8D-Report

The 8D Report (Eight Disciplines Report) is a structured problem-solving methodology originally developed by Ford Motor Company and now widely adopted across industries including automotive, aerospace, and manufacturing. It systematically analyzes and resolves quality issues through eight steps: team formation, problem description, temporary containment, root cause analysis, permanent corrective action, verification and implementation, prevention of recurrence, and team recognition.

The 8D Report is primarily used to address major quality issues, customer complaints, or recurring defects. Its core significance lies in:

Rapidly controlling problems to prevent further customer impact;

Thoroughly investigating root causes to ensure issues are genuinely resolved;

Establishing preventive mechanisms to stop similar problems from recurring;

Enhancing customer trust by demonstrating supplier professionalism and accountability.

As a company that manufactures metal components for global clients, we employ the 8D report as a core quality management tool. Upon receiving customer feedback or identifying internal anomalies, we immediately initiate the 8D process:

Forming cross-functional teams to ensure comprehensive issue resolution;

Rapidly implementing containment measures to safeguard customer production;

Conducting systematic analysis to identify root causes and develop effective permanent corrective actions;

Finally, we transform these lessons into standardized procedures for future production.

Through the 8D report methodology, we not only resolve issues efficiently and guarantee delivery quality but also continuously enhance our core competitiveness through ongoing improvement, delivering more reliable products and services to our global customers.

Sample Quality Documents

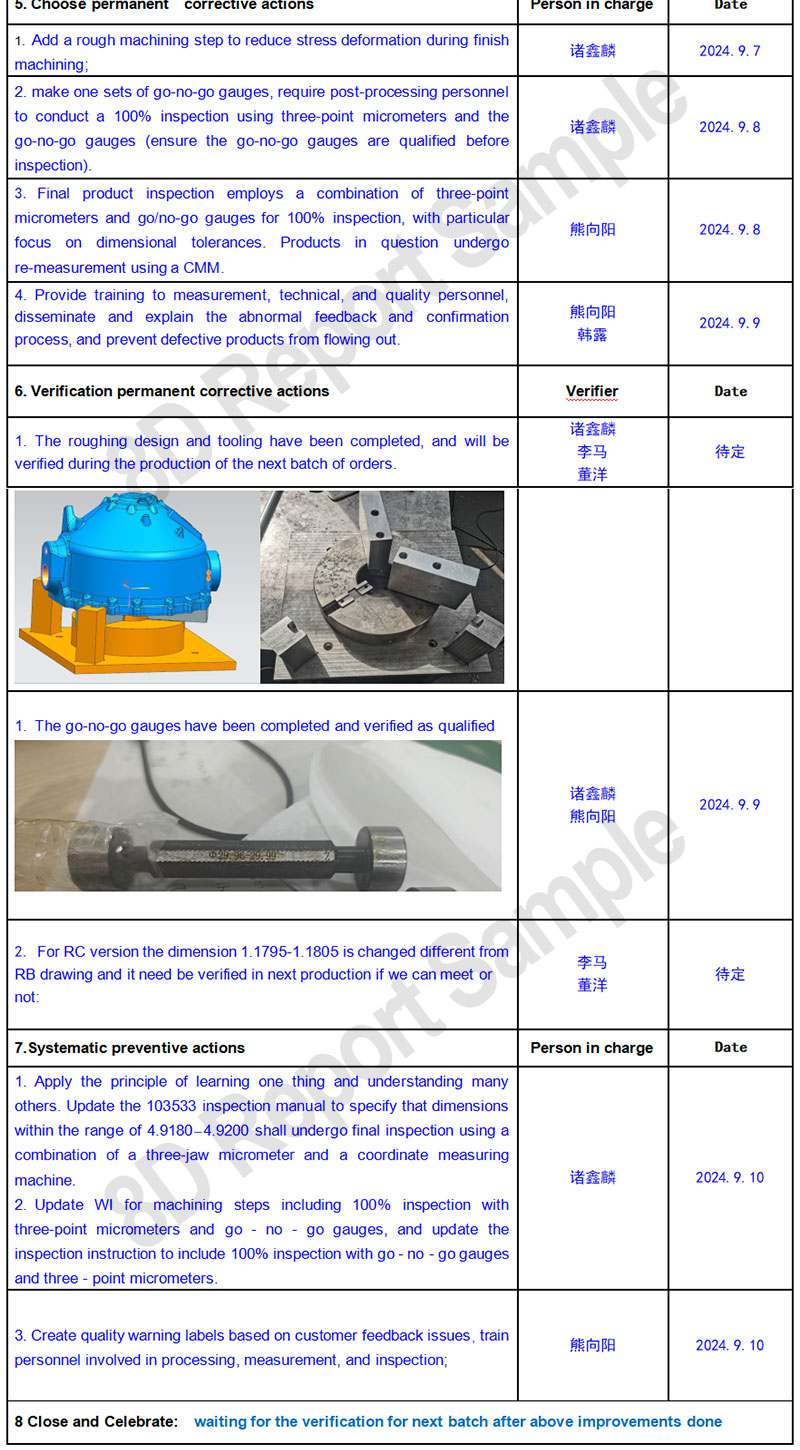

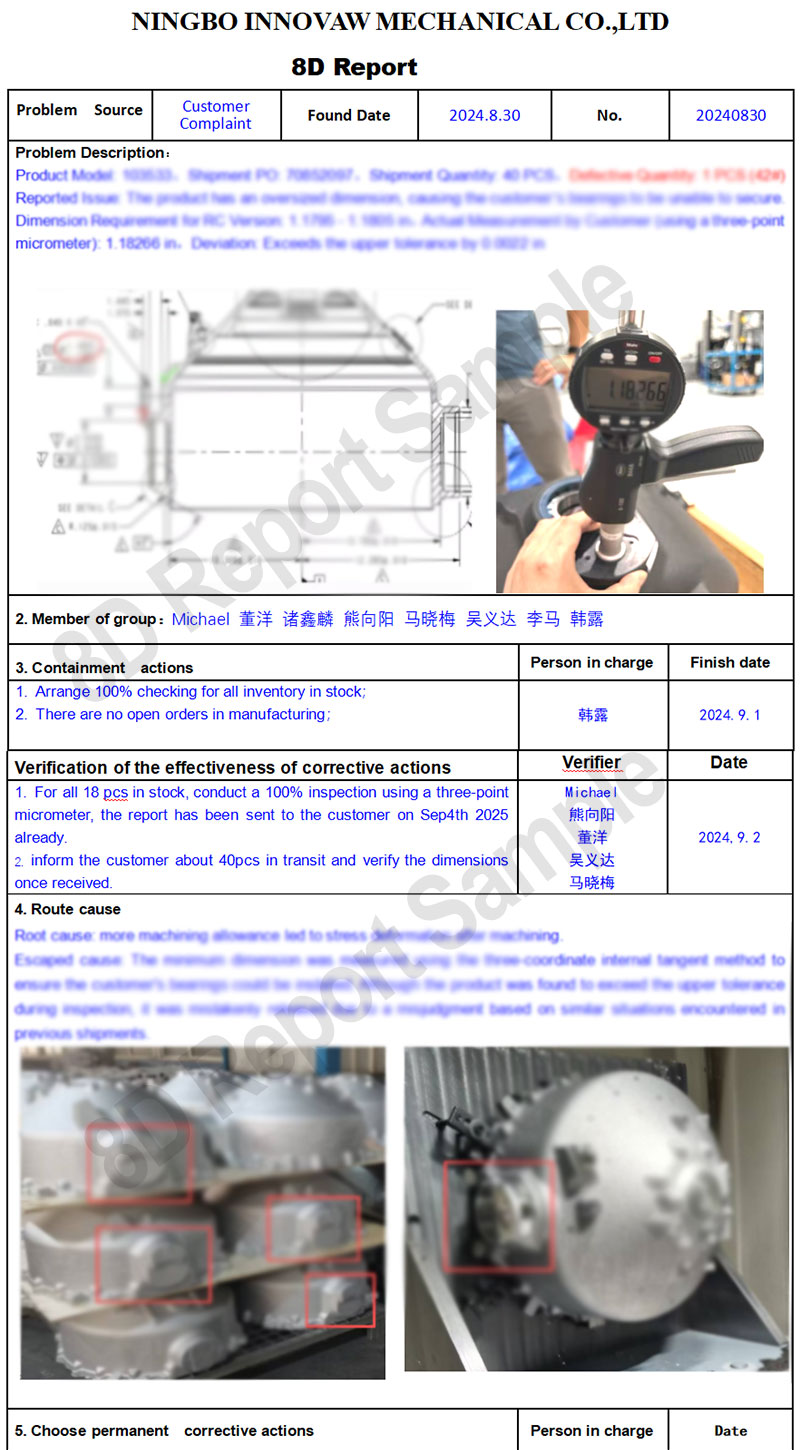

Section 1 of the 8D Report