Project Brief

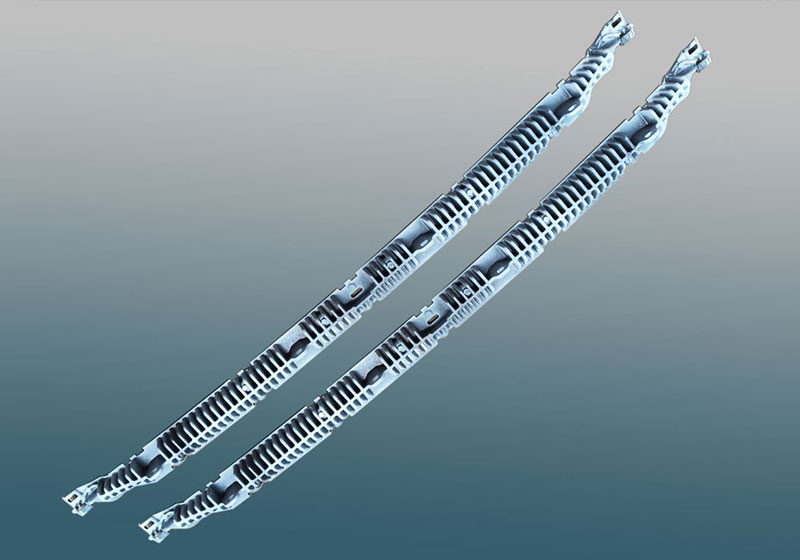

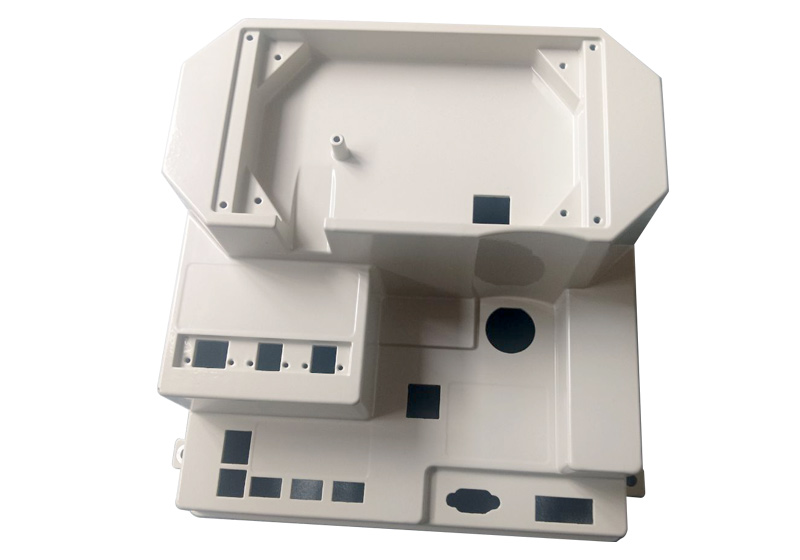

This is a custom automotive circuit heat sink casting, which performs multiple functions including heat dissipation, component protection, mechanical support, and installation.

1. Product Standards & Requirements: Material: EN AC46000; full-size tolerance grade: ISO 2768-mk; Minimum dimensional tolerance is ±0.05mm; surface free of defects (surface roughness Ra6.3µm); internal free of defects. Before official mass production, PPAP approval must be completed and passed.

2. Product Challenges: Complex structure with multiple stepped levels, posing high demands on mold design; deburring is complicated; machining holes are located in different orientations, making the structure extremely difficult to process.

Risk Keywords: complex structure, step processing, fracture, cold shut, incomplete filling.

Overall, this project presents a certain level of difficulty, particularly testing our mold design capability and quality control capability.

Development Process

1. Following the APQP (Advanced Product Quality Planning) process, we established a project development team consisting of mold designers, casting engineers, machining engineers, measurement engineers, quality engineers, and sales staff, entering a full product development process with quality at the core.

2. Through DFM analysis, certain structural details of the product were optimized to improve manufacturability, and jointly recognized technical specifications and quality standards were established with the customer.

3. Based on the material properties, and integrating the core design elements of this product, the final process route was determined as high-pressure die casting + CNC precision machining, from the perspectives of technical feasibility, quality stability, and cost control.

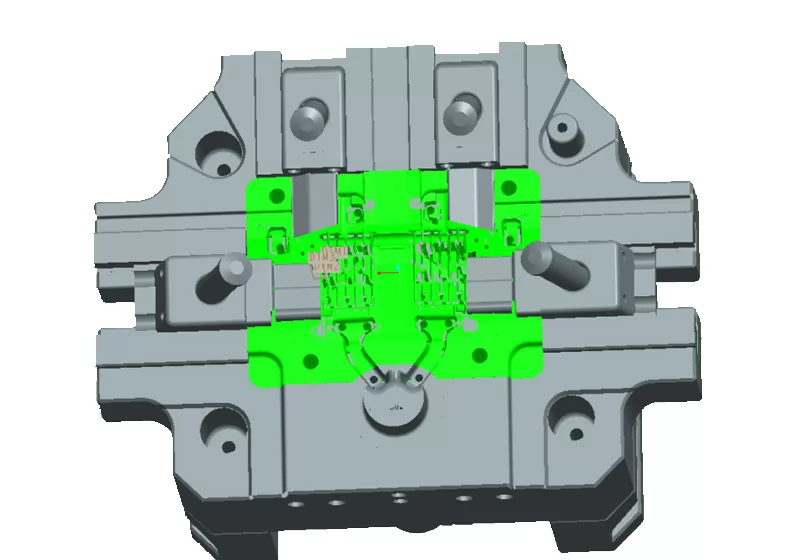

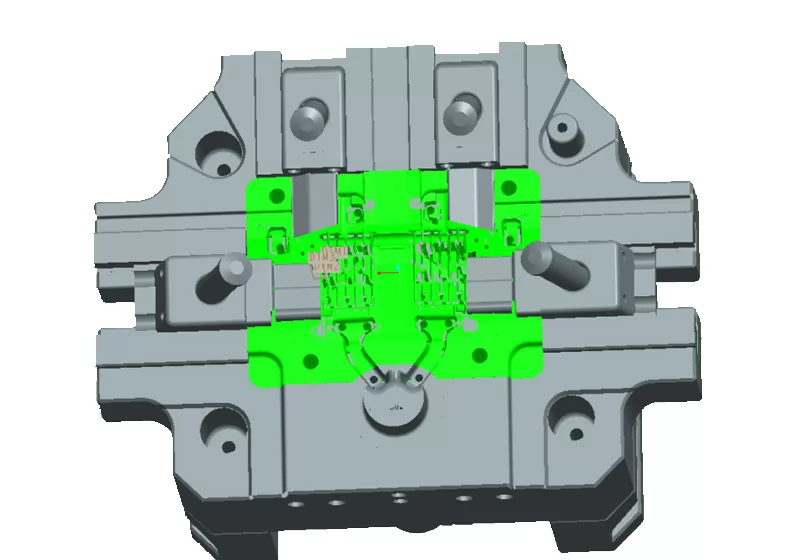

4. Technical engineers conducted mold scheme reviews, mold design and simulation, mold flow analysis, predicting and optimizing various challenges and process parameters, and provided die-casting simulation analysis reports to the customer.

5. During subsequent production processes, the solutions were gradually validated, and problems were discovered and resolved. Key cases include:

• During trial molding, incomplete die casting was found, which was solved by modifying the mold gate and adjusting die-casting parameters.

• Deburring after die casting was difficult; both robotic and manual deburring solutions faced challenges, so a dedicated trimming die was developed to solve the issue.

• Due to the product structure, machining was difficult. The development team designed a dedicated machine integration solution, adopting an assembly-line process to overcome the machining challenge.

Throughout the development process, FMEA, SPC, MSA, process control plans, and other standard documents were established. Finally, PPAP documentation was completed and approved by the customer.

This automotive circuit heat sink aluminum casting not only demonstrates excellent performance and precision, but also features good thermal conductivity, corrosion resistance, lightweight properties, strong protective capabilities, and ease of installation and maintenance. The finished product fully met the customer’s design objectives, providing a higher-performance and more reliable solution for this type of automotive component design.

Production Process

Mould making→Melting→High Pressure Die Casting→Cutting the sprue and riser→Deburring→Drilling→Reaming of pin holes→Vibratory Finishing→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.

Share your thoughts

Showing

6

of

0

reviews