- Pattern Making: A pattern of the part is created, usually from wood, metal, or plastic. The pattern can be split into sections to facilitate mold assembly.

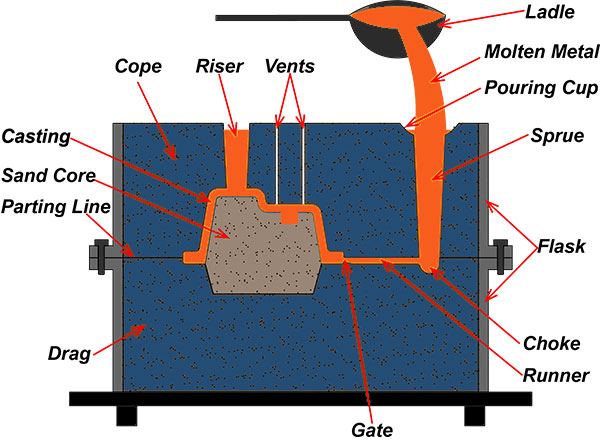

- Mold Creation: Sand mixed with a binder is packed around the pattern in a mold box. For parts with hollow sections, sand cores are placed inside the mold.

- Pattern Removal: The pattern is carefully removed, leaving a cavity in the sand shaped like the part.

- Mold Assembly: The mold halves are assembled, and the gating system (channels for metal flow) is created.

- Pouring: Molten aluminum is poured into the mold through the gating system.

- Solidification and Cooling: The metal solidifies as it cools within the sand mold.

- Shakeout and Cleaning: The mold is broken apart to remove the casting. Excess material (gates, runners, risers) is removed, and the part is cleaned.

- Finishing: The casting is inspected, and additional finishing (e.g., machining or polishing) is performed if necessary.

Sand Casting

Aluminum sand casting is a widely used metal casting process where molten aluminum is poured into a mold made of sand. The sand mold is created using a pattern, which shapes the cavity where the aluminum solidifies into the desired part. This process is highly versatile, cost-effective, and suitable for producing aluminum components with a range of sizes and complexities.

Advantages of aluminum sand casting:

- Sand Mold: Made of sand mixed with a binder to hold its shape, can be reusable (for permanent patterns) or single-use

- Versatile Geometry: Supports simple to moderately complex shapes, including internal cavities (using sand cores)

- Material Range: Compatible with aluminum alloys that require lightweight and corrosion-resistant properties

- Cost-Effective: Ideal for low-to-medium production volumes with low tooling costs

Aluminum Sand Casting in Innovaw

Innovaw has three sand casting production lines, including molding machine, sand fall machine, vibrating table, surface drying kiln, turning mold lifter, box closing machine, sand treatment equipment, storage and conveying system, sand Mixing and other equipment. Sand casting is available in resin, quartz sand and clay sand.

Our sand casting products cover industries such as marine vessels, automotive parts, aerospace, construction, heavy machinery, oil & gas, railroad industry, power generation facilities, and more. The product size ranges from 200*200mm to 1000*1000mm, the weight ranges from 100g to 100Kg, and the daily production capacity is 3-5 tons.

Products on Aluminum Sand Casting Lines

Material Scope

Innovaw's foundry complies with ASTM, JIS, DIN, ENAC, ISO, and GB material specifications. Common aluminum alloy grades suitable for sand casting processes are as follows:

- Aluminum Alloys

ASTM-A319, A413, A355, A356, A357

JIS-AC2B, AC4D, AC4C, AC3A, AC4A

DIN-AlSi7cu4, AlSi5cu1Mg, AlSi7Mg, AlSi12, AlSi9Mg, AlSi12Cu2Mg1, AlSi6Cu4

ENAC-45000, 45300, 42100, 44100, 43300

How Aluminum Sand Casting Works

Aluminum sand casting, as a metal thermoforming casting process, involves making a mold from sand and then pouring molten aluminum metal liquid into the sand mold to form an aluminum casting. Aluminum sand casting is a fundamental and adaptable process in metal fabrication that balances precision, flexibility and cost-effectiveness, and plays an important role especially in model pre-validation.

Why Innovaw Aluminium Sand Casting

Innovaw's primary mission is to meet customer expectations in quality, delivery, and performance. Our aluminum sand casting process exceeds our customers' expectations in terms of production capacity, technical support, quality control and service.

Production Capability

With complete productivity software and hardware and standardized plant, aluminum sand casting daily capacity of 3-5T.

With complete production management process, more than 20 production management experts and hundreds of workers provide professional production service for customers every day.

We provide one-stop service for the whole process from mold development to PPAP approval, from sand casting to surface treatment.

Technical Capability

More than 20 development engineers and more than ten die-casting industry experts provide full in-depth support to our customers.

Our team provides one-stop service from DFM analysis, 3D mold design, mold flow simulation analysis to rapid prototyping, from drawings to high quality products.

We are capable of providing valuable engineering solutions to help customers reduce manufacturing costs and improve product quality.

We have extensive experience in designing and producing products with complex geometries.

Quality Control

Our sand casting products take IATF 16949 quality management system as the implementation standard.

We utilize core tools such as APQP, FMEA, PPAP, MSA, SPC, etc. to achieve production process control.

Process audits are regularly conducted through VDA6.3 and product audits are regularly conducted through VDA6.5.

Regularly use 8D analysis and report to deal with customer complaints and solve problems from the root cause.

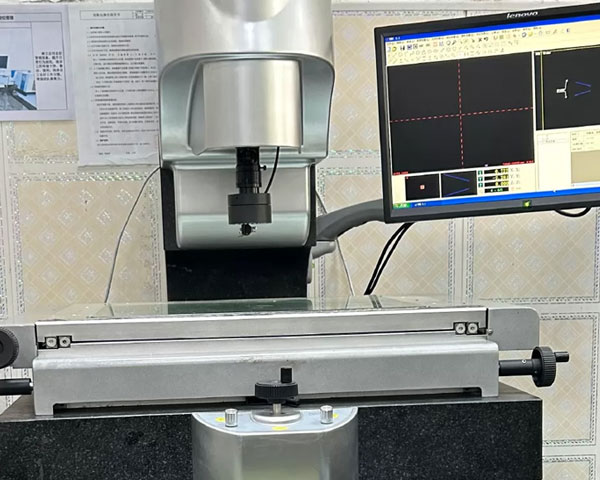

All products need to pass the whole process inspection, including Spectrometer, 3D scan, X-ray, ZEISS CMM, etc. from the first article to final inspection.

Aluminum Sand Casting FAQs

Q1. What metal materials can sand casting be applied to?

Sand casting can be applied to a wide range of metals, including iron, steel, aluminum, bronze, and brass.

Q2. Does sand casting deliver faster than other casting processes?

Sand casting often has shorter lead times for prototypes and large parts compared to processes requiring complex molds.

Q3. How do I know if my parts require sand casting?

Consider sand casting if your part is large, has simple to moderately complex geometry, or requires low-cost tooling.

Q4. In which industries is sand casting mainly used?

Sand casting is commonly used in automotive, construction, agriculture, and heavy machinery industries.

Q5. What is the difference between sand casting and high pressure die casting?

Sand casting uses expendable sand molds for versatile shapes, while high-pressure die casting produces precise, thin-walled parts at high speed.

Q6. Why Choose Aluminum Sand Casting for Your Products?

When choosing a manufacturing process, the most critical step is to understand the characteristics of the product itself. Aluminum sand casting offers unique advantages for specific applications.

1. When to Choose Sand Casting

- Complex structure: Products with internal cavities, curved structures or special-shaped contours

- Large size: Components with dimensions exceeding 1000mm in diameter

- Flexible surface treatment: When subsequent spraying, electroplating or oxidation treatment is required

- Small and medium-sized batch production: Without high mold investment, ideal for customized or small-scale orders

2. Key Advantages of Sand Casting

- Short production cycle and low cost: Particularly suitable for development stage or small batch orders

- Excellent material properties: Aluminum alloys offer good processability and thermal conductivity

- Strong adaptability: Can achieve complex structural designs difficult with other processes

- Cost-effective for large parts: More economical than other casting methods for sizable components

Aluminum sand casting is a manufacturing solution that takes into account cost, flexibility and performance. Whether in initial verification, trial production of samples, or in medium and low batch production scenarios, it can provide stable and reliable product quality and a shorter delivery cycle. Therefore, choosing sand casting is not only a consideration of process adaptability, but also an optimization of manufacturing efficiency and comprehensive cost.