Product Description

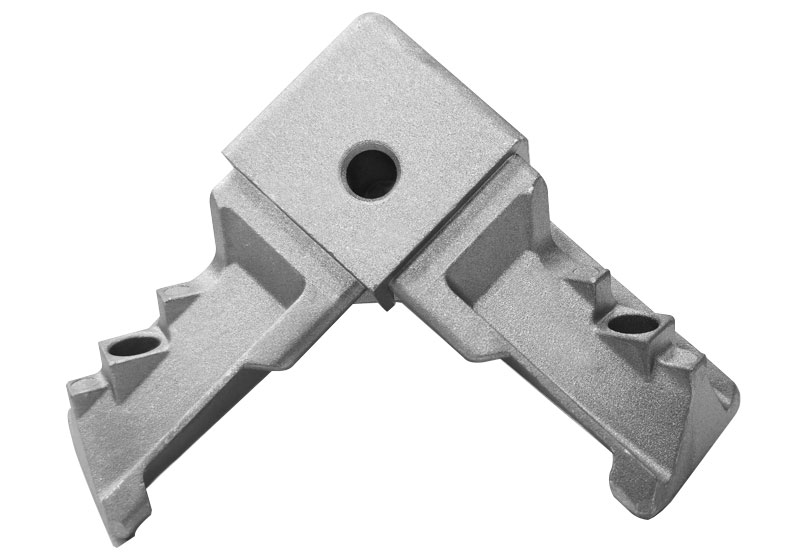

This is a zinc alloy corner connector, a component of architectural door and window systems. This cast corner connector is used in building door and window connection systems, serving as a critical structural connector for architectural doors and windows.

Its primary functions include:

1. Enabling three-way (90°) connections in door and window systems, ensuring the overall frame structure forms a rigid unit to prevent loosening or misalignment.

2. Transmitting assembly forces between different structural components, allowing smooth integration of varied materials or shapes within the system.

3. Supporting pulley or hinge systems to bear the weight of door/window sashes, ensuring smooth operation without sagging.

4. Maintains structural stability.

This zinc alloy corner connector casting not only possesses outstanding mechanical strength and precision but also offers excellent corrosion resistance, lightweight properties, superior protective performance, and convenient installation/maintenance. The finished product fully meets customer design objectives, providing a higher-performance, more reliable solution for this type of building equipment design.

This zinc alloy corner connector casting adopts the zinc high-pressure die casting one-piece molding process, and the surface adopts the vibration grinding process, which has the characteristics of high precision, small tolerance, small wall thickness, high production efficiency, low material loss, light weight but high strength, which is a perfect fit for the mass production needs of this door and window accessory.

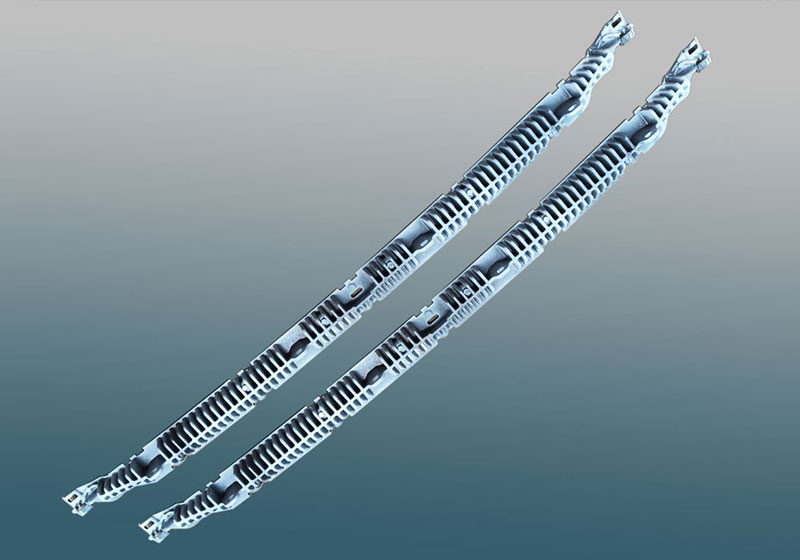

Production Process

Mould making→Pressure Die Casting→Cutting the sprue and riser→Grinding→Vibratory Finishing-→Packaging & inspection

Production Video

Product story

As a key component used in building door and window systems, door and window fittings are required to have the following key characteristics.

high strength and hardness, good wear resistance, excellent dimensional stability, good corrosion resistance, assembly friendliness and other characteristics to adapt to different working environments. This was the basis for the customer's requirements for the zinc alloy casting of this connecting bracket casting.

As a long-standing customer who has cooperated with Innovaw for many years, the customer has full trust in Innovaw. After receiving the customer's requirements and drawings, we first conducted a DFM analysis of the product design to ensure that the product design meets the functional requirements, while reducing costs, improving productivity and minimizing defects during the manufacturing process.

During the analysis process, INNOVAW's professional engineers analyzed the product design in all aspects, from mold layout, extraction angle, part marking, etc., and put forward reasonable opinions and solutions from the production point of view, and finally the customer accepted our opinions and improved them, so that the final product was produced and delivered smoothly.

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.

Share your thoughts

Showing

6

of

0

reviews