- Design: The part is designed using CAD software.

- Toolpath Generation: CAM software converts the CAD design into a toolpath, telling the CNC machine how to make the part.

- Programming: The toolpath is translated into G-code, which is the machine's language.

- Machining: The CNC machine follows the programmed instructions, cutting and shaping the material.

- Post-Processing: After machining, parts may need finishing processes like polishing, coating, or assembly.

CNC Machining

CNC Machining (Computer Numerical Control machining) refers to a manufacturing process where pre-programmed computer software controls the movement of machinery tools like drills, mills, lathes, and grinders. The key benefit of CNC machining is that it can produce high-precision parts with complex geometries, which would be difficult or impossible to create with manual tools.

Advantages of CNC Machining:

- High Precision: CNC machines can achieve incredibly tight tolerances, often down to a few microns.

- Repeatability: Once a program is written, the CNC machine can produce identical parts with high consistency.

- Complexity: CNC machines can easily handle intricate designs and geometries, such as curved or 3D shapes, that would be difficult for manual machining.

- Efficiency: Automated machining reduces the time spent per part and minimizes human error.

- Flexibility: CNC machines can be reprogrammed for different tasks, making them versatile for low or high-volume production runs.

_1750750871_WNo_1000d800.jpg)

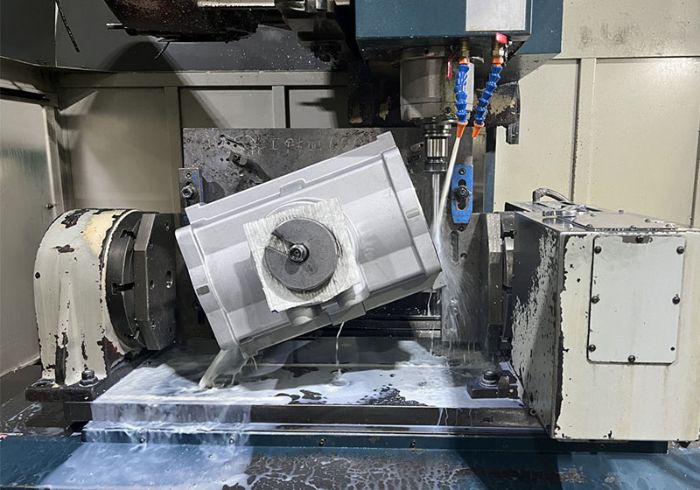

CNC Machining in Innovaw

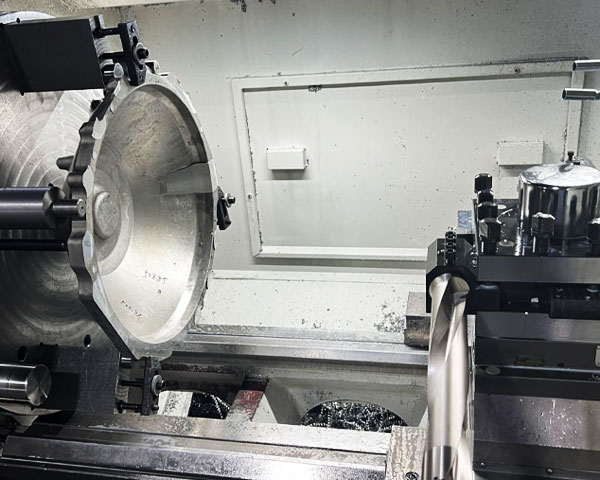

To meet customer requirement, Innovaw invested production line as well 15 years ago, currently there are more than 30 CNC machining centers including DMG Mori, Japan MAZAK and other brands, including CNC milling, turning, grinding, boring, drilling, tapping, reaming and other equipments. not just machining after casting and forging, but also machining directly from extrusion raw material.

Our CNC machining products cover automotive parts, transmission parts, parts used for medical equipment, aerospace, lighting fixtures, engineerng machinery, and other industries. machining size ranging from 10 * 20mm to the largest size of 1500 * 1000mm, the machining accuracy can reach 0.008μm, the surface roughness range between 3.2 μm Ra to 0.4 μm Ra. Depending on the complexity of the parts, the daily production capacity is about 1500-15000 parts.

Products on CNC Machining

Material Scope

- Materials

Metals: Aluminum, steel, titanium, brass, and copper

Plastics: ABS, Nylon, PTFE (Teflon), and others

Composites: Carbon fiber, fiberglass, etc.

Wood: For furniture making or prototypes

How CNC Machining Works

CNC machining is used as a manufacturing process that utilizes computer control to direct the movement of tools and machinery. In CNC machining, a computer program directs the machine to perform various operations such as cutting, drilling, milling and grinding. The process produces high-precision parts with complex shapes and excellent physical characteristics, increasing efficiency, reducing human error and achieving consistency in production.

Why Innovaw CNC Machining

Innovaw's primary mission is to meet customer expectations in quality, delivery, and performance. CNC machining, not just for die casting, but also for customer service. Innovaw has continued to invest in the machining sector, resulting in its current competitiveness.

Production Capability

With complete productivity software and hardware and standardized plant, Daily capacity 1500-15000 parts.

With complete production management process, more than 20 production management experts and hundreds of workers provide professional production service for customers every day.

We provide one-stop service for the whole process from mold development to PPAP approval, from casting to surface treatment.

Technical Capability

We are able to provide a full range of CNC machining services, including CNC milling, CNC turning, grinding, boring, drilling, tapping, reaming and inspection.

Multi-axis CNC machining, more complex geometry in one clamping.

Computer-aided manufacturing software for better simulation, tool path optimization and improved machining strategies.

Equipped with advanced sensors and feedback systems, real-time monitoring of the machining process.

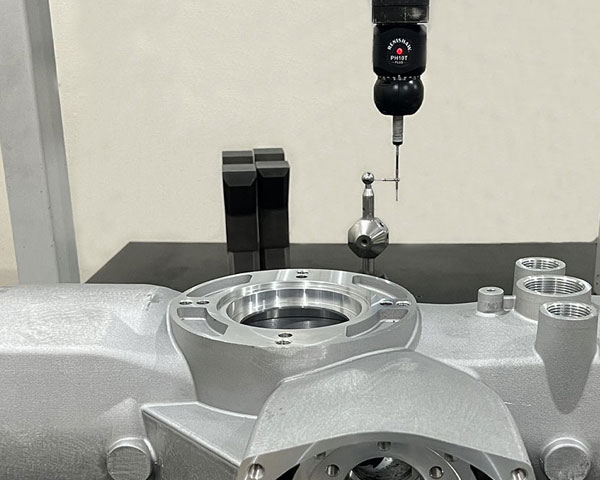

Quality Control

Our CNC machining products take IATF 16949 quality management system as the implementation standard.

We utilize core tools such as APQP, FMEA, PPAP, MSA, SPC, etc. to achieve production process control.

Process audits are regularly conducted through VDA6.3 and product audits are regularly conducted through VDA6.5.

Regularly use 8D analysis and report to deal with customer complaints and solve problems from the root cause.

All products need to pass the whole process inspection, including Spectrometer, 3D scan, X-ray, ZEISS CMM, etc. from the first article to final inspection.

CNC Machining FAQs

Q1. What are the main types of CNC Machining?

The main types of CNC machining include milling, turning, drilling, grinding, and electrical discharge machining (EDM).

Q2. Can CNC Machining only be used for aluminum castings?

No, CNC machining can process various materials beyond aluminum, including steel, titanium, plastics, and composites.

Q3. What metal materials can CNC Machining be applied to?

CNC machining can be applied to metals like aluminum, steel, brass, titanium, and even high-temperature alloys like Inconel.

Q4. How do I know if my parts require CNC Machining?

Yes, CNC machining typically delivers faster than casting for prototypes and low-volume production due to no mold requirements.

Q5. How do I know if my parts require CNC Machining?

Choose CNC machining if your parts need high precision, tight tolerances, or complex geometries that are difficult to cast.

Q6. In which industries is CNC Machining mainly used?

CNC machining is widely used in aerospace, automotive, medical, electronics, and defense industries for precision components.

Q7. CNC Machining vs. Traditional Machining

Speed and Automation: CNC machining is far more automated, while traditional machining often requires significant operator input.

Precision and Complexity: CNC can achieve higher precision and handle more complex parts, while traditional methods may require more time for intricate features.

Labor Costs: CNC machining can reduce labor costs because it's more automated, whereas traditional machining requires skilled labor for setup and operation.

CNC machining is a cornerstone of modern manufacturing, providing high precision and versatility for producing a wide range of parts across industries. It has revolutionized the way we make everything from tiny, intricate components to large industrial parts.

Q8. Why use the CNC Machining process to manufacture your product?

In the manufacturing industry, CNC Machining is an appropriate choice if your product has the following characteristics:

1. When to choose CNC Machining

- High precision requirements: If the part tolerance requirements within ±0.01mm, then traditional machining methods are often difficult to ensure that CNC Machining has excellent repeatability, can easily meet the needs of high-precision manufacturing.

- Complex structure or non-standard geometry: For parts with complex curved surfaces or shaped structures, CNC can realize three-axis, four-axis or even five-axis simultaneous machining, breaking through the limitations of the traditional process in the structure.

- Small batch diversified production: If the product is customized, small batch production needs, CNC doesn't need to open the mold, modify the design is also more flexible, is the ideal solution for small batch precision manufacturing.

- Material diversity, special performance: CNC can handle various materials from metals to plastics with consistent quality.

2. Key advantages of CNC Machining

- High repeatability: CNC through the program control, to avoid manual errors, to achieve high repeatability and dimensional consistency.

- Fast turnaround: Once the design is finalized, it can be quickly programmed and put into production, which is suitable for projects that require fast sampling or expedited delivery.

- Cost-effective for prototypes: Compared with injection molding, die-casting, etc., CNC doesn't need to open the mold, saving the initial investment, especially suitable for start-up projects or trial production stage.

- Complex feature capability: Can deal with the details of traditional equipment is difficult to complete, such as internal cavities, oblique holes, shaped cutting, etc., with a higher degree of freedom of processing.

- Easy to modify and iterate: Design changes can be quickly implemented without expensive tooling changes.

CNC Machining is a flexible, efficient and precise manufacturing method, which is especially suitable for the production of parts with high quality and process requirements.