Innovaw Aluminum Castings for the Automotive Industry

In 2002, we produced our first aluminum automotive part for a customer - a heat sink lampshade for a construction truck. Since then, Innovaw has focused on developing products for the automotive industry. In 2015, Innovaw received the IATF 16949 certification, which signifies that Innovaw strictly follows the internationally advanced quality management system as the standard for day-to-day production management. We are committed to lean manufacturing and continuous improvement to be able to meet the changing needs of the automotive industry.

We develop and produce aluminum castings according to the different requirements of different automotive parts by applying aluminum high-pressure die casting, low-pressure die casting, gravity casting, investment casting, and cnc machining processes, and we have won the trust of our customers with our highly reliable and consistent quality and customer-focused services. We maintain long-term relationships with automotive industry customers with stable quality control, and are regarded as a trusted partner by our customers to meet their needs for high-precision and performance-critical automotive parts.

Automotive parts occupy an important position in Innovaw's product lineup and are the leading products with the largest share. All of our automotive parts are developed according to customers' drawing requirements and are mainly used in commercial vehicles, including heavy trucks, light trucks, pickup trucks, trailers, semi-trailers, buses, and specialty vehicles.

The current situation of aluminum castings in the automotive industry

Because of the product characteristics of aluminum castings, the products produced by aluminum casting process are suitable for application in the axle and suspension of automobiles, towing devices, hydraulic devices, shock absorption systems, transmission systems, carriages, dumping devices, engine accessories, lighting and other parts.

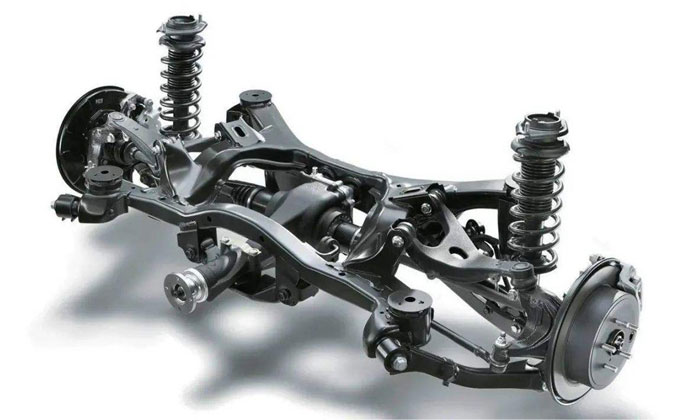

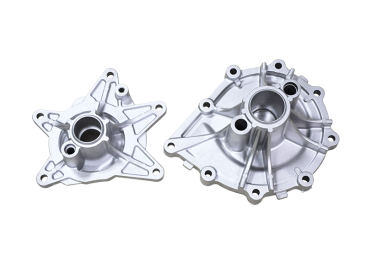

Arm, Knuckle, Subframe, Wheel Hub, Brake Caliper, etc

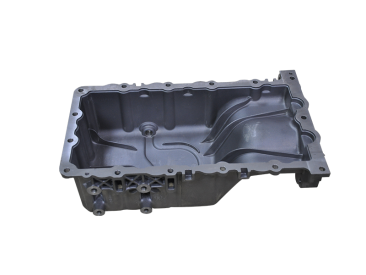

Cylinder Block, Cylinder Head, Intake/Exhaust Manifold, Oil Pan, Crankcase Housing, etc

Shock Absorber Housing, Suspension Link, etc

Headlight Housing, Heat Sink Bracket

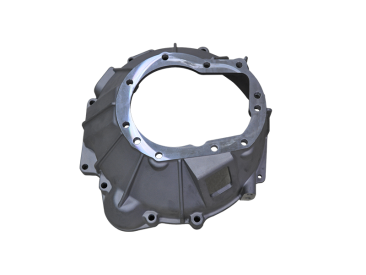

Transmission Case, Clutch Housing, Differential Case, etc

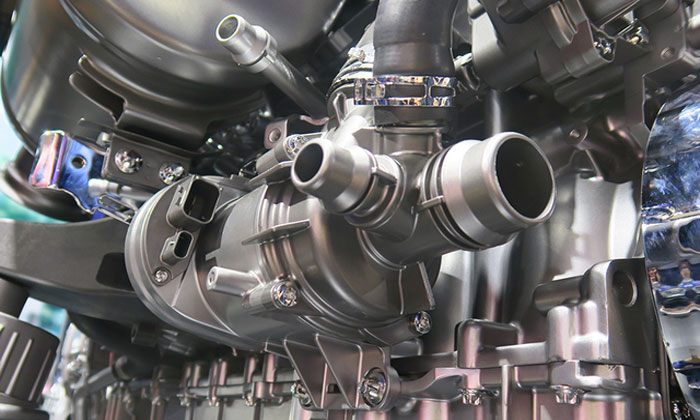

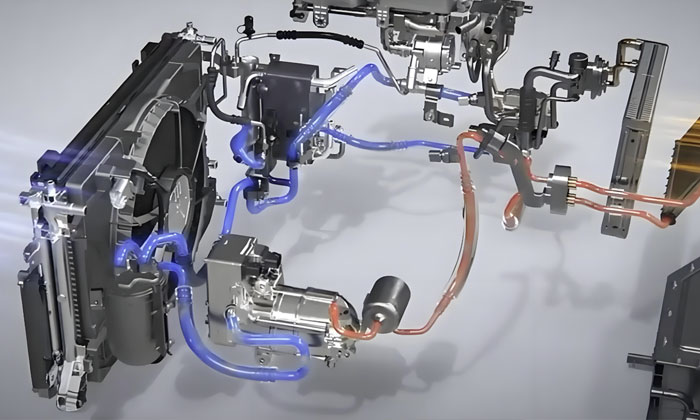

Water pump housing, Radiator Housing、Heat exchanger end caps, Compressor Housing, etc

Automotive Aluminum Casting Cases

The significance of the application of aluminum casting for the automotive industry

Aluminum casting for the automotive manufacturing industry, has a significant superiority. The main performance in.

- Light weight, improve fuel economy

- Good strength and durability

- Strong corrosion resistance, long life

- Good heat dissipation performance

- High plasticity, suitable for complex design

- Environmentally friendly and recyclable

Aluminum castings account for an increasing proportion of auto parts in a car. At the same time, with the accelerated transformation of the global automotive industry to lightweight, energy saving and emission reduction, electrification, the role of aluminum alloy castings in the design and manufacture of the whole vehicle has become more and more prominent.

The application of aluminum castings has brought positive significance in many aspects:

1. Realize automobile lightweight, improve energy efficiency and range

The main way to reduce fuel consumption is to realize the weight reduction of the whole vehicle, while the density of aluminum is only 1/3 of that of steel, and under the premise of meeting the requirements of structural strength, replacing the traditional iron and steel parts with aluminum can significantly reduce the weight of the vehicle.

2. Improve thermal management performance, enhance mechanical efficiency

Aluminum has excellent thermal conductivity and heat dissipation, especially for engines, water pumps, motor shells and other high-heat components, which helps to control the temperature rise and extend the life of parts. Especially in new energy vehicles, motor, electronic control and battery systems require higher thermal management, and aluminum castings are one of the key material choices.

3. Support integrated design of parts and simplify assembly structure

Aluminum alloy casting can realize one-piece molding of complex structures, enhance the structural integration of parts, reduce welding or assembly processes, and improve manufacturing efficiency.

4. Enhance the safety and handling performance of the whole vehicle

Aluminum castings for suspension systems, steering knuckles and other quality components can effectively reduce the weight of accessories, improve the dynamic response of the car and handling stability. Aluminum alloy energy-absorbing structure has good controllable deformation characteristics, which can improve crash safety and energy-absorbing efficiency.

5. Promote green manufacturing and recycling

Aluminum has good recyclability and renewability, and a high proportion of aluminum castings can be recycled and reused after service life, which is in line with the “green” goal of the automotive industry. Compared with steel, aluminum processing has lower energy consumption and carbon emissions, which helps realize green manufacturing.

Aluminum casting is not only a choice of material and process, but also a key part of the modern automotive industry in technological upgrading, green transformation and performance improvement.

Innovaw Aluminum Casting Solutions for the Automotive Industry

As the automotive industry continues to develop in the direction of lightweight, energy saving and environmental protection, aluminum castings have become an important alternative to traditional steel materials due to their lightweight, high strength and corrosion resistance. As a professional enterprise in the field of aluminum casting process, we provide global customers with production to delivery solutions to help the automotive industry to meet the challenges of technological upgrading.

1. In practical applications, automotive parts are characterized by complex specifications and diverse needs. From powertrain to chassis components, from structural parts to functional parts, complex geometries, strict mechanical performance requirements, and multi-functional integrated design, all put forward higher manufacturing standards for aluminum castings. Innovaw strictly follows the IATF 16949 quality management standards, and strictly implements quality management throughout the entire production process to ensure that automotive aluminum castings continue to improve in terms of dimensional accuracy, densification, strength and surface quality. We ensure that the dimensional accuracy, denseness, strength and surface quality of automotive aluminum castings are continuously improved.

2. For different types of automotive parts, different aluminum casting processes are required to fit the best solution. For example, engine block, gearbox shell and other mass production using high-pressure casting process. Suspension bracket, body connectors and other structural complexity, local stress parts, is more suitable for low-pressure casting or gravity casting. For critical parts requiring extremely high strength and toughness, some of them will also be combined with sand casting and subsequent heat treatment processes to meet the most demanding use of the environment.

Innovaw specializes in all types of aluminum casting technologies, including high-pressure casting, low-pressure casting, gravity casting and sand casting, and is able to flexibly respond to the performance requirements and process challenges of different parts.

3. In the current competitive environment, flexible inventory management of parts is one of the important core demands of customers, Innovaw responds to the needs of customers by providing efficient supply chain management services through self-developed mold design optimization, advanced production management system, and fast logistics services.

4. In response to different product development needs, Innovaw's development engineers and industry experts work closely with customers to reduce product design defects through DFM analysis, mold flow analysis and other tools, to achieve rapid realization of products from drawings to finished products.

In the future, we will continue to be driven by innovation, constantly improve process capabilities and product performance, and work with customers to create a highly efficient, green and intelligent automotive industry in the future.