Agricultural Machinery Part Development

Project Description

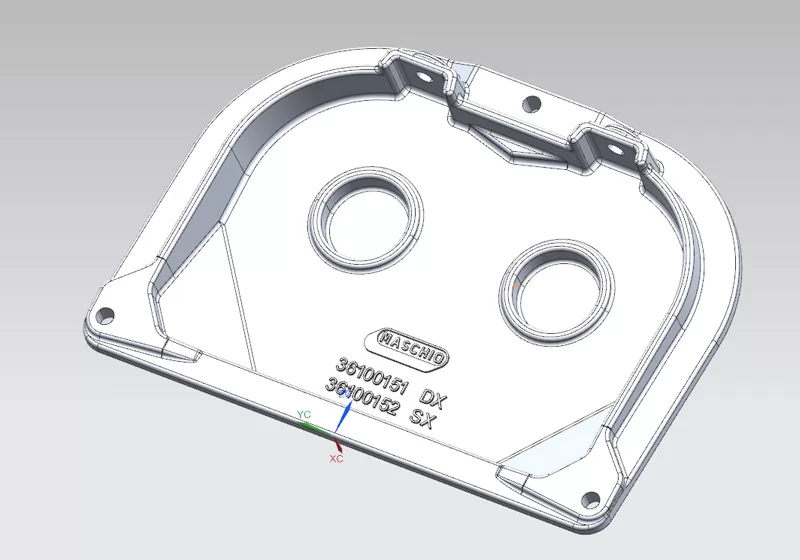

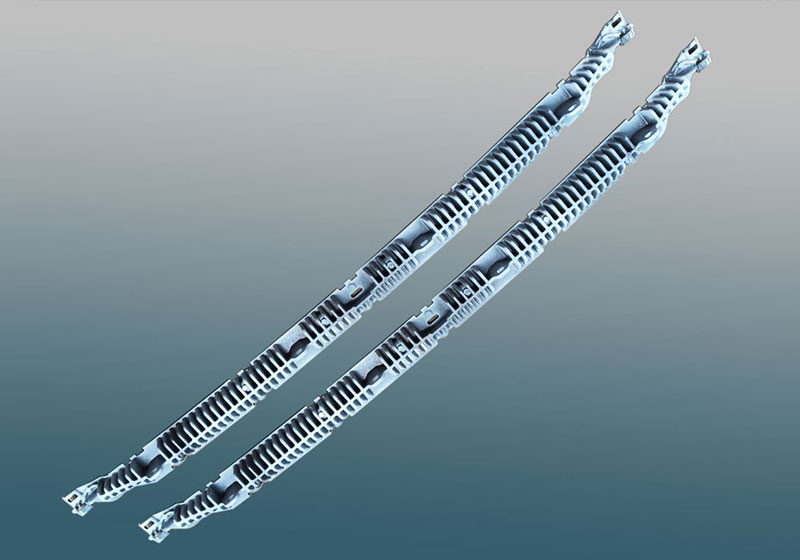

This is an agricultural machinery part, applied to equipment such as corn harvesters, tractors, and other agricultural machines, involving assembly and sealing functions.

1. Product Standards and Requirements:Material ADC12; dimensional tolerance grade ISO 2768-mk; flatness 0.5; minimum dimensional tolerance -0.05. No visible defects on appearance; surface roughness Ra6.3µm. PPAP approval must be completed and passed before mass production.

2. Product Challenges:Multi-surface irregular structure, upper and lower mold cores, prone to uneven clamping force, multiple assemblies required.

Risk Keywords:complex structure, high precision, sticking, porosity, assembly accuracy, zero surface defect

The overall project is of considerable difficulty, particularly testing our mold design capability and quality control capability.

Development Process

In accordance with the core methodology of APQP (Advanced Product Quality Planning) required by the international IATF 16949 standard, we formed a development team consisting of mold designers, casting engineers, machining engineers, measurement engineers, quality engineers, and sales staff to carry out comprehensive product development.

We first conducted DFM analysis of the product design. After communication with the customer, structural details were optimized under the premise of meeting functionality to improve manufacturability, and mutually agreed technical specifications and quality standards were established.

Considering the application environment and performance requirements of this agricultural machinery component, ADC12 was selected as the housing material. Based on the material properties and the core design elements of this product, and from the perspectives of technical feasibility, quality stability, and cost control, we finally determined the process route: high-pressure die casting + CNC precision machining, using a 500T high-pressure die casting machine.

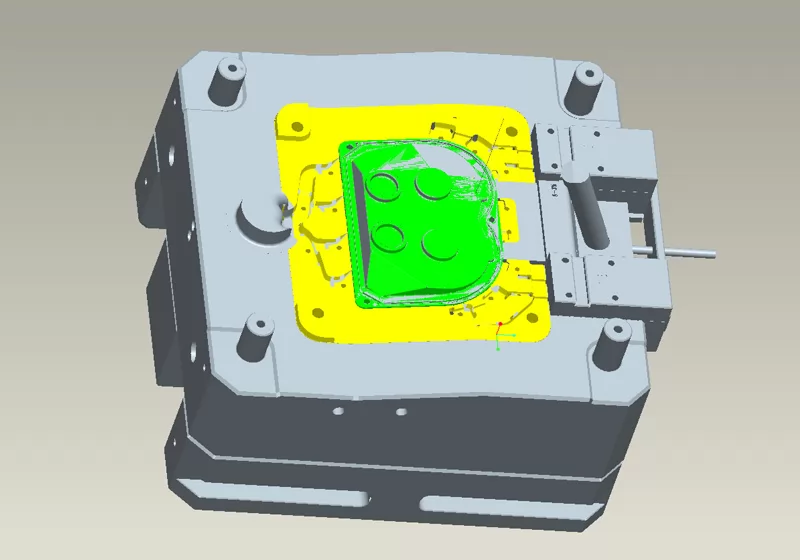

Subsequently, technical engineers carried out mold simulation and mold flow analysis to predict and optimize difficulties and process parameters, and established a preliminary process flow chart and process control plan.

Finally, during the subsequent practical procedures, the solution was gradually verified, and problems were identified and resolved.

Practical Verification and Optimization

For the development of this agricultural machinery component project, we adopted a method of first designing the overall process flow, then advancing verification step by step according to the process flow. From mold manufacturing, the project officially entered the actual manufacturing stage. We carried out work according to the initial process flow chart, while applying FMEA tools for risk analysis and evaluation of various potential failure modes, and applied SPC (Statistical Process Control) to key parameter data, analyzing with SPC tools for continuous monitoring and improvement. During the entire manufacturing process, the main key issues encountered were as follows:

A. Structural Adjustment to Solve Sticking Problem

During the mold trial stage, there was widespread sticking feedback on site, with a defect rate of more than 70%. After technical investigation and review, the project development team confirmed the causes: the product had a multi-surface irregular structure with multiple steps and concave-convex transitions; the mold core design lacked sufficient symmetry; and the draft angle was unreasonable, leading to uneven clamping force between upper and lower mold cores. Solution:

1. Adjust mold structure and add undercut design to facilitate demolding.

2. Modify draft angles to make demolding conditions of upper and lower mold cores consistent.

After optimization, further mold trials and subsequent sample production demonstrated that the sticking problem was completely solved.

B. Dedicated Fixture to Optimize Assembly Difficulty

This agricultural machinery part casting required multiple assemblies, especially two sealing rings. Traditional manual assembly was inefficient and had quality issues. After team discussions, a dedicated fixture was designed specifically for this purpose, which greatly improved assembly efficiency and ensured assembly quality.

C. Other Minor Issues Encountered

During actual sample trials, the following issues were also found:

1. Surface peeling problem

2. Surface contamination problem

3. Surface carbonization problem

4. Pin protrusion problem

5. Large hole step protrusion problem

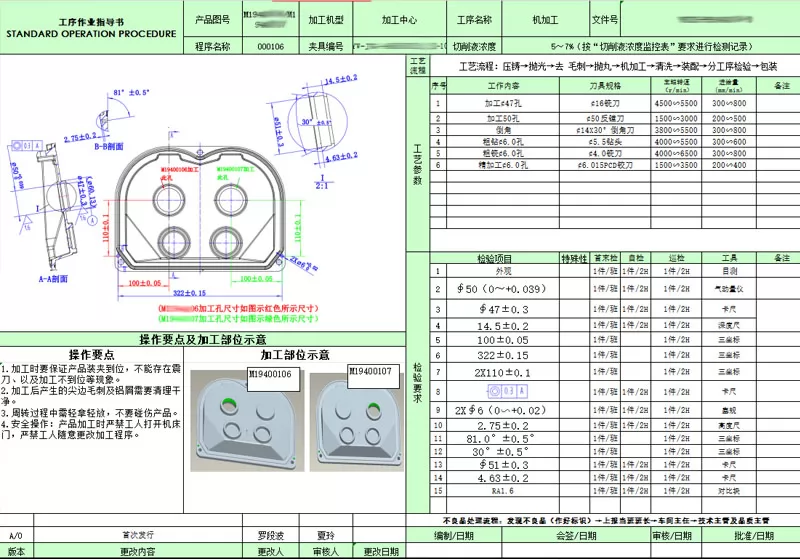

For the above quality issues, the team leveraged its rich aluminum die casting development experience, solving them one by one through mold modification, die casting parameter adjustments, surface coating, machining, etc. These issues, their causes, solutions, and results were documented in SPC, FMEA, process control plans, and work instructions to ensure such problems would not recur.

Quality Control

The entire development process was a systematic process of identifying and controlling quality risks and continuously optimizing processes. The agricultural machinery component project team, with its rich experience and solid technical expertise, carried out technical reviews and repeated verification at every process stage, systematically identifying and overcoming potential risks, and established detailed work instructions for each process.

Quality engineers strictly followed the IATF 16949 quality system and implemented the full APQP process requirements to achieve complete quality control. During the process, FMEA, SPC, MSA, and process control plans were established and executed to prevent potential process risks and quality risks, and to control quality variation. Finally, PPAP documents were completed and approved by the customer, laying a solid foundation for mass production.

Results and Evaluation

Final Product Indicators:

1. Dimensional accuracy: all compliant with ISO 2768-mk requirements.

2. Surface quality: no visible defects, compliant.

3. Assembly quality: customer satisfaction achieved.

5. PPAP completed and approved by customer.

The development of this agricultural machinery component aluminum casting by Innovaw, with its high technical difficulty and strict comprehensive performance requirements, served as a test of the manufacturer’s overall capability. Through our solid expertise in high-pressure die casting, precision CNC machining, and consistent quality management system, we successfully overcame challenges and delivered a high-quality product that met and even exceeded customer expectations.

This fully demonstrated our casting development team’s professional capability in systematic problem analysis and rapid closed-loop improvement for complex structural parts.

Production Process

Mould making→Melting→High Pressure Die Casting→Cutting the sprue and riser→Polishing→Deburring→Shot Blasting→Machining→Cleaning→Assembly→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.