Top 10 Aluminium Casting Foundries and Companies in China

Are you searching for the best aluminium casting foundries or reliable aluminium casting companies in China? Wondering which manufacturers offer the highest quality, most advanced capabilities, and the best value for your casting projects? With so many choices across China, how do you identify the right partner for your needs?

China has become a global leader in aluminum casting due to its strong industrial ecosystem, advanced manufacturing technologies, and competitive production costs. From die casting and gravity casting to low-pressure and sand casting, Chinese foundries now provide full-service solutions covering mold design, prototyping, CNC machining, surface finishing, and mass production. Whether you’re sourcing components for automotive, aerospace, electronics, industrial machinery, medical devices, or consumer products, China’s aluminum casting industry offers high precision, fast turnaround, and strict quality control that meet international standards. Many top-tier companies today integrate modern engineering tools, automated defect detection systems, and ISO/IATF-certified processes, ensuring both performance and reliability for global buyers.

In this article, we present the Top 10 Aluminium Casting Foundries and Companies in China, helping you quickly understand their strengths and choose the right partner for your project. Keep reading to explore the leading manufacturers and find the ideal supplier for your aluminum casting needs!

List of the Top 10 Aluminium Casting Foundries and Companies in China

| Brand | Headquarters | Main Products & Services |

|---|---|---|

| 1. Dolin Casting | Shanghai, China | Aluminum casting, sand casting, gravity casting, die casting, CNC machining |

| 2. Aludiecasting | Dongguan, China | Aluminum, magnesium & zinc die casting, CNC machining, surface finishing |

| 3. CNM Tech | Dongguan, China | Aluminum, zinc & magnesium die casting, CNC machining, mold design |

| 4. Pro Die Casting | Cangzhou, China | Aluminum die casting, LPDC, gravity casting, CNC machining, tooling |

| 5. Dongrun Casting | Yongkang, China | Aluminum sand casting, LPDC, HPDC, CNC machining, surface treatment |

| 6. ZP Aluminum | Foshan, China | Aluminum extrusion, casting, CNC machining, anodizing & powder coating |

| 7. Qingdao Longquan Hongda | Qingdao, China | Copper & aluminum casting, die casting, mold making, CNC machining |

| 8. Minghe | Dongguan, China | Aluminum, zinc & magnesium die casting, CNC machining, mold making |

| 9. OEFORM | Dongguan, China | Aluminum, zinc & magnesium die casting, mold design, CNC machining |

| 10. INNOVAW | Ningbo, China | Aluminum & zinc die casting, CNC machining, prototyping, surface finishing |

1. Dolin Casting

Introduction:

Founded in 1998, Dolin Casting Co., Ltd. is a premier aluminum casting company and foundry headquartered in Shanghai, China. With over 20 years of experience, Dolin Casting specializes in producing high-quality, fully machined, and customized aluminum castings for industrial applications. As a trusted aluminum casting factory and manufacturer, the company provides a comprehensive range of services including sand casting, gravity die casting, high-pressure die casting, low-pressure die casting, CNC machining, and finishing services. Dolin Casting is recognized for its ability to deliver complete aluminum casting solutions, from prototyping to mass production, supporting clients in automotive, architectural, electrical, medical, and outdoor furniture industries.

Dolin Casting’s strength lies in its integrated capabilities as an aluminum casting supplier and manufacturer. With a skilled team of over 120 professionals, the company emphasizes quality, precision, and customer satisfaction. Their aluminum casting foundry is equipped to handle complex geometries and tight tolerances, providing clients with durable and reliable cast components. Dolin Casting’s products are exported globally to markets in North America, Europe, Australia, and Asia, making it a go-to partner for businesses seeking a dependable aluminum casting company for OEM solutions, custom designs, and professional technical support.

Established: 1998

Headquarters: Shanghai, China

Key Products:

- Automotive aluminum casting parts

- Patio and outdoor furniture components

- Electrical enclosures and industrial equipment parts

- Medical and architectural aluminum castings

Services and Capabilities:

- Aluminum sand casting, gravity die casting, high and low-pressure die casting

- CNC machining and precision finishing services

- Custom engineering and prototype development

- One-stop aluminum casting solutions from design to delivery

2. Aludiecasting

Introduction:

Founded in 1999, Aludiecasting (GC Precision Mold Co., Ltd.) is a leading aluminum casting company and foundry located in Dongguan City, Guangdong Province, China. As a premier aluminum casting factory and manufacturer, the company specializes in delivering high-quality aluminum die casting, magnesium die casting, zinc die casting, and plastic injection molded components. Leveraging advanced die casting machinery and a skilled workforce, Aludiecasting provides reliable, fully customized aluminum castings for diverse industries including automotive, marine, electronics, lighting, and architectural hardware. Their expertise allows clients to source complete aluminum casting solutions from a single supplier, ensuring consistency, precision, and cost efficiency across all projects.

Aludiecasting stands out as a comprehensive aluminum casting supplier and foundry with a strong focus on engineering flexibility and production capacity. With capabilities spanning high-pressure die casting, gravity casting, sand casting, CNC machining, and surface finishing such as anodizing and powder coating, the company ensures that every aluminum casting meets stringent quality standards. Serving clients worldwide, Aludiecasting combines the benefits of an experienced aluminum casting manufacturer with modern technological processes, making it a trusted partner for businesses seeking customized, high-precision aluminum castings at competitive pricing.

Established: 1999

Headquarters: Dongguan City, Guangdong Province, China

Key Products:

- Aluminum die casting parts (ADC12, A380, A365, 6061, 6063)

- Zinc die casting parts (Zamak 2, 3, 5, 8)

- Magnesium die casting components

- Plastic injection molded parts

- CNC machined metal and plastic components

- Custom aluminum gravity castings and sand castings

Services and Capabilities:

- High-pressure, low-pressure, gravity, and sand die casting

- Die casting mold design and manufacturing up to 20-ton tooling

- Surface finishing: anodizing, powder coating, painting, chrome plating

- Precision CNC machining and assembly services

3. CNM Tech

Introduction:

CNM Tech (CN Manufacture Tech Co., Ltd.), established in 2005 and based in Dongguan City, Guangdong Province, China, is a top aluminum casting company and foundry. As a professional aluminum casting factory and manufacturer, CNM Tech specializes in aluminum die casting, zinc die casting, and magnesium die casting. The company provides complete aluminum casting solutions including cold and hot chamber die casting, CNC machining, metal stamping, and plastic mold design. With a focus on precision, efficiency, and reliability, CNM Tech serves industries ranging from automotive, bicycles, and lighting fixtures to decorative hardware, valves, and flow meter housings, offering customized aluminum castings tailored to specific client requirements.

CNM Tech combines advanced die casting machinery with a skilled team of engineers and mold designers, making it a leading aluminum casting supplier in China. The company employs state-of-the-art tooling, mold flow and cooling analysis, and automated quality control processes including CMM and real-time X-ray inspection to ensure high-precision components. CNM Tech’s integrated approach as an aluminum casting foundry and OEM manufacturer allows clients to source end-to-end solutions—from prototyping and tool design to high-volume production—while maintaining strict quality standards and on-time delivery, making it a trusted global partner for high-quality aluminum casting products.

Established: 2005

Headquarters: Dongguan City, Guangdong Province, China

Key Products:

- Aluminum die casting parts for automotive, lighting, bicycle, and industrial applications

- Zinc and magnesium die casting components

- Plastic injection molded parts and precision machined metal components

- Flow meter housings, valves, motor covers, and decorative hardware

Services and Capabilities:

- Cold and hot chamber die casting with high-precision tolerances

- CNC machining, metal stamping, and plastic mold manufacturing

- Mold design, mold flow and cooling analysis, and in-house tooling

- Surface treatments including powder coating, anodizing, painting, and plating

- End-to-end aluminum casting solutions from prototyping to mass production

4. Pro Die Casting

Introduction:

Established in 2000, Pro Die Casting is a premier aluminum casting manufacturer and global supplier based in Cangzhou, China. The company specializes in high-quality aluminum die casting, low pressure die casting, gravity die casting, investment casting, and sand casting. Pro Die Casting provides comprehensive solutions for industries including automotive, electronics, telecommunication, marine, and medical, delivering precise and durable aluminum components for diverse applications.

Pro Die Casting’s core strength lies in its fully integrated aluminium casting factory, offering end-to-end services from in-house tooling design and mold manufacturing to precision machining, sheet metal fabrication, and advanced surface treatments such as polishing, electroplating, powder coating, anodizing, and shot blasting. With state-of-the-art cold and low-pressure die casting machines ranging from 300 to 1250 tons and rigorous IATF 16949-compliant quality control, Pro Die Casting ensures reliable, high-precision, and cost-effective aluminum casting solutions worldwide.

Established: 2000

Headquarters: Cangzhou, Hebei, China

Key Products:

- Aluminum die casting parts for automotive, electronics, and marine applications

- Low pressure and gravity die casting components

- Investment and sand casting parts

- Precision CNC machined aluminum components

Technical Capabilities:

- In-house tooling design and mold manufacturing

- Cold and low-pressure die casting machines (300T–1250T)

- Advanced surface treatments: polishing, anodizing, powder coating, electroplating, shot blasting

- Precision CNC machining and sheet metal fabrication

- IATF 16949 and ISO 9001 certified quality control system

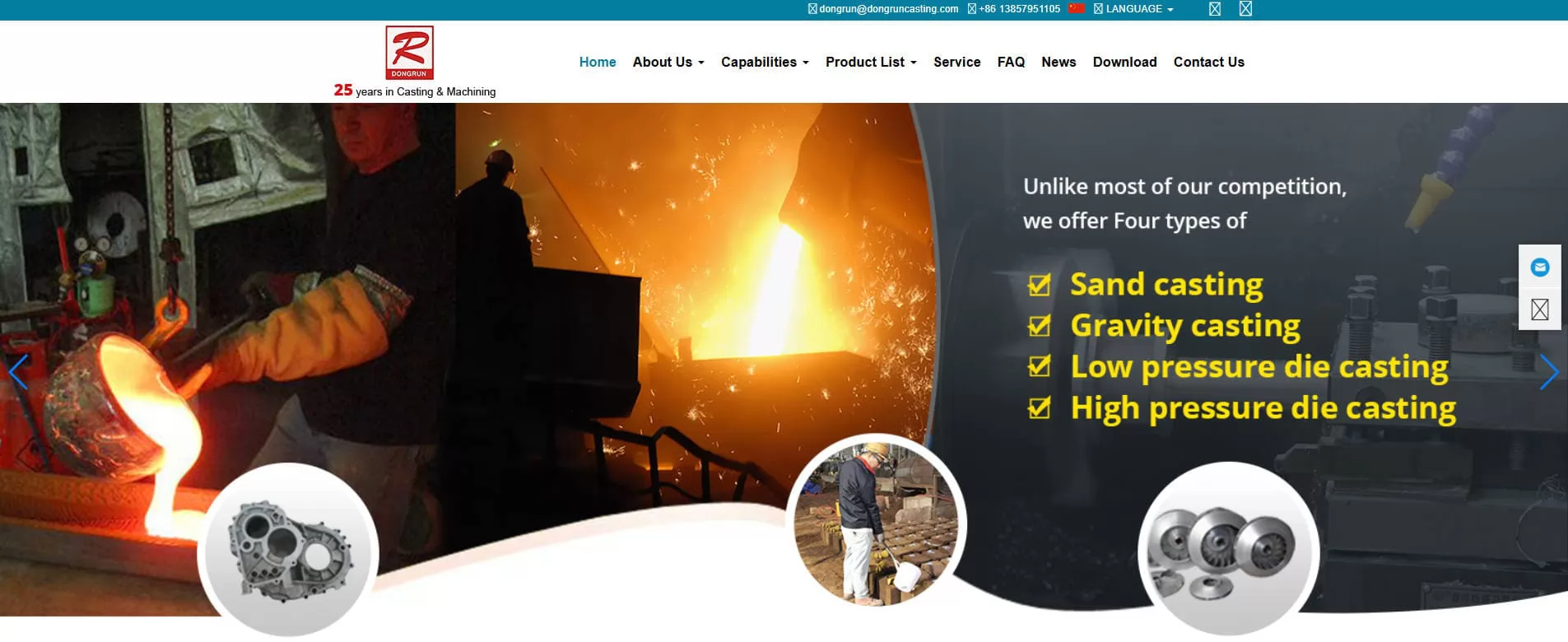

5. Dongrun Casting

Introduction:

Founded in 1995, Dongrun Casting Industry Co., Ltd. is a prominent aluminum casting manufacturer and supplier based in Yongkang, Zhejiang Province, China. With over 30 years of experience in the casting industry, the company offers a complete one-stop solution covering aluminum sand casting, gravity die casting, low-pressure die casting, high-pressure die casting, precision CNC machining, surface treatment, and comprehensive quality inspection. Dongrun Casting is dedicated to delivering high-precision, durable aluminum and zinc alloy parts for diverse industries including automotive, medical devices, electrical, lighting, HVAC, and industrial machinery.

The company’s core strengths lie in its fully integrated aluminium casting factory, advanced in-house tooling, and a strong focus on quality control. Dongrun Casting operates large-scale die casting machines capable of producing thin-walled and complex geometry parts with annual capacities exceeding 800 tons. With full-service CNC machining centers, sheet metal fabrication, and surface treatment workshops providing anodizing, powder coating, plating, shot blasting, and sandblasting, Dongrun ensures that every product meets international standards and customer specifications. Rigorous compliance with ISO 9001:2015 and IATF 16949 guarantees reliable, defect-free, and high-quality casting solutions worldwide.

Established: 1995

Headquarters: Yongkang City, Zhejiang Province, China

Key Products:

- Aluminum sand casting parts for automotive and industrial applications

- Gravity die casting and low-pressure die casting components

- High-pressure die casting parts with thin walls and complex geometries

- Precision CNC machined aluminum and zinc alloy parts

Technical Capabilities:

- In-house tooling design and mold manufacturing

- Cold, low-pressure, and high-pressure die casting machines (up to 1500 mm mold size)

- Surface finishing: anodizing, powder coating, electroplating, shot blasting, sandblasting

- Precision CNC machining and rapid prototyping (72-hour sample delivery)

- ISO 9001:2015 and IATF 16949 certified quality control with full-process traceability

6. ZP Aluminum

Introduction:

Founded in 2005, ZP Aluminum Co., Ltd. is a leading aluminum casting and CNC machining manufacturer based in Foshan, Guangdong, China. The company integrates research, development, manufacturing, and sales of aluminum profiles and precision-machined products. ZP Aluminum specializes in one-stop aluminum deep-processing solutions, providing high-quality aluminum extrusion, casting, CNC machining, surface treatment, and assembly services to customers worldwide.

ZP Aluminum operates two modern production bases covering over 50,000 square meters, including 12 extrusion lines ranging from 600 to 10,000 tons, over 30 high-precision CNC machines, anodizing and powder coating lines, and advanced metal fabrication facilities. The company supports customized OEM and ODM projects, delivering tailored aluminum products for industries such as construction, electronics, automotive, lighting, heat sinks, furniture, and industrial machinery. With a strong R&D team and strict quality control, ZP Aluminum ensures products meet international standards with reliable performance and aesthetic quality.

Established: 2005

Headquarters: Foshan City, Guangdong, China

Key Products:

- Custom aluminum extrusions for construction, electronics, automotive, and industrial applications

- Aluminum die casting and sand casting components

- Precision CNC machined aluminum and other metal parts

- Surface-treated aluminum products including anodized, powder-coated, and electrophoretic coated items

Technical Capabilities:

- Aluminum extrusion lines (600–10,000 tons) with anodizing and powder coating

- Die casting and sand casting of aluminum parts

- Precision CNC machining, laser cutting, punching, bending, and welding

- OEM/ODM and co-design services for customized solutions

- ISO 9001:2015 and SGS certified quality management system

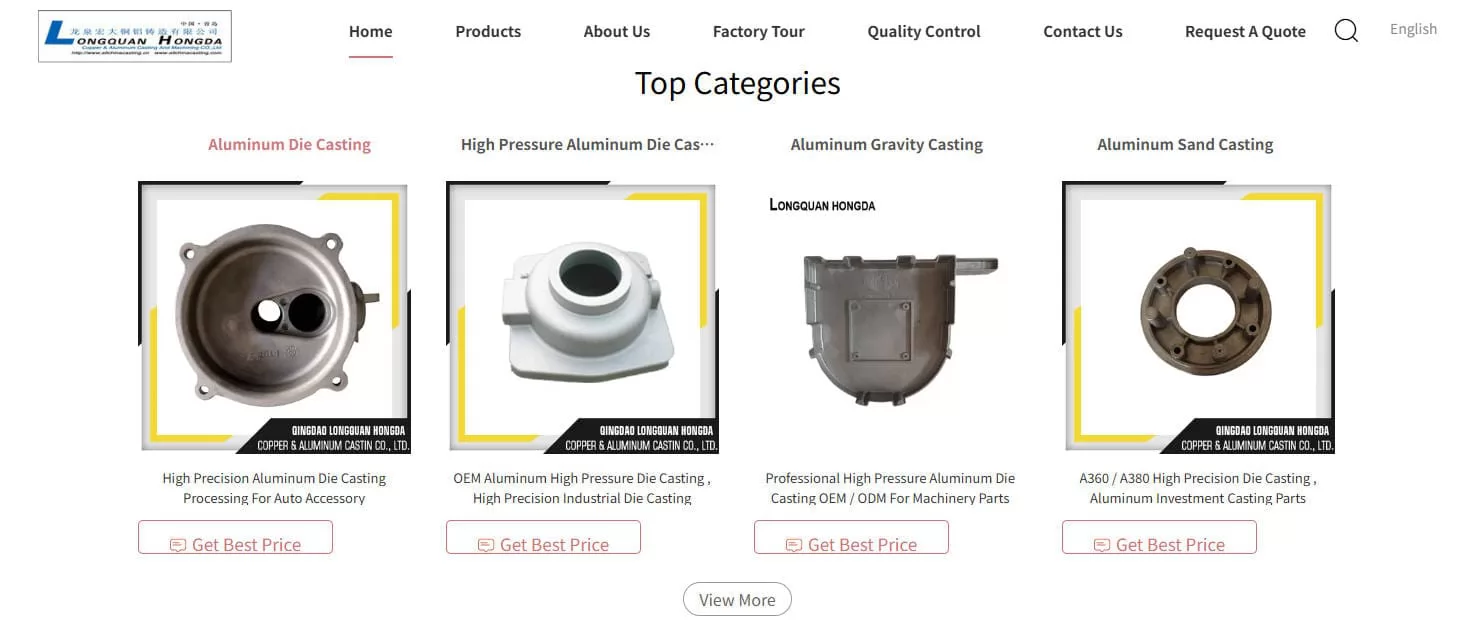

7. Qingdao Longquan Hongda Copper & Aluminum Casting

Introduction:

Established in 1978, Qingdao Longquan Hongda Copper & Aluminum Casting Co., Ltd. is a leading manufacturer specializing in copper and aluminum casting, mold production, and precision machinery processing. Located in Jiaozhou, Qingdao, China, the company covers 28,000 m² with 8,000 m² of building area and employs 160 staff, including 60 skilled technicians. Hongda integrates various casting technologies such as free sand casting, free metallic casting, gravity casting, low-pressure casting, and die casting to produce high-quality components for diverse industries worldwide.

The company possesses a complete range of equipment, including electric coreless furnaces, roller sand mixers, hot-box core shooters, air plasma cutting machines, low-pressure casters, molding machines, and precision cold chamber die casting machines. Hongda manufactures both casting molds and finished products according to customer requirements, with CNC machining centers, lathes, drilling machines, and milling machines ensuring precision and quality. Its products are exported to Italy, the USA, the UK, Canada, Japan, South Korea, and other countries.

Established: 1978

Headquarters: Jiaozhou, Qingdao, Shandong, China

Key Products:

- Copper and aluminum castings

- High-pressure die casting components

- Gravity casting and sand casting parts

- Custom molds for casting and machinery processing

- Precision CNC machined components

Technical Capabilities:

- Free sand casting and metallic mold casting

- Gravity casting, low-pressure casting, and mechanism die casting

- Full range of precision machinery processing including CNC machining, milling, and turning

- In-house mold design and manufacturing (wood type, metal type, die casting molds)

- ISO 9001 certified quality management system ensuring consistent product quality

8. Minghe

Introduction:

Founded in 2003, Dongguan Minghe Die Casting Company is a professional manufacturer specializing in high-precision die casting services and parts development. Located in Humen Town, Dongguan, China, the company covers a 30,000 m² manufacturing plant and employs around 200 engineers and support staff. Minghe provides one-stop services including die casting, CNC machining, mold making, and surface treatment for aluminum, zinc, and magnesium alloys. Their production equipment ranges from 180-ton hot chamber to 3000-ton cold chamber die casting machines, along with advanced finishing and inspection facilities.

Minghe has developed strong expertise in thin-wall and complex die castings, serving industries such as automotive, machinery, robotics, LED heat sinks, telecom, engine components, and electronics. The company emphasizes research and development, holding more than 14 patents and implementing full quality inspection procedures under ISO 9001:2015 and IATF16949 standards.

Established: 2003

Headquarters: Humen Town, Dongguan, China

Key Products:

- Aluminum, zinc, and magnesium die cast parts

- CNC machined components and assemblies

- Custom molds and tooling

- Surface treated components (powder coating, liquid painting, deburring)

Technical Capabilities:

- Hot chamber and cold chamber die casting from 180T to 3000T

- Mold design, manufacturing, polishing, and testing

- CNC machining, drilling, tapping, friction welding, and trimming

- Full quality assurance with CMM inspection

- Turnkey service including assembly, packaging, and shipping

9. OEFORM

Introduction:

Established in 2003, OEFORM is a leading die casting manufacturer based in Dongguan, China, specializing in high-precision aluminum, zinc, and magnesium alloy castings. The company combines over 20 years of expertise with state-of-the-art mold design and precision die casting equipment. OEFORM offers comprehensive services including high-pressure die casting, gravity die casting, custom mold design, CNC machining, and post-processing treatments such as anodizing and powder coating.

OEFORM serves global industries including automotive, aerospace, electronics, and industrial machinery. The company emphasizes strict quality control with ISO 9001:2015 and IATF 16949 certifications, advanced defect detection systems, and precision machining capabilities up to ±0.02mm tolerance. With an experienced team of engineers and modern facilities, OEFORM ensures consistent, reliable, and high-performance die casting solutions for complex parts and large production volumes.

Established: 2003

Headquarters: Dongguan, China

Key Products:

- Aluminum die cast components (ADC12, A380, A356 alloys)

- Zinc die cast parts (Zamak 3 & Zamak 5)

- Magnesium die cast components for lightweight applications

- Custom die casting molds and tooling

- CNC machined and surface-treated parts (anodizing, powder coating)

Technical Capabilities:

- High-pressure die casting with ±0.02mm tolerance

- Gravity die casting for radiator and automotive housings

- 5-axis CNC machining for precision finishing

- Advanced quality assurance including CMM inspection and X-ray detection

- Full turnkey solutions from mold design to assembly and delivery

10. INNOVAW

Introduction:

Founded in 1998, INNOVAW is a leading manufacturer and global supplier of aluminum and zinc castings, CNC machined components, and complete metal solutions. Headquartered in Ningbo, China, the company specializes in high-precision die casting, low-pressure casting, gravity casting, investment casting, sand casting, and CNC machining for a wide range of industrial applications. With over 20 years of expertise, INNOVAW provides end-to-end solutions from design and rapid prototyping to mass production and surface finishing.

INNOVAW serves diverse industries including automotive, energy, LED lighting, marine, telecom, and medical devices. The company combines advanced manufacturing capabilities with a strong engineering team to ensure reliable, high-quality, and cost-effective production. INNOVAW has established a global presence with export operations to over 40 countries and partnerships with 200+ clients worldwide.

Established: 1998

Headquarters: Ningbo, China

Key Products:

- Aluminum and zinc die castings

- CNC machined components

- Rapid prototyping solutions

- Custom enclosures and housings for industrial applications

Technical Capabilities:

- High-precision die casting, low-pressure casting, gravity casting, investment casting, and sand casting

- CNC machining with DMG Mori, MAZAK, BROTHER, and HASS machines

- DFM analysis, 3D mold design, and mold flow simulation

- Surface finishing including sandblasting, painting, powder coating, anodizing, and plating (ROHS and REACH compliant)

Aluminium Casting Foundries and Companies in China

China’s aluminium casting industry has rapidly gained a strong international reputation thanks to its combination of efficiency, high quality, and technical innovation. Here’s why global businesses increasingly turn to Chinese foundries:

1. Competitive Production Costs

Chinese aluminium casting companies are able to deliver top-quality components at very competitive prices. With easy access to raw materials, modern manufacturing facilities, and skilled labor, these foundries provide cost-efficient solutions without compromising standards.

2. Advanced Precision and Custom Solutions

These foundries are capable of producing highly precise and fully customizable aluminium castings. From simple parts to complex, intricate components for automotive, aerospace, electronics, and machinery applications, they can meet a wide range of technical requirements.

3. Broad Product Selection

Chinese aluminium casting companies produce everything from small mechanical parts and housings to large-scale industrial components. This diversity makes them a convenient one-stop provider for companies requiring dependable casting services.

Market Outlook for China Aluminium Casting in 2026

The future of China’s aluminium casting sector looks promising. Industry analysts predict steady growth driven by rising demand in automotive, construction, and electronic applications. Key factors fueling this growth include:

- Government support for infrastructure and industrial development

- Increased use of lightweight aluminium parts in vehicles and machinery

- Technological improvements in casting, machining, and finishing processes

Potential challenges include fluctuations in raw material costs and international competition, but overall, the industry is expected to maintain positive growth.

Pricing for Aluminium Castings in China

Prices for aluminium castings in China vary widely depending on part size, complexity, alloy type, and finishing methods. Typical ranges include:

- Standard small components: $3–$12 per piece

- Large or intricate castings: $20–$60 per piece, based on precision and secondary processing

- Additional finishing (anodizing, powder coating, polishing): +10–30%

Factors that affect pricing include:

- Alloy selection and tolerance requirements

- Mold complexity and production volume

- Post-processing and surface treatment

- Packaging and international shipping costs

To get accurate pricing, it is best to provide manufacturers with detailed specifications and order quantities.

Frequently Asked Questions about China Aluminium Casting Foundries

1. Why partner with Chinese aluminium casting companies?

They offer a combination of affordable pricing, reliable quality, and advanced production capabilities. Chinese foundries have extensive experience serving both domestic and international clients.

2. How can I identify a trustworthy aluminium casting supplier in China?

Look for companies that have:

- Years of experience and a solid track record

- ISO or equivalent quality certifications

- Positive customer feedback and references

- A portfolio showcasing completed projects

- Engineering and post-production support

3. Are aluminium castings customizable?

Yes. Foundries in China can produce castings tailored to your specifications, including size, weight, alloy type, and surface finish.

4. Can I order in small batches as well as bulk?

Absolutely. Most foundries offer flexible minimum order quantities, making them suitable for prototypes, small production runs, or mass manufacturing.

5. How long does production typically take?

Lead time depends on part complexity and order size. Standard components can usually be produced within a few weeks, while more complex parts may require additional time for mold making and finishing.

6. Are Chinese aluminium castings compliant with international standards?

Most reputable suppliers adhere to ISO and other international quality standards. Always verify compliance for critical applications in your target market.

7. Can aluminium castings be exported from China?

Yes. Many companies have extensive experience exporting worldwide and can assist with logistics, customs clearance, and secure packaging.

Conclusion

The Chinese aluminum casting industry has become a global hub for high-quality and precision metal casting solutions, offering diverse processes such as die casting, gravity casting, low-pressure casting, sand casting, and CNC machining. Many established manufacturers now serve a broad spectrum of industries—including automotive, electronics, energy, medical devices, and industrial machinery—providing both OEM and custom-engineered metal components. With increasing demand for lighter materials, tighter tolerances, and cost-effective production, companies are focusing on integrated capabilities such as in-house tooling, surface finishing, rapid prototyping, and strict international quality control standards.

As the market becomes more competitive, businesses looking for aluminum casting suppliers are no longer satisfied with basic manufacturing alone. They need partners who can offer engineering guidance, product optimization, fast turnaround, and truly end-to-end solutions—from design and mold simulation to mass production and global delivery. Reliability, innovation, and quality consistency have become key factors in selecting a long-term casting partner.

This is where INNOVAW stands out. With strong expertise in aluminum and zinc casting, CNC machining, mold design, and rapid prototyping, Innovaw provides complete solutions tailored to global client needs. Backed by advanced manufacturing capabilities, engineering excellence, and a commitment to quality, Innovaw offers not just parts—but optimized, value-driven manufacturing solutions that help customers bring products to market faster, smarter, and with confidence.

-

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World -

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China -

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

-

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China -

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World -

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China -

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China