Top 10 Aluminium Sand Casting Foundries and Manufacturers in the World

_1761893100_WNo_1600d900.webp)

Are you searching for the best Aluminium Sand Casting Foundries to bring your metal parts to life? Wondering which Aluminium Sand Casting Manufacturers can provide precision, reliability, and scalability? Curious about how top foundries around the world handle complex casting projects efficiently?

In this article, we highlight the leading aluminium sand casting foundries and manufacturers globally, providing insights into their expertise, main products, services, and industry applications. You’ll discover which companies specialize in custom sand casting, tooling, CNC machining, finishing, and prototyping, helping you make informed decisions when sourcing high-quality metal components for automotive, aerospace, industrial, and defense projects.

We will explore the top 10 aluminium sand casting foundries, including established industry leaders and innovative modern manufacturers, showcasing their capabilities and achievements. Keep reading to find the right partner for your casting needs and learn how these companies transform raw aluminum into precise, high-performance components.

List of the Top 10 Aluminium Sand Casting Foundries and Manufacturers in the World

| Brand | Headquarters | Main Products and Services |

|---|---|---|

| 1. Boose Aluminum Foundry Co., Inc. | Stevens, Pennsylvania, USA | Custom aluminum sand castings, pattern/tooling design, finishing, quality support |

| 2. Foundrion Group | North York, Ontario, Canada | Aluminum sand casting, heat treating, rapid prototyping, CNC machining, alloy solutions |

| 3. Gabrian International (H.K.) Ltd. | Dover, New Hampshire, USA | Aluminum extrusion & die casting, sheet metal, CNC machining, electronics, plastics |

| 4. LeClaire Manufacturing Co. | Bettendorf, Iowa, USA | Aluminum sand & permanent mold casting, CNC machining, prototyping, finishing |

| 5. JC Casting (Investment Casting PCI) | Dongying, Shandong, China | Investment casting, sand casting, CNC machining, design & OEM services |

| 6. Bremer Manufacturing Company, Inc. | Elkhart Lake, Wisconsin, USA | Custom aluminum sand casting, CNC machining, heat treating, assembly, engineering support |

| 7. Alu Die Casting / GC Precision Mold Co., Ltd. | Dongguan, Guangdong, China | Die casting (Al, Zn, Mg, Cu), sand & gravity casting, CNC machining, surface finishing |

| 8. Grainger & Worrall / Evolution Castings Group Limited | Bridgnorth, UK | Complex sand casting, prototyping, precision machining, assembly, engineering support |

| 9. Alcast Company | Peoria, Illinois, USA | Permanent mold aluminum casting, CNC machining, heat treating, finishing, assembly |

| 10. Innovaw | Ningbo, China | Aluminum & zinc die casting, CNC machining, prototyping, surface finishing, assembly |

1. Boose Aluminum Foundry Co., Inc.

Introduction:

Boose Aluminum Foundry Co., Inc. has earned a stellar reputation as a leading aluminium sand casting manufacturer in the United States. Located in Stevens, Pennsylvania, this family-owned foundry has been delivering precision aluminum castings for nearly a century, serving industries such as defense, medical imaging, robotics, power generation, and commercial machinery. Boose Aluminum Foundry specializes in high-quality, custom aluminum sand castings, combining traditional craftsmanship with modern technologies to meet exacting client specifications and maintain consistent product excellence.

With decades of expertise, Boose Aluminum Foundry provides full-service solutions including pattern design, tooling, casting, finishing, and quality inspection, tailored for businesses seeking reliable aluminium sand casting suppliers or custom manufacturing partners. Their dedication to personalized service and stringent quality standards makes them a preferred partner for companies requiring durable, precision-engineered aluminum castings. By emphasizing flexible production capabilities and proactive collaboration with clients, Boose ensures every casting project—from prototypes to high-volume production—meets technical requirements and exceeds expectations.

Established: 1933

Headquarters: Stevens, Pennsylvania, USA

Main Products and Services:

- Custom aluminum sand castings for industrial, commercial, and defense applications

- Pattern and tooling design for precision castings

- Complete casting production and finishing services

- Technical support and consultation for specialized aluminium casting projects

2. Foundrion Group

Introduction:

Foundrion Group is a leading North American network of eleven premier sand and metal casting foundries strategically located across the United States and Canada. Specializing in aluminium sand casting, metal casting, and advanced alloy solutions, Foundrion Group leverages decades of combined expertise to deliver precision castings for aerospace, industrial machinery, water works, fire protection, and military applications. Their facilities are equipped with modern foundry technologies, enabling them to handle complex and high-performance casting projects with reliability and quality.

Foundrion Group offers a comprehensive suite of services including sand casting, die and steel casting, heat treating, 3D scanning and printing, reverse engineering, rapid prototyping, machining, material testing, and other value-added processes. By integrating engineering support with flexible production capabilities, they provide businesses seeking aluminium sand casting manufacturers or foundries with a trusted partner capable of meeting exact specifications, improving part performance, and ensuring timely delivery across multiple industries.

Established: 2022

Headquarters: North York, Ontario, Canada

Main Products and Services:

- Aluminium sand castings and metal castings for aerospace, industrial, and commercial applications

- Heat treating and metallurgical support to enhance material properties

- In-house pattern creation, reverse engineering, and rapid prototyping

- High-precision machining and quality assurance testing

- Alloy expertise and custom casting solutions for complex projects

3. Gabrian International (H.K.) Ltd.

Introduction:

Gabrian International (H.K.) Ltd. connects North American and European companies with high-quality manufacturing partners across China and India. Specializing in aluminum extrusion, die casting, sheet metal, and related manufacturing solutions, Gabrian helps OEMs extend their supply chains overseas while maintaining strict quality control, timely delivery, and clear communication. Their expertise allows clients to manage complex projects with confidence, from concept and prototyping to production and logistics.

Gabrian International provides a full suite of services including aluminum and metal castings, electronics manufacturing, plastics production, quality assurance, and on-the-ground project management. With offices in the USA, China, and India, they combine local knowledge with global reach to ensure every product meets industry standards and client specifications. Their network of vetted suppliers and experienced team supports companies seeking reliable partners for aluminum casting and extrusion, helping reduce costs while ensuring consistent quality and performance across all projects.

Established: 1995

Headquarters: Dover, New Hampshire, USA

Main Products and Services:

- Aluminum extrusion and die casting solutions

- Sheet metal fabrication and CNC machining

- Electronics manufacturing including PCB assembly and magnetics

- Plastics manufacturing and injection molding

- Project management, quality control, and supply chain support across Asia

4. LeClaire Manufacturing Co.

Introduction:

LeClaire Manufacturing Co., based in Bettendorf, Iowa, specializes in aluminum sand casting and permanent mold casting, delivering precise, porosity-free parts for a wide range of industries. With a focus on automation, advanced tooling, and in-house core making, LeClaire ensures consistent quality and on-time delivery. Their vertically integrated process—from pattern creation and metal pouring to heat treating, machining, and finishing—allows customers to manage complex projects efficiently while maintaining high standards across all aluminum casting applications.

LeClaire serves diverse sectors including agriculture, heavy trucks, marine, military and defense, engine components, valves and pumps, and recreational vehicles. Their full-service capabilities encompass sand and permanent mold casting, CNC machining, tool and die manufacturing, prototyping, heat treating, x-raying, anodizing, and painting. The company’s family-owned heritage and decades of metallurgical expertise make it a trusted partner for custom aluminum casting solutions, supporting both small and large-scale production needs.

Established: 1966

Headquarters: Bettendorf, Iowa, USA

Main Products and Services:

- Aluminum sand casting and permanent mold casting

- CNC machining and precision finishing

- Tool and die manufacturing, core making, and prototyping

- Heat treating, real-time x-raying, anodizing, and painting

- Engineering and design support for custom casting projects

5. JC Casting (Investment Casting PCI)

Introduction:

JC Casting, also known as Investment Casting PCI, is a leading global manufacturer and supplier of investment castings, sand castings, and precision machining services. JC Casting operates two in-house factories and partners with two additional facilities to meet diverse industrial needs. The company employs over 300 workers, including engineers, QC personnel, and sales staff, to ensure high-quality production and on-time delivery.

JC Casting specializes in producing components from a variety of metals including alloy steel, carbon steel, stainless steel, aluminum, and non-ferrous alloys. Using advanced techniques such as lost wax investment casting, water glass casting, sand casting, and CNC machining, the company serves industries including construction, machinery, medical, aerospace, petroleum, and more. Their vertically integrated process covers design, molding, casting, machining, heat treatment, and quality inspection, providing end-to-end solutions from prototypes to full-scale production.

Established: 1997

Headquarters: Dongying, Shandong, China

Main Products and Services:

- Investment casting (lost wax, water glass)

- Sand casting and aluminum casting

- CNC machining and post-treatment

- Design support, OEM & ODM solutions, and engineering consultancy

- Quality assurance with ISO-certified processes and on-time delivery

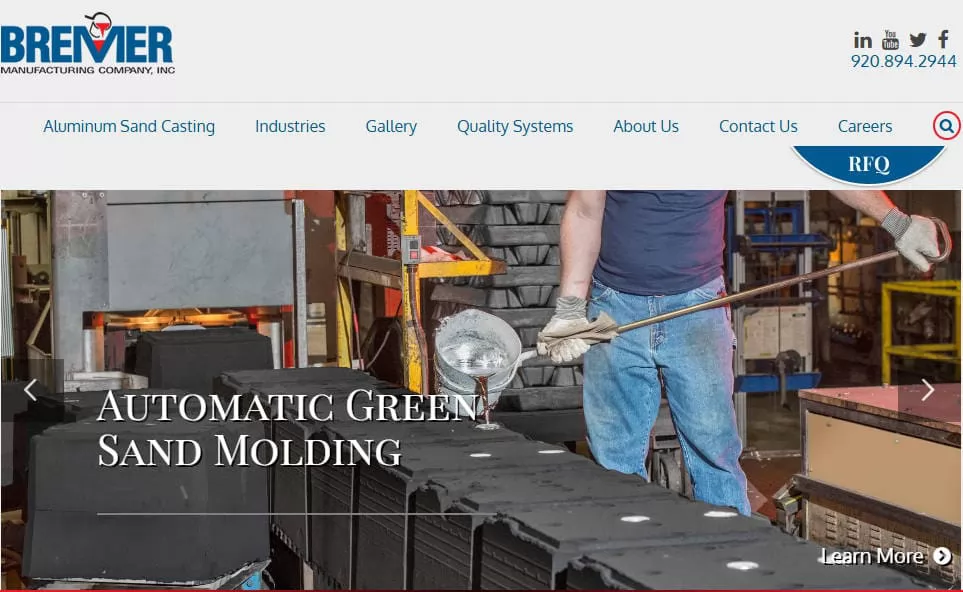

6. Bremer Manufacturing Company, Inc.

Introduction:

Bremer Manufacturing Company, Inc. is a privately held aluminum sand casting foundry located in Elkhart Lake, Wisconsin. With over 75 years of experience, Bremer specializes in custom aluminum sand casting for both high- and low-volume production. Their expertise spans complex, highly-cored aluminum castings ranging from a few ounces to 125 pounds, serving industries such as automotive, heavy machinery, agriculture, and defense.

Their modern 66,300-square-foot facility houses state-of-the-art equipment for green sand and air set molding, in-house core making, heat treating, CNC machining, and assembly. Bremer’s skilled engineering team provides design support, tooling guidance, and project management, offering a fully integrated casting solution from concept to finished product. The company maintains ISO 9001:2015 certification and ITAR registration, ensuring quality and regulatory compliance for every project.

Headquarters: Elkhart Lake, Wisconsin, USA

Main Products and Services:

- Custom aluminum sand casting (green sand, air set/no-bake molding)

- CNC machining of aluminum castings

- In-house heat treating (T5, T51, T6, T61, T7)

- Assembly of cast components (thread inserts, dowels, tubes, studs, plugs)

- Engineering support and product design assistance

- Stocking and supply chain/logistics solutions

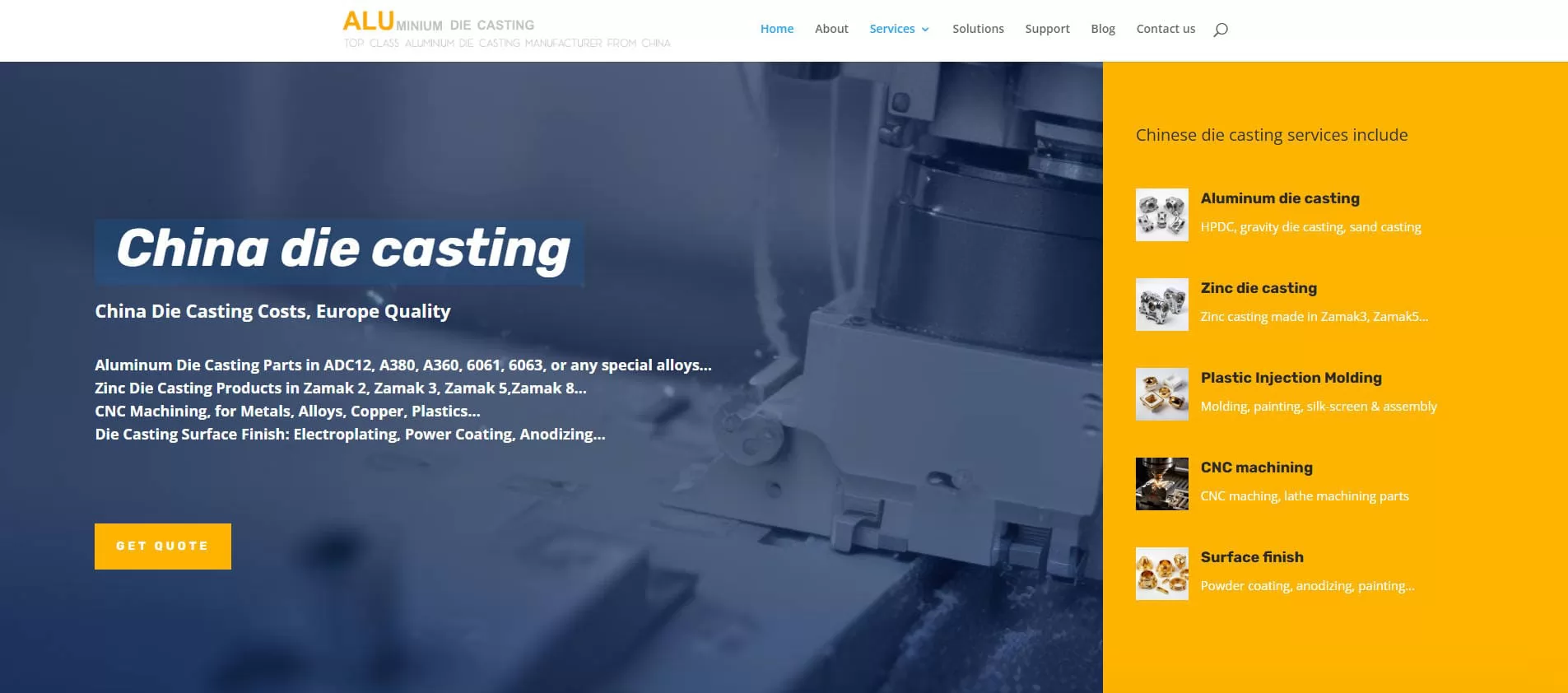

7. Alu Die Casting / GC Precision Mold Co., Ltd.

Introduction:

Alu Die Casting, operated by GC Precision Mold Co., Ltd., is a leading Chinese manufacturer of high-quality die casting molds and die-cast parts. The company specializes in aluminum, zinc, magnesium, and copper die casting, as well as sand casting, gravity casting, and forging casting. They also provide CNC precision machining, plastic injection molding, surface finishing, and assembly services for a variety of industries, including automotive, electronics, aerospace, and consumer products.

With over 20 years of experience, Alu Die Casting has developed a reputation for precision, quality, and reliability. Their facilities include high-pressure die casting machines (120–2000 tons), gravity casting machines (up to 50 kg), injection molding machines (80–3000 tons), and advanced quality control systems, including CMM inspection and in-process verification.

Established: 1999

Headquarters: Dongguan City, Guangdong Province, China

Main Products and Services:

- Aluminum, zinc, magnesium, and copper die casting

- Sand casting, gravity casting, and forging casting

- CNC precision machining and plastic injection molding

- Surface finishing: anodizing, powder coating, plating, painting

- Custom mold design and tooling up to 2 meters / 20 tons

8. Grainger & Worrall / Evolution Castings Group Limited

Introduction:

Grainger & Worrall, now part of Evolution Castings Group Limited, is a UK-based global leader in complex sand casting. The company has nearly 80 years of experience in producing high-precision castings for automotive, motorsport, aerospace, defense, marine, power generation, and infrastructure sectors. They specialize in rapid prototyping, giga-scale sand casting, and lightweight complex metal shapes, supporting projects from concept design to finished assemblies.

Operating multiple foundries and state-of-the-art machining facilities, Grainger & Worrall employs advanced technologies such as robotic fettling, core blowing, sand reclamation, digital sand printing, and precision machining. They are committed to sustainability, energy efficiency, and innovative lightweighting, and have been awarded multiple Queen’s Awards for Export and Innovation.

Established: 1946

Headquarters: Bridgnorth, Shropshire, United Kingdom

Main Products and Services:

- Complex aluminum and metal sand casting (prototype to giga-scale)

- Rapid prototyping and tool design

- Precision machining and finishing

- Assembly of cast components

- Design consultancy and project engineering support

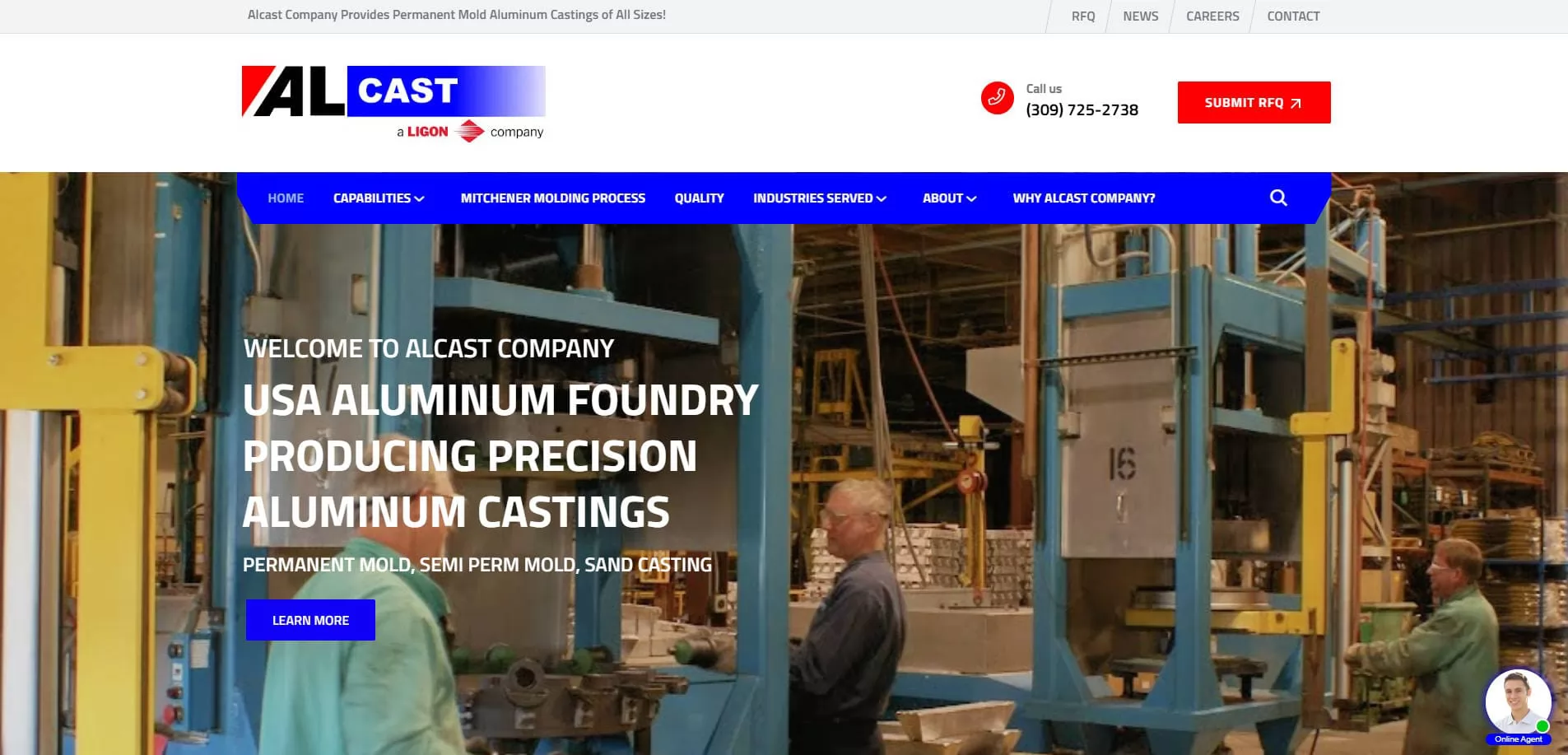

9. Alcast Company

Introduction:

Alcast Company is a leading permanent mold aluminum foundry and CNC machine shop. The company specializes in low-pressure, electro-magnetic permanent mold aluminum castings. With over 50 years of experience, Alcast produces high-quality castings ranging from fractions of a pound to over 350 pounds, serving industries including automotive, aerospace, industrial manufacturing, and recreation.

The company operates proprietary Mitchener Molding Machines and maintains full in-house capabilities for heat treating, CNC machining, X-ray inspection, and value-added services. Alcast is ISO 9001:2015 and PED 2014 certified, ensuring precision, quality, and reliability in every casting project.

Established: 1970

Headquarters: Peoria, Illinois, USA

Main Products and Services:

- Permanent mold aluminum casting (low-pressure, electro-magnetic)

- CNC machining and finishing of aluminum castings

- Heat treating and surface coatings (powder coating, anodizing, plating)

- Prototyping, tooling, and engineering support

- Value-added assembly and packaging of cast components

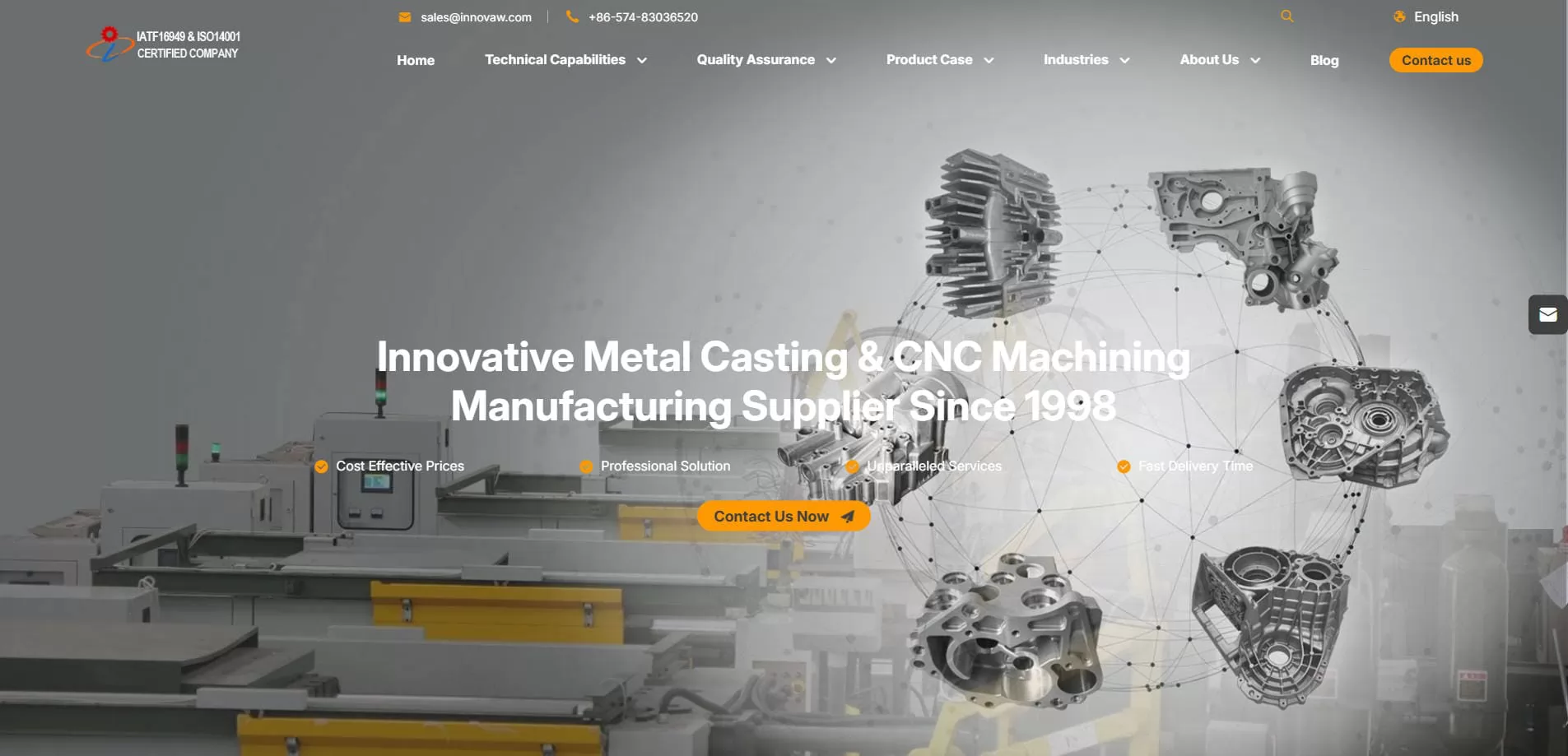

10. Innovaw

Introduction:

Innovaw is a professional manufacturer of aluminum and zinc castings with over 20 years of experience. The company specializes in high-pressure die casting, low-pressure die casting, gravity casting, investment casting, aluminum sand casting, and CNC precision machining. Innovaw provides one-stop solutions from rapid prototyping and tooling design to finished product delivery for industries including automotive, aerospace, marine, medical, energy, and LED lighting.

With a team of over 580 employees, including development engineers and industry experts, Innovaw ensures high-quality production with ISO 9001/IATF 16949, ISO 14001, and ISO 45001 certifications. The company emphasizes engineering support, process optimization, and value-added services such as surface finishing, assembly, and quality inspection.

Headquarters: Ningbo, China

Main Products and Services:

- Aluminum and zinc die casting (high pressure, low pressure, gravity, investment casting)

- CNC machining and precision finishing

- Rapid prototyping and mold/tooling design

- Surface treatments including painting, powder coating, anodizing, and plating

- Engineering support, quality inspection, and value-added assembly

Understand Your Specific Needs

Before choosing an aluminium sand casting foundry, it’s important to understand your specific technical and performance requirements. Are you producing large, structurally strong components, or lightweight parts with moderate precision? Do your products require specific alloy compositions, heat treatment, machining, or surface finishing processes?

Pro Tip: Evaluate your component’s working environment. High-temperature or high-load applications typically require specialized aluminium alloys and advanced molding techniques to ensure durability and safety.

Research the Foundry’s Expertise

Aluminium sand casting foundries vary significantly in technical capability, equipment level, and engineering knowledge. Leading foundries invest in 3D sand printing, precision molding lines, professional gating design, and quality simulation tools to ensure stable casting performance.

Pro Tip: Ask for previous project samples, process documentation, and certifications such as ISO 9001, ISO 14001, or related industry-specific credentials to confirm their professionalism.

Quality and Durability

The quality of aluminium sand cast parts is heavily influenced by mold preparation, sand quality, pouring temperature, alloy selection, and heat treatment. Reliable foundries implement strict quality controls such as chemical composition testing, hardness checks, CT/X-ray inspection, and CNC finish machining.

Pro Tip: Ask the manufacturer about defect control, porosity testing, and structural integrity inspection. These factors reflect the foundry’s consistency and production stability.

Who Are the Best Aluminium Sand Casting Foundries?

The global aluminium sand casting industry includes well-established foundries such as Metal Technologies, Furness Foundry, Gamma Foundries, Harrison Castings, and several recognized Asian manufacturers. These foundries are known for their robust engineering capability, high-capacity molding lines, and long-term expertise in structural aluminium components. Meanwhile, many fast-growing Chinese foundries have gained global recognition for balancing precision, cost-effectiveness, and fast delivery.

The demand for aluminium sand casting continues to expand across industries such as automotive, heavy machinery, energy, transportation, marine engineering, and industrial equipment. Sand casting remains a preferred solution for producing large, complex, and durable aluminium components.

What Should You Pay Attention to When Looking for an Aluminium Sand Casting Foundry?

When selecting an aluminium sand casting supplier, several key factors must be assessed, such as engineering strength, mold design expertise, metal flow simulation capability, sand quality control, machining capability, and production capacity.

Product Quality: High-quality sand castings require stable molding conditions, consistent alloy composition, and reliable pouring systems. Look for foundries with advanced molding lines and extensive inspection procedures.

Customization Ability: Many industrial applications need tailored tooling, special alloys, precision machining, and custom finishing. Ensure the foundry offers full customization services for your project.

Production Capacity: For medium-to-large components or long-term supply programs, choose a foundry with automated molding lines, large furnaces, and CNC machining capacity.

Compliance: Certifications like ISO 9001, ISO 14001, and environmental compliance documents are important indicators of manufacturing reliability.

Lead Time and Delivery: Reliable production planning and timely shipping ensure your project stays on schedule.

Cost: Pricing should reflect a balance between quality, engineering expertise, and casting stability. Extremely low prices can indicate risks such as poor sand quality, inconsistent molding, or weak process control.

Where Can You Find Reliable Aluminium Sand Casting Foundries?

You can find trustworthy aluminium sand casting suppliers through multiple channels, depending on your project size and sourcing needs.

Industry Trade Shows: Events like GIFA, CIIF, and Hannover Messe offer opportunities to inspect samples, discuss technical needs, and evaluate supplier capability directly.

Online B2B Platforms: Websites like Alibaba, Made-in-China, and Global Sources list verified aluminium sand casting manufacturers with detailed profiles and certifications.

Industry Associations: Professional associations offer access to vetted suppliers with reliable production capability.

Recommendations and Referrals: Many companies discover excellent suppliers through referrals within the same industry.

Supplier Directories: Platforms such as ThomasNet or QIMA provide extensive listings of certified aluminium sand casting foundries, including capabilities, equipment, and qualifications.

Company Websites: Visiting the official website of potential partners helps you evaluate their manufacturing scale, equipment list, certifications, and engineering capabilities.

Why Choose to Cooperate with a Chinese Aluminium Sand Casting Foundry?

Chinese aluminium sand casting foundries are well-known for their competitive pricing, advanced production lines, strong engineering capability, and rapid manufacturing cycles. China’s industrial ecosystem provides efficient material supply, tooling development, machining, and surface treatment support.

Cost-Effectiveness: Integrated supply chains and large-scale production allow Chinese foundries to offer high-quality castings at competitive prices.

Wide Product Range: Chinese foundries can produce components for automotive, industrial machinery, pumps/valves, marine, energy equipment, and construction machinery.

Advanced Manufacturing Technology: Many suppliers use 3D sand printing, vacuum casting, automated molding lines, and controlled cooling processes for higher precision and strength.

High Production Capacity: Large foundries operate multiple melting furnaces, big-format molding machines, and CNC machining centers to support large-volume orders.

Global Export Expertise: Many foundries export worldwide and are experienced with logistics, packaging, inspection standards, and international certifications.

Comprehensive Support: Chinese suppliers typically provide mold development, process optimization, machining, surface finishing, and long-term production support.

How to Choose the Best Aluminium Sand Casting Foundry for Your Project?

For companies requiring medium-to-large aluminium castings, selecting a reliable foundry is essential. Innovaw is a trusted partner for global customers, providing advanced aluminium casting solutions and consistent manufacturing quality.

Innovaw meets all the key criteria for top-tier aluminium sand casting and offers strong engineering support from concept to mass production. Here are some key reasons why Innovaw is a top choice for international buyers:

Extensive Experience: Innovaw has deep experience in aluminium sand casting, tooling development, alloy optimization, and large-scale manufacturing.

Engineering Collaboration: Innovaw works closely with industrial designers and engineers to enhance component strength, reduce weight, and improve overall performance.

Advanced Facilities: Equipped with precision molding systems, automated lines, and CNC machining centers, Innovaw ensures consistent quality and repeatability.

Award-Winning Quality: Innovaw has received industry awards for casting quality and production technology, showcasing its commitment to excellence.

A Premium Alternative to Global Brands: Innovaw delivers high-end quality comparable to globally recognized foundries but with more competitive pricing, flexible service, and faster response times.

Conclusion

The aluminum casting industry has a long and diverse history, with numerous foundries around the world providing specialized solutions for automotive, aerospace, industrial, and defense applications. From traditional sand casting and investment casting to advanced die casting and CNC machining, manufacturers are continuously innovating to meet the demand for high-precision, durable, and cost-effective metal components. Companies such as Boose Aluminum Foundry, LeClaire Manufacturing, and Alcast Company exemplify the range of expertise available, offering services from prototyping and tooling design to finishing and assembly.

Amid this competitive landscape, Innovaw stands out as a modern, customer-focused solution provider. Based in Ningbo, China, Innovaw combines over 20 years of experience in high-pressure, low-pressure, gravity, and investment casting with precision CNC machining and surface finishing capabilities. The company offers end-to-end services, from rapid prototyping and mold design to final product delivery, ensuring high quality, timely production, and tailored solutions for industries including automotive, aerospace, marine, medical, and LED lighting.

With a strong engineering team, robust quality control systems, and global experience, Innovaw is positioned as a reliable partner for businesses seeking innovative and scalable aluminum and zinc casting solutions. By integrating advanced technology with dedicated service, Innovaw enables clients to transform ideas into precise, high-performance metal components efficiently and reliably.

-

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World -

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China -

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

-

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China -

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World -

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China -

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China