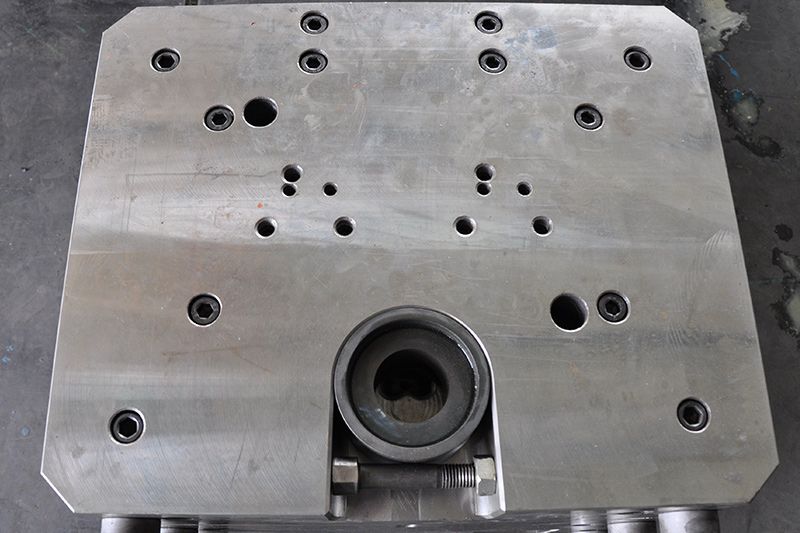

All of our molds begin with a design for manufacturing, and we communicate with our customers to ensure that any defects in the part are checked and corrected before the mold is built. Modifying the features of the mold on the front end will help improve the final part as well as the overall quality of the mold. During this design phase, we can also predict where the mold will wear and design a removable insert for the mold to save time and maintenance costs. We design molds that minimize downtime.

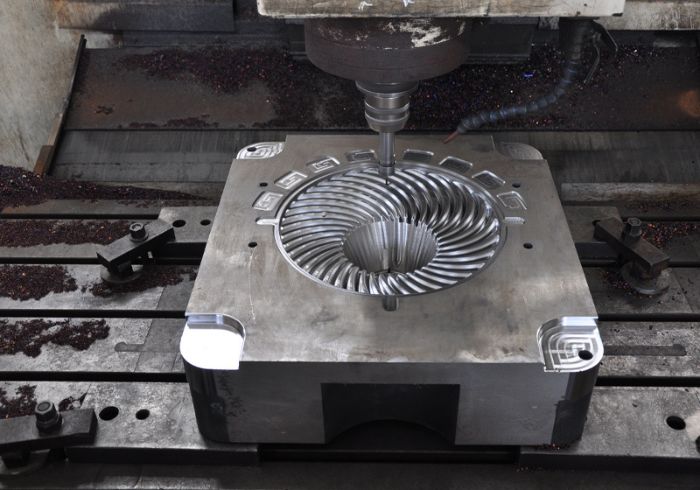

The mold shop is equipped with a group of professional mold design and manufacturing engineers who are proficient in 2D/3D computer software to assist in mold design and manufacturing. The equipment used includes CNC machining centers, EDM, WEDM, universal milling machines, and friction welding equipment.

INNOVAW has advanced engineering skills and works with our customers to design superior products for cost-effective manufacturing. We communicate with our customers on the basis of drawings to discuss further details and gather their requirements. We then use tools such as FEA, mold flow analysis, etc., to clarify and identify critical unresolved issues and address them to ensure the successful production of the part. In addition, a number of prototyping programs support our product development and tooling design processes. INNOVAW can provide rapid prototyping and high pressure die casting molding (HPDC) components in 20 to 35 days, all with engineering support to view the results and make recommendations as necessary.