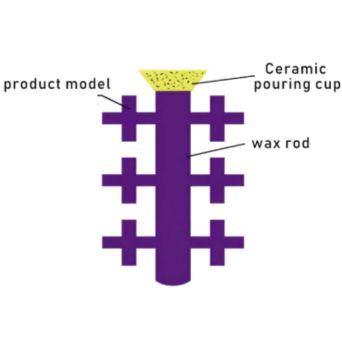

- Pattern Creation: A wax pattern is made using an injection mold. For small production runs, patterns can be handmade.

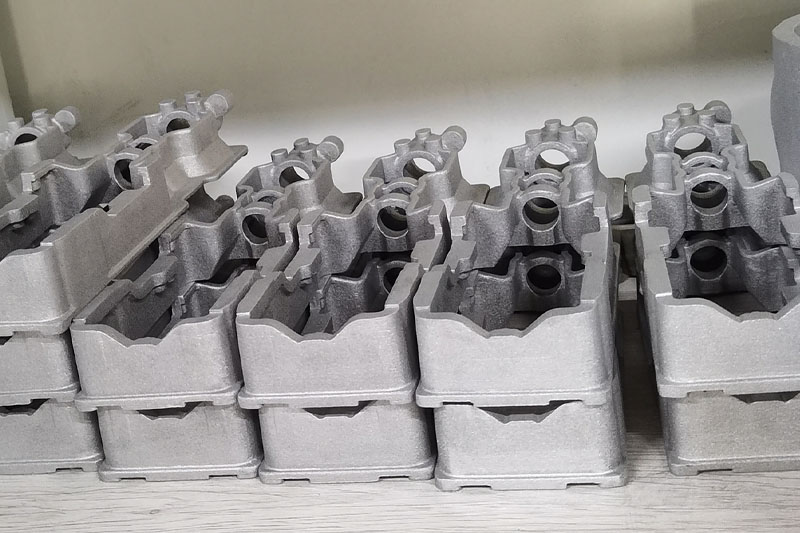

- Assembly: Multiple wax patterns are attached to a central wax sprue to form a "tree," optimizing the number of parts cast at once.

- Shell Building: The wax assembly is dipped repeatedly into ceramic slurry and coated with fine sand to create a hard shell. Each layer is dried before the next application, forming a durable mold.

- Wax Removal (Dewaxing): The mold is heated to melt and remove the wax, leaving a hollow ceramic shell.

- Preheating: The ceramic shell is heated to remove any remaining wax residue and prepare it for molten metal pouring.

- Casting: Molten metal is poured into the ceramic mold, filling the cavity left by the wax pattern.

- Cooling and Shell Removal: Once the metal solidifies, the ceramic mold is broken away using mechanical or chemical methods.

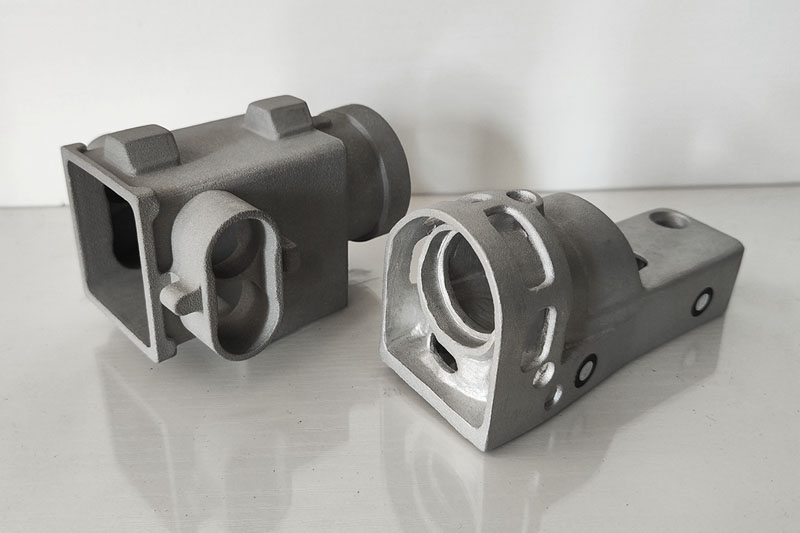

- Finishing: Excess material (like sprues) is removed, and secondary machining or polishing is performed if required.

Investment Casting

Aluminum investment casting, also known as lost-wax casting, is a precision manufacturing process used to create intricate metal parts with excellent dimensional accuracy and smooth surfaces. It involves creating a wax model (or pattern) of the part, surrounding it with a ceramic shell, and then melting away the wax to pour molten metal into the cavity left behind.

Features of aluminum investment casting:

- Precision: Offers exceptional dimensional accuracy and the ability to produce intricate details

- Material Versatility: Works with a wide range of metals, including aluminum, steel, titanium, and superalloys

- Surface Finish: Produces parts with a superior surface finish, often requiring minimal post-processing

- Near-Net Shape: Reduces the need for extensive machining or finishing

_1751361110_WNo_1000d700.jpg)

Aluminum Investment Casting in Innovaw

Innovaw has three production lines for investment casting, including injection wax machines, wax storage tanks, dewaxing kettles, mold conveying lines, dewaxing ovens, recycling devices, PLC control system and other complete sets of equipment, as well as auxiliary equipment such as sand mixer, sand fall machine, shot blasting machine, molding machine and pouring machine.

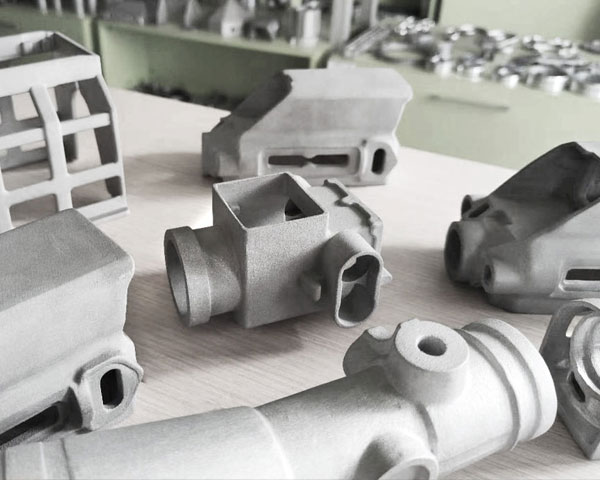

Our investment casting products cover architectural hardware, aerospace, automotive parts, hydraulic equipment parts, agricultural machinery parts, sanitary hardware, tools and so on. The size of the products is from 50*50mm to 400*400mm, the weight is from 5g to 5Kg, and the daily output is 3-5 tons.

Products on Aluminum Investment Casting Lines

Material Scope

Innovaw's foundry complies with ASTM, JIS, DIN, ENAC, ISO, and GB material specifications. Common aluminum alloy grades suitable for investment casting processes are as follows:

- Aluminum Alloys

ASTM-A319, A413, A355, A356, A357

JIS-AC2B, AC4D, AC4C, AC3A, AC4A

DIN-AlSi7cu4, AlSi5cu1Mg, AlSi7Mg, AlSi12, AlSi9Mg, AlSi12Cu2Mg1, AlSi6Cu4

ENAC-45000, 45300, 42100, 44100, 43300

How Aluminum Investment Casting Works

Aluminum investment casting relies on natural gravity (rather than high pressure) to make molten aluminum flow into the mold cavity, forming castings after cooling and solidifying. Unlike die casting, it does not require high pressure to push the metal flow, so the process is relatively gentle and suitable for some aluminum alloy parts that do not require high pressure injection.

Why Innovaw Aluminium Investment Casting

Innovaw's primary mission is to meet customer expectations regarding quality, delivery, and performance.

Production Capability

With complete productivity software and hardware and standardized plant, aluminum investment casting daily capacity of 3-5T.

With complete production management process, more than 20 production management experts and hundreds of workers provide professional production service for customers every day.

We provide one-stop service for the whole process from mold development to PPAP approval, from investment casting to surface treatment.

Technical Capability

More than 20 development engineers and more than ten die-casting industry experts provide full in-depth support to our customers.

Our team provides one-stop service from DFM analysis, 3D mold design, mold flow simulation analysis to rapid prototyping, from drawings to high quality products.

We are capable of providing valuable engineering solutions to help customers reduce manufacturing costs and improve product quality.

We have extensive experience in designing and producing products with complex geometries.

Quality Control

Our investment casting products take IATF 16949 quality management system as the implementation standard.

We utilize core tools such as APQP, FMEA, PPAP, MSA, SPC, etc. to achieve production process control.

Process audits are regularly conducted through VDA6.3 and product audits are regularly conducted through VDA6.5.

Regularly use 8D analysis and report to deal with customer complaints and solve problems from the root cause.

All products need to pass the whole process inspection, including Spectrometer, 3D scan, X-ray, ZEISS CMM, etc. from the first article to final inspection.

Aluminum Investment Casting FAQs

Q1. What metal materials can be used for investment casting?

Investment casting can be used for various metals, including steel, stainless steel, aluminum, titanium, and superalloys.

Q2. Does investment casting deliver faster than other casting processes?

No, investment casting typically has longer lead times than many other casting processes due to its intricate mold-making steps.

Q3. How do I know if my part needs investment casting?

Choose investment casting if your part requires high precision, complex geometries, or excellent surface finish with minimal machining.

Q4. In which industries is investment casting mainly used?

Investment casting is widely used in aerospace, medical, automotive, and defense industries for high-performance components.

Q5. What is the difference between investment casting and high pressure die casting?

Investment casting uses expendable ceramic molds for intricate shapes, while high-pressure die casting injects metal at high speed for mass production of simpler parts.

Q6. Why use aluminum investment casting to make your products?

Aluminum investment casting is a high-precision, high-quality casting process suitable for manufacturing aluminum alloy parts with complex shapes and high surface quality requirements. It is gradually becoming the first choice for many industries.

1. When to choose Investment Casting

- Complex structure and rich details: Such as internal cavities, thin walls, curved surfaces, undercut structures

- High requirements for dimensional accuracy and surface quality: Hope to reduce machining and improve part consistency

- Small batch production requirements: Small batch, high value-added products

- High-performance aluminum alloy materials: When shape is not suitable for die casting or gravity casting

- Industries with extreme quality requirements: Aerospace, automotive, medical, handicraft industries

2. Key advantages of Investment Casting

- Extremely high precision and complexity support: Can almost replicate the fine structure of the wax model 1:1, suitable for complex and precise parts

- Excellent surface quality and reduced post-processing: Smooth casting surfaces that often meet high appearance standards with minimal finishing

- High material utilization rate: Precision molding reduces blank size and redundant processing, minimizing material waste

- Suitable for high-performance aluminum alloys: Can use special aluminum alloys not suitable for other casting methods

- High design freedom: Enables realization of complex structural ideas not possible with traditional casting processes

If you need high-quality, high-precision, complex structured small batch aluminum alloy parts, then aluminum investment casting is undoubtedly a high-end manufacturing method worth considering. The precision, design freedom and material adaptability it brings will help your products improve in terms of performance, process and appearance, and win greater market competitiveness.