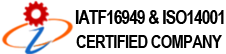

Custom aluminum CNC machining requires precision, experience, and advanced equipment. As a professional CNC machining manufacturer in China, we specialize in producing high-quality custom aluminum parts for global customers. From rapid prototyping to high-volume production, we deliver accurate, durable, and cost-effective aluminum CNC machining solutions tailored to your exact requirements.

Our experienced engineers use state-of-the-art CNC machines to manufacture precision aluminum components with tight tolerances and excellent surface finishes. Contact us today to learn more about our China custom aluminum CNC machining services.

At our China-based aluminum CNC machining facility, we offer comprehensive machining capabilities for custom aluminum parts. Equipped with advanced CNC milling and turning machines, we can manufacture complex components with high precision, repeatability, and consistent quality.

Our aluminum CNC machining services support a wide range of industries and applications, ensuring that every part meets your specifications, performance requirements, and international quality standards.

Aluminum CNC milling is an efficient and precise method for producing complex aluminum parts. Using modern CNC milling machines, we can manufacture components in various shapes, sizes, and thicknesses with excellent accuracy.

Our automated milling processes ensure fast lead times, stable quality, and high repeatability, making aluminum CNC milling ideal for both prototyping and production.

Aluminum CNC turning is used to produce cylindrical and rotational aluminum parts with high dimensional accuracy. This process is well suited for components that require smooth surfaces and precise tolerances.

Our CNC turning services allow us to manufacture aluminum parts with complex contours and consistent quality, making them suitable for aerospace, medical, automotive, and industrial applications.

Trusted aluminum CNC machining partner serving industrial customers worldwide.

Precision CNC-machined aluminum parts for aerospace applications, including brackets, housings, and structural components requiring tight tolerances and high strength.

Custom aluminum CNC milling and turning for automotive components such as mounts, enclosures, and lightweight structural parts.

CNC-machined aluminum enclosures, panels, and housings with anodizing and surface finishing for electronics and industrial equipment.

Rapid CNC machining of custom aluminum prototypes and small-batch production parts based on customer drawings and 3D files.

High-strength CNC-machined aluminum components used in construction equipment, fixtures, and architectural applications.

CNC turning, drilling, and milling of aluminum tubes and shafts for machinery, automation systems, and industrial equipment.

We specialize in manufacturing custom aluminum CNC machined parts for automotive, aerospace, marine, electronics, and industrial applications. Whether you need simple components or complex assemblies, we can meet your exact requirements.

We can CNC mill aluminum sheets of various thicknesses and provide engraving and anodizing services. We also customize aluminum tubes using turning, cutting, and drilling processes according to your drawings.

Choosing the right surface finish is essential for aluminum CNC machined parts. Depending on your application, we offer a wide range of finishing options to improve appearance, corrosion resistance, and functionality.

Available finishes include anodizing, black oxide, sandblasting, shot blasting, polishing, electrophoresis, chromate conversion, powder coating, and painting.

With years of experience in aluminum CNC machining, we specialize in producing parts with complex geometries and strict technical requirements using advanced CNC processes.

We serve demanding industries such as aerospace and medical manufacturing, delivering aluminum parts with high accuracy and tight tolerances.

Our skilled engineers focus on optimized designs, stable manufacturing processes, and long-lasting product performance.

Our factory is equipped with 3-axis, 4-axis, and 5-axis CNC machines, offering milling, turning, drilling, knurling, and other precision machining services.

Quality is our top priority in aluminum CNC machining. We implement strict quality control measures throughout the entire production process.

We carefully inspect raw materials, apply controlled machining processes, and conduct in-process and final inspections using precision testing equipment to ensure consistent quality and compliance with specifications.

In addition to aluminum, we also provide CNC machining services for other materials, including stainless steel, titanium, brass, copper, and engineering plastics.

Contact us to learn more about alternative materials and their applications in CNC machining.

Aluminum CNC machining is a precision manufacturing process that uses computer-controlled machines to cut and shape aluminum parts with high accuracy.

Aluminum offers excellent machinability, lightweight properties, corrosion resistance, and high strength, making it ideal for CNC machining.

The cost of aluminum CNC machining depends on part complexity, dimensions, quantity, machining time, and aluminum alloy. Contact us for an accurate quote based on your project requirements.

We operate under an ISO 9001:2015 quality management system, ensuring consistent quality, precision, and reliability.

Choose a manufacturer with proven experience, advanced equipment, strict quality control, and transparent communication. Comparing multiple quotes can help ensure the right supplier for your project.

We provide complete aluminum CNC machining solutions, from prototypes to mass production. Our experienced team ensures smooth project execution, reliable delivery, and consistent quality.

Contact us today to discuss your custom aluminum CNC machining needs and receive a free quote.