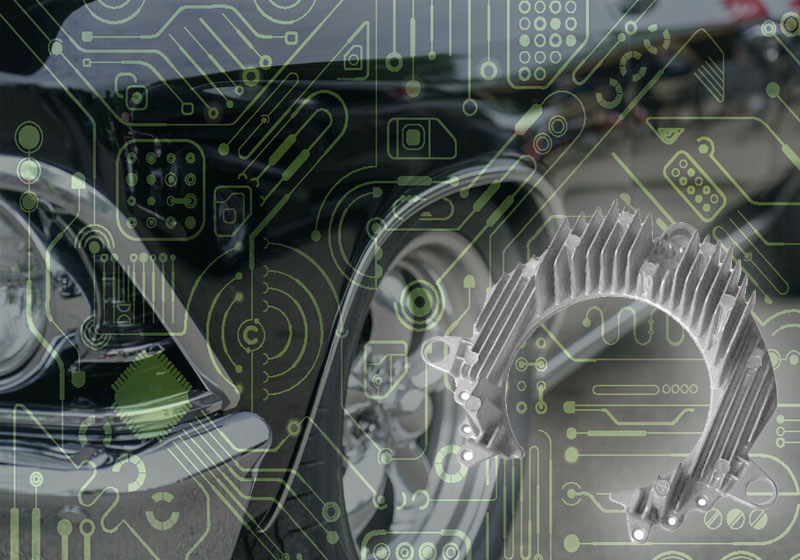

Automotive Electronic Heat Sink Development Case

Project Brief

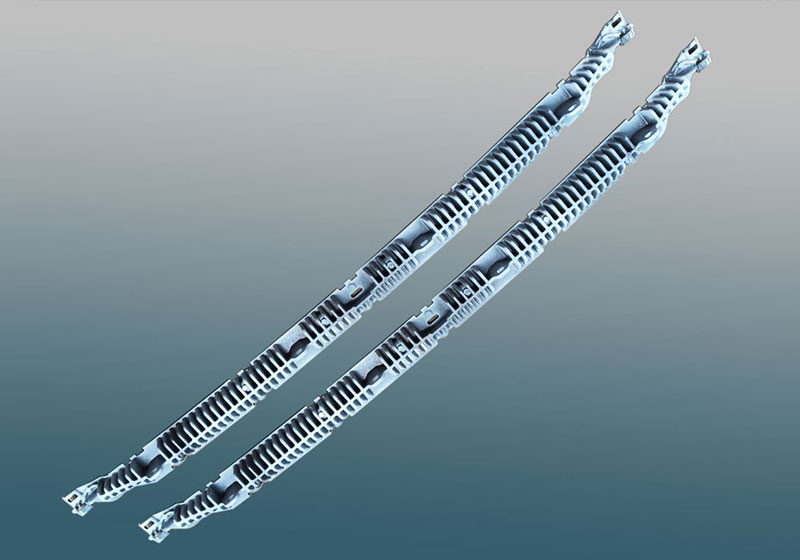

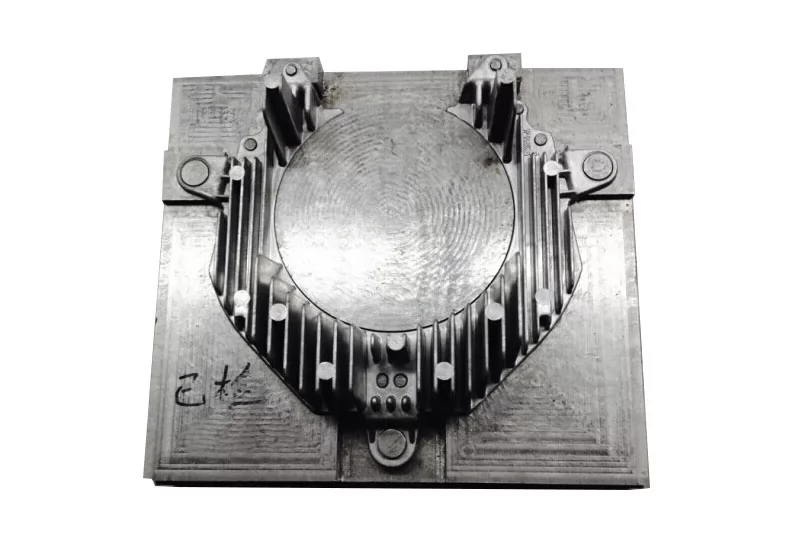

This is a custom-designed automotive electronic heat sink featuring a ring structure with a large number of vertically arranged cooling fins on a planar surface. It serves multiple functions including component protection, interfacing with different structures, as well as providing support and heat dissipation.

1. Product Standards & Requirements: Material: A380; General dimensional tolerance grade: ISO 2768-mK; Local flatness: 0.3; Flawless appearance; Surface roughness: Ra6.3µm; No internal defects. PPAP approval must be completed and passed before formal mass production.

2. Product Challenges: Cooling fins of varying heights are distributed on an irregular plane, making the product prone to deformation. The ribs are thin, with the narrowest point being 1.3mm in width and 32mm in depth, posing a risk of mold heat checking.

Risk Keywords: Complex structure, Deformation, Cold shut, Heat checking.

The overall project presented a significant challenge, particularly testing our capabilities in mold design and quality control.

Development Process

We formed a project development team comprising mold designers, casting engineers, measurement engineers, quality engineers, and sales. The team applied the core methodology of the internationally advanced IATF 16949 standard - Advanced Product Quality Planning (APQP), entering a comprehensive product development process focused on quality.

We began with DFM analysis to optimize certain structural details for enhanced manufacturability, establishing mutually agreed-upon technical specifications and quality standards with the customer.

Considering the application environment and performance requirements of this automotive electronic heat sink, the material was confirmed as A380. Based on the material properties and the core design elements of the product, the process route of high-pressure die casting (HPDC) was ultimately determined, balancing technical feasibility, quality stability, and cost control.

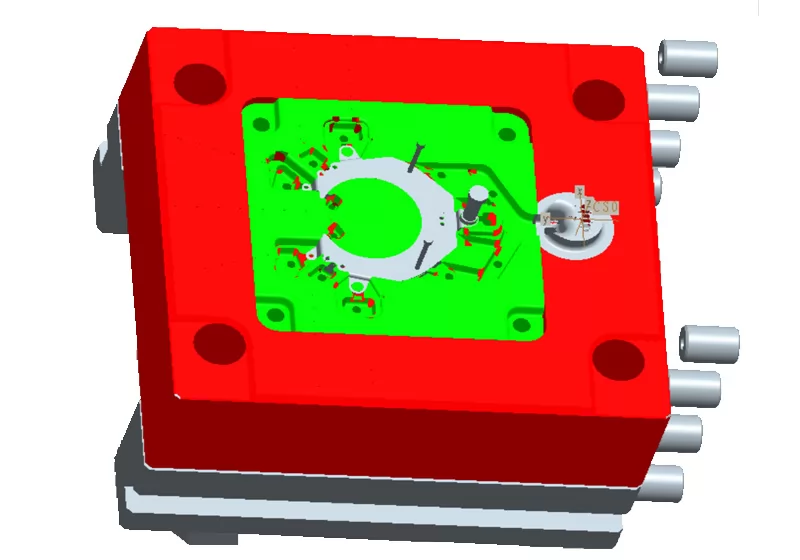

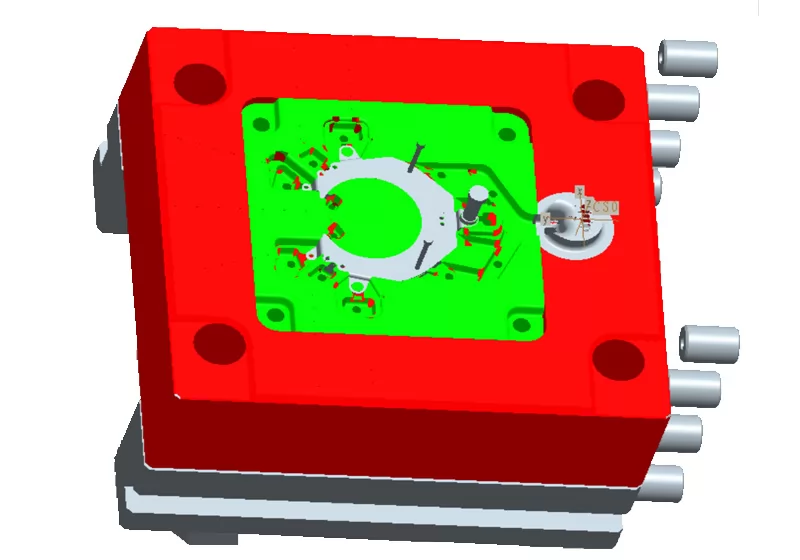

Subsequently, technical engineers performed mold simulation and mold flow analysis to predict and optimize various challenges and process parameters. A die-casting simulation analysis report was provided to the customer, and preliminary Process Flow Charts and Control Plans were established.

Finally, the plan was gradually validated, and issues were identified and resolved in the subsequent practical stages.

Practice Validation & Optimization

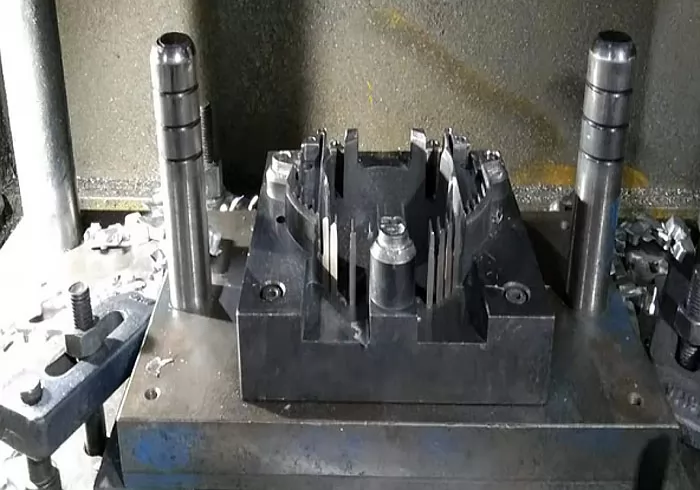

Marked by the commencement of mold manufacturing, the project entered the actual manufacturing phase. Our company proceeded according to the initial Process Flow Chart, established the Control Plan, and applied FMEA tools for risk analysis and assessment of various potential failure modes. The main key issues encountered during the actual manufacturing process were as follows:

A. Mold Optimization

Considering the characteristics and challenges of this product, mold engineers had already taken full account during the initial mold design to anticipated problems. However, during actual trial molds, some issues inevitably arose, such as cold shuts, deformation, and deviations in hole position accuracy. The development team identified the root causes for these problems and ultimately resolved them effectively through mold optimization schemes and by refining relevant parameter settings during the die-casting process.

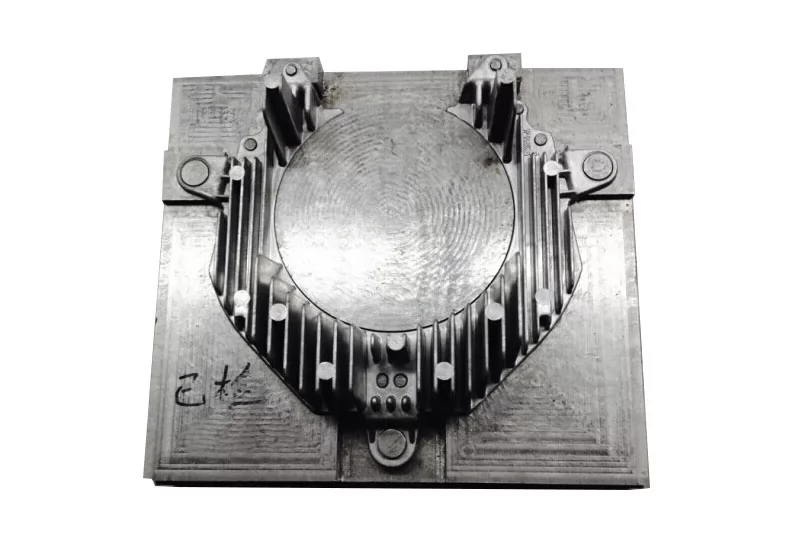

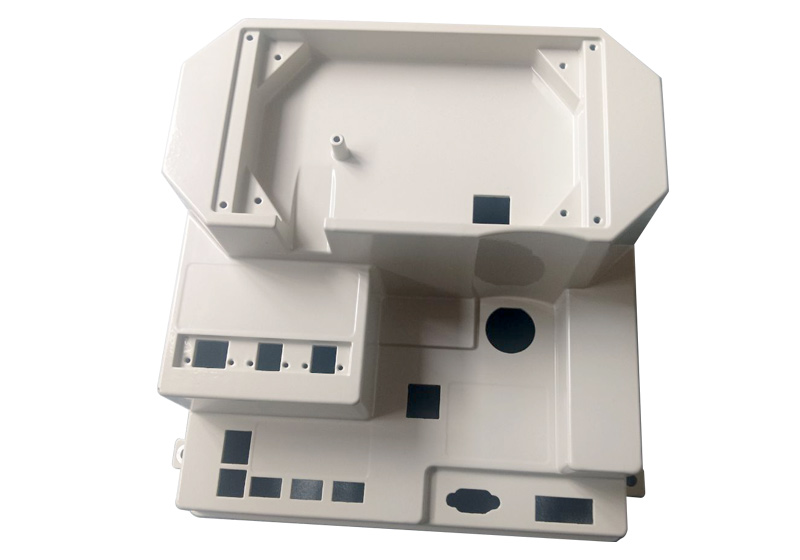

B. Dedicated Trimming Die Solves Flatness Issues

The irregular design of this heat sink casting and its high flatness requirements also caused difficulties in subsequent trimming and deburring operations. During the sampling stage, engineers identified issues like deformation and burrs during product inspection. Traditional methods for resolving these issues were relatively time-consuming, labor-intensive, and inefficient. To address this, besides implementing numerous optimizations in the mold design, the project team also developed a dedicated trimming die for the trimming process. This die removes the flash from the periphery and all holes in one step. It was paired with a dedicated comprehensive inspection gauge for targeted verification. These measures allowed for the simultaneous validation of key points like flatness, hole position offset, and trimming residual height, significantly improving efficiency.

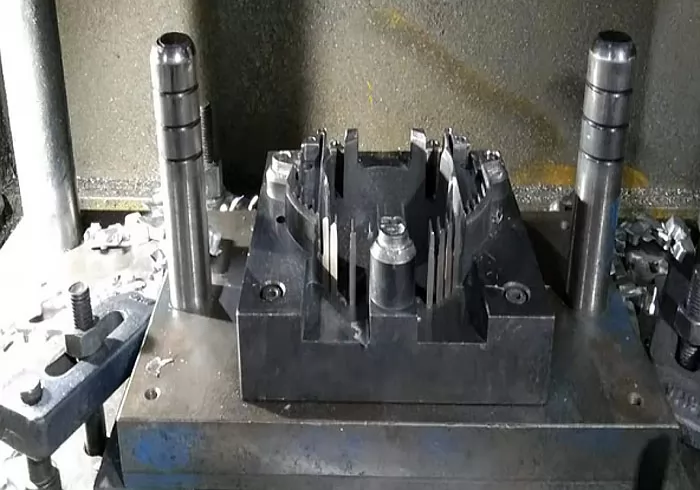

Customized Specialized Trimming Dies

Customized Specialized Inspection Fixtures

C. Other Minor Issues Encountered Practically

During the actual sampling process, the following additional issues were discovered:

1. M4 threaded holes on some samples could not be tapped; the reason was damaged taps not being replaced promptly.

2. Occasional surface mildew on heat sink fins; the cause was improper warehouse storage.

3. Defective local chamfers on some products; the reason was the lack of guide and positioning devices in the trimming die, causing workers to misalign the product during trimming, leading to defects.

Addressing these quality issues, the team utilized extensive aluminum die casting development experience, conducting detailed investigations and careful verification to resolve them one by one. The discovery, causes, countermeasures, and results for these issues were documented in SPC, FMEA, Control Plans, Work Instructions, and other documents to ensure the same problems would not recur.

Quality Control

The entire development process was a systematic procedure of identifying and controlling quality risks while continuously optimizing the process. The dedicated automotive heat sink project team leveraged rich experience and solid technology to conduct technical reviews and repeated verification at every process step, systematically identifying and tackling potential risk points. The team's quality engineers strictly adhered to the IATF 16949 quality system, implementing the full APQP process requirements to achieve full-process quality control. Throughout the process, various standardized documents and practices such as FMEA, SPC, MSA, and Control Plans were established and executed to prevent potential process risks, quality risks, and control quality variation. Finally, PPAP documentation was established and approved by the customer, laying a solid foundation for formal mass production.

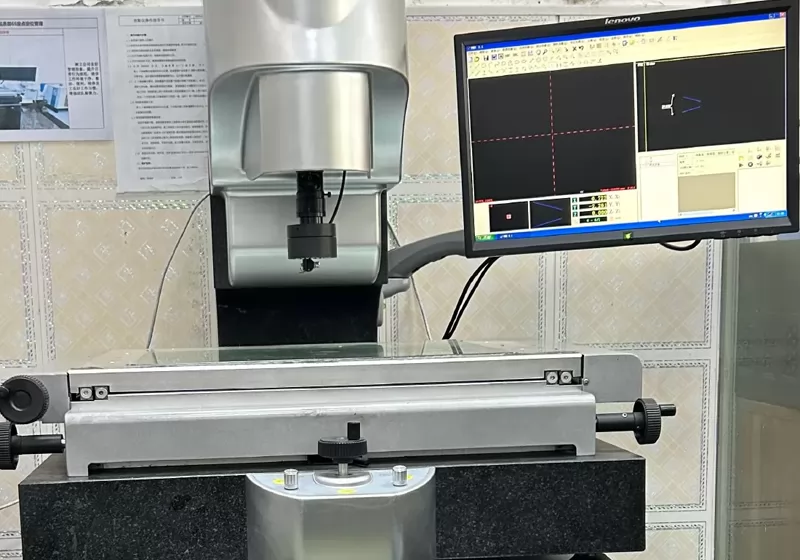

The process included first-article inspection, in-process inspection, and outgoing inspection, establishing complete inspection data retention to ensure all quality data is traceable and verifiable.

Results and Evaluation

Finished Product Metrics:

1. Dimensional Accuracy: Including flatness and over 50 dimensional standards, all met.

2. Surface Quality: Met standards.

3. PPAP completed and approved by the customer.

The development of this aluminum die-cast automotive electronic heat sink component by Innovaw, with its relatively high technical difficulty and stringent comprehensive performance requirements, served as a test of the manufacturer's overall capabilities. Relying on profound expertise in high-pressure die casting, precision CNC machining capabilities, and an excellent quality management system consistently implemented throughout the process, we successfully overcame the challenges and delivered a high-quality product that met and even exceeded customer expectations. This fully demonstrates our casting development team's professional capability for systematic problem analysis and rapid closed-loop improvement in developing complex structural components.

Production Process

Mould making→Melting→High Pressure Die Casting→Cutting the sprue and riser→Deburring→Drilling→Reaming of pin holes→Vibratory Finishing→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.