APQP

APQP (Advanced Product Quality Planning) is a systematic methodology widely adopted in the automotive industry. It aims to identify and resolve potential quality issues early in the product development cycle, ensuring new products launch on schedule, meet customer requirements, and minimize risks. Its core objective is to achieve controllable product quality and continuous improvement through cross-functional collaboration and structured planning. Within quality management systems, IATF 16949 defines “what to do,” while APQP provides the “how to do it” methodology. It serves as a critical pathway for fulfilling the product development and quality planning requirements outlined in 16949.

Innovaw, as a manufacturing company with strict quality management, APQP is not just a tool, but a systematic approach to project management and quality prevention. We achieve the goal of “doing it right the first time” for every project through advance planning, risk analysis, structured development process and continuous feedback.

We have also added digital management, quality data analysis, AI-assisted FMEA and other new technologies to the APQP process to realize intelligent quality planning.

Every Innovaw employee pays close attention to the input and output of each step of product production; our products undergo strict quality checks in each process; and formal reviews are conducted at the end of each stage to ensure that quality objectives are met.

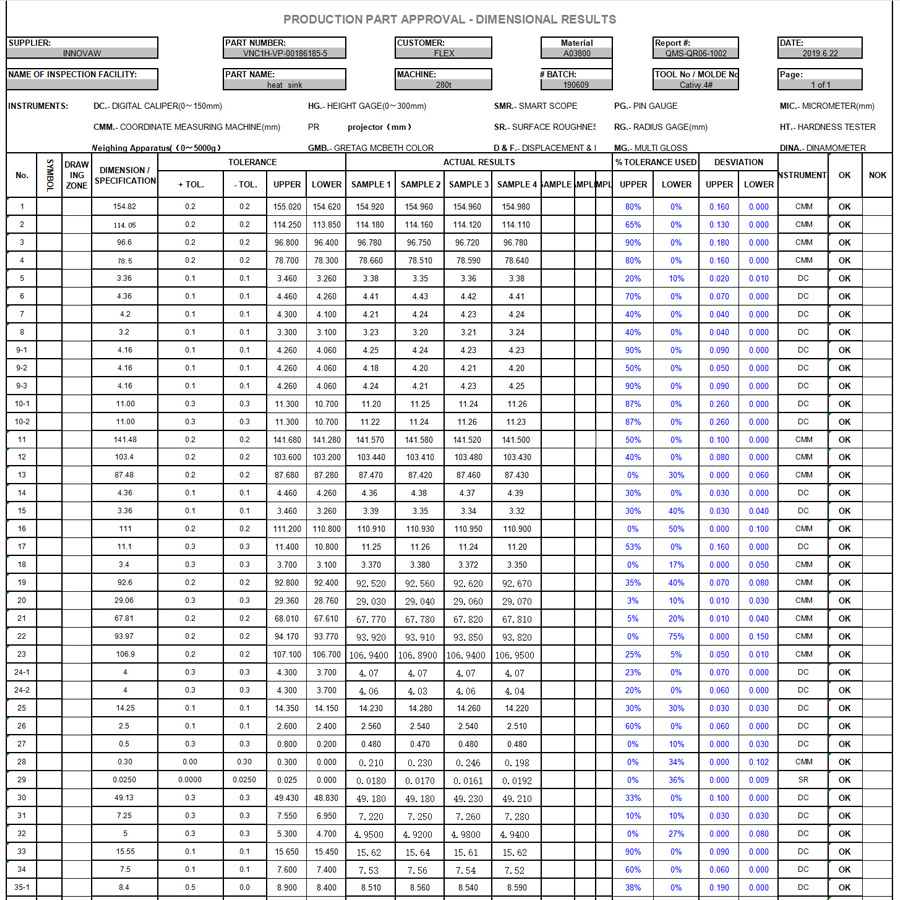

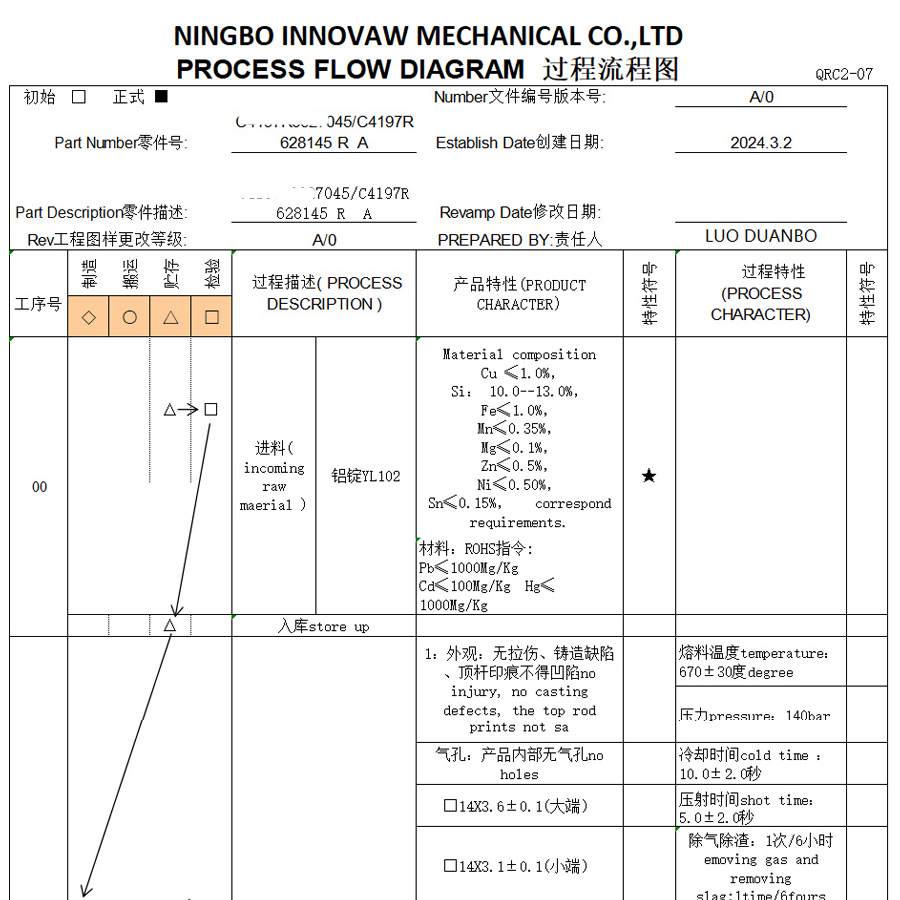

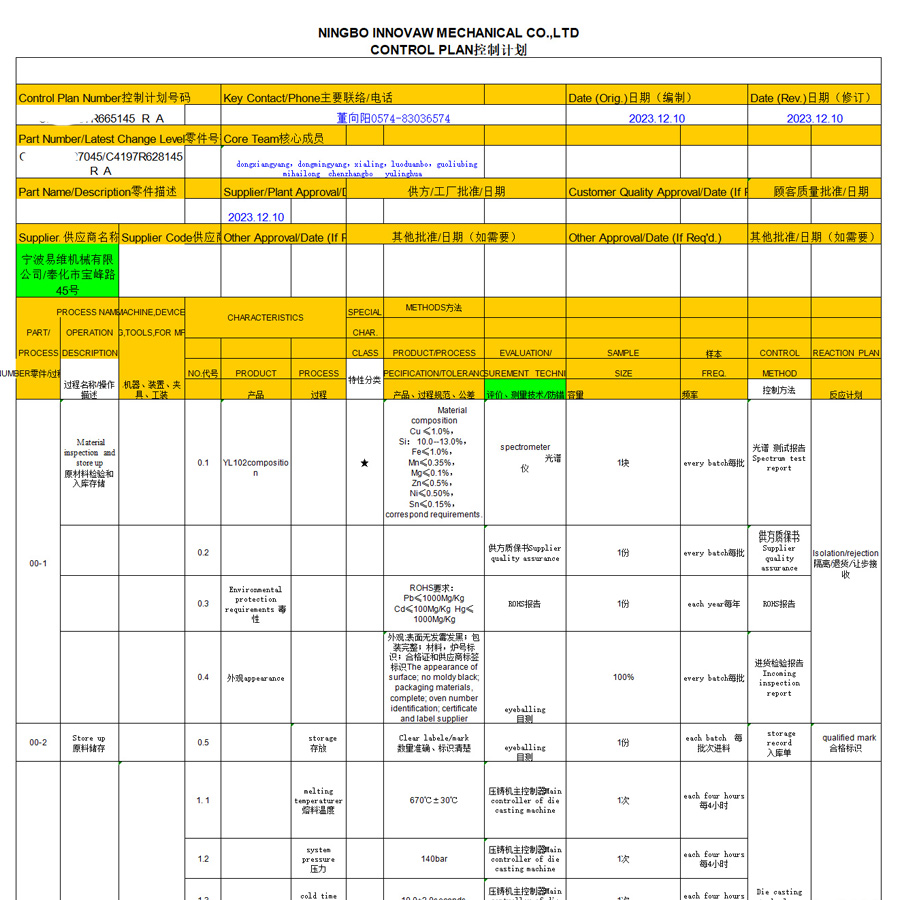

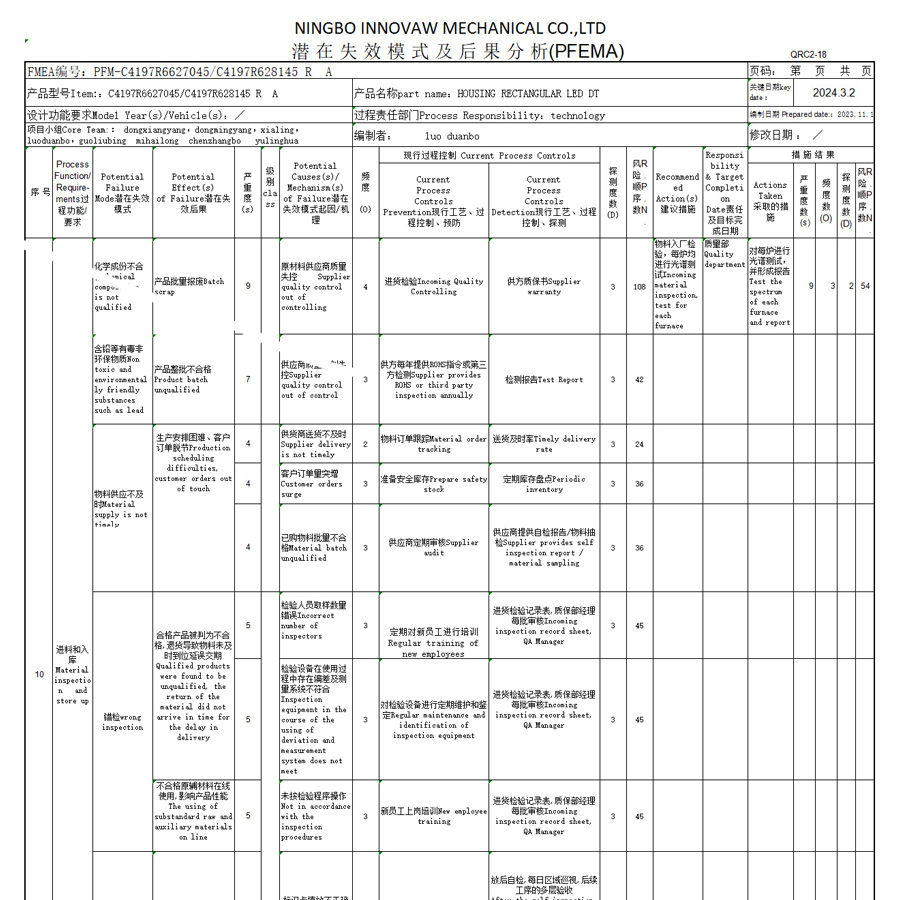

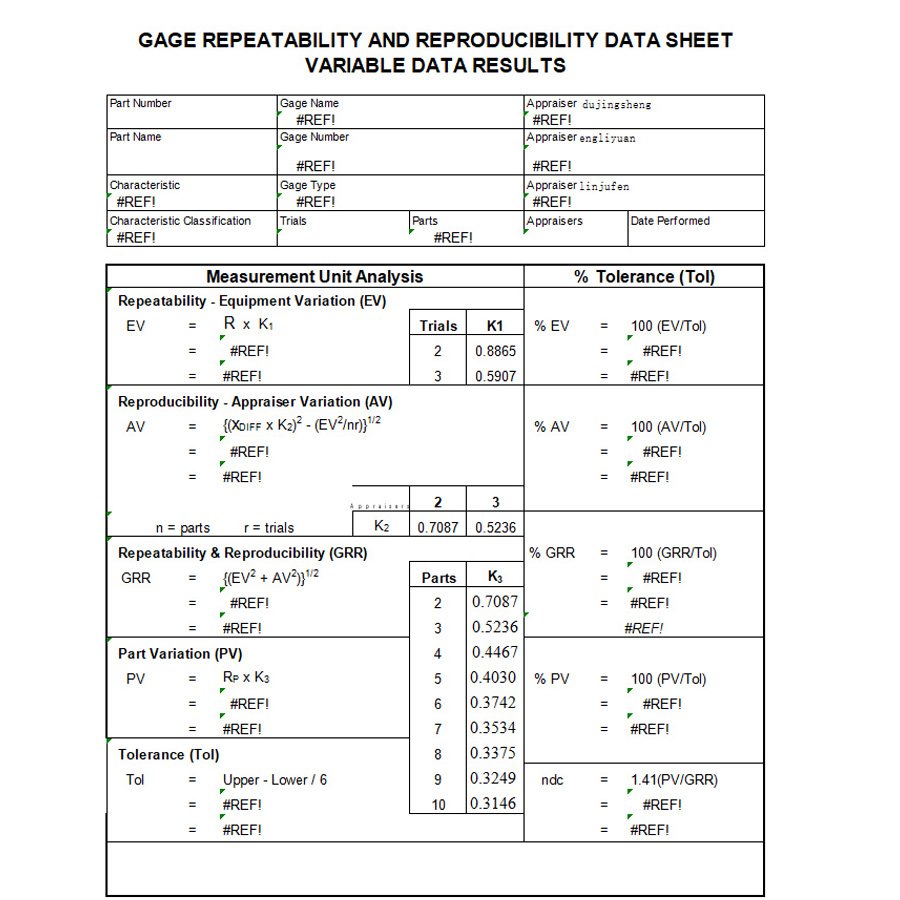

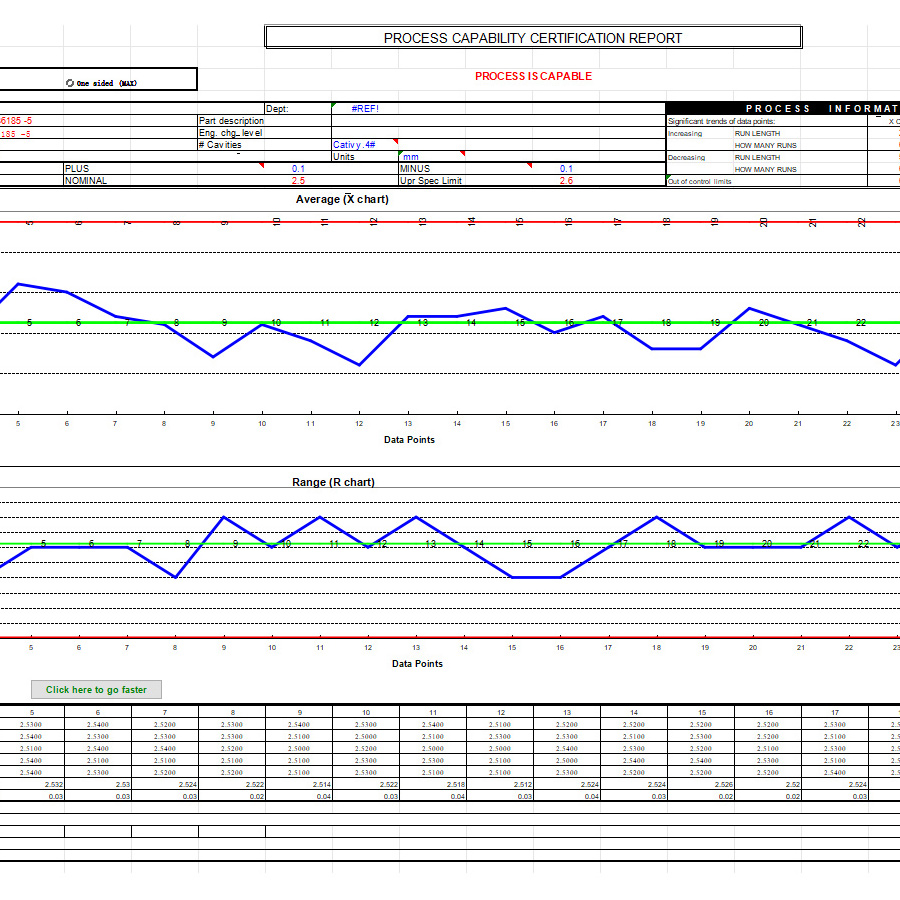

We rigorously apply APQP tools to product development, develop design specifications based on customer requirements, and use Failure Mode and Effects Analysis (FMEA) tools to identify potential risks during the design phase. Statistical Process Control (SPC) is implemented to monitor and control processes to ensure that they meet quality standards. Use Measurement System Analysis (MSA) to ensure that our measurement systems accurately measure product characteristics. Implement a Production Part Approval Program (PPAP) to verify that the manufacturing process consistently produces parts that meet the required level of quality.

Sample Quality Documents

Process Flow

Control Plan

PFEMA

MSA

Process Capability Certification Report