Top 10 Zinc Pressure Die Casting Manufacturers and Suppliers in the World

Who are the best zinc pressure die casting manufacturers in the world? The global zinc pressure die casting industry is driven by companies with strong engineering.

From idea to final product, we transform raw metal into tangible solutions. With 20+ years of expertise, we've served 200+ clients and delivered 3,000+ successful cases across: Automotive components, Aerospace, marine vessels, Lighting fixtures, medical devices, Energy, telecommunications, instrumentation, etc.

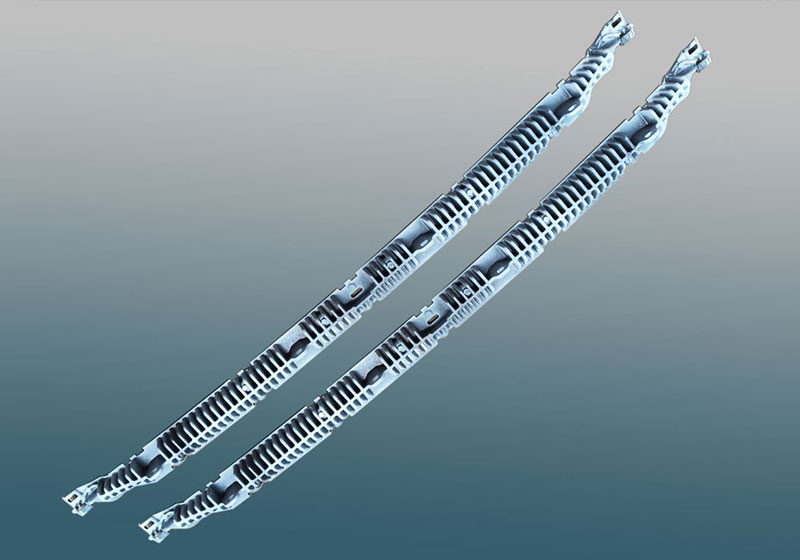

This is a custom-designed motor stator tube casting. The product features a hollow cylindrical structure with double-layer concentric coaxial sleeves, presenting complex internal and external geometries.

This is a customized large aluminum alloy casting, which is presumed to be used in the structural housing of dynamic balance system on ships and yachts, or power transmission housing such as gearbox. This aluminum casting is made by aluminum low pressure die casting and cnc machining process.

This is a custom-designed LED work light housing for heavy-duty equipment, such as trucks and bulldozers. The LED housing not only protects the internal LED components but also serves multiple functions including thermal management and mechanical support.

This is a customized water heater parts aluminum castings, the material is aluminum alloy, presumably for the water heater circulating pump motor end cover. This water heater fittings aluminum castings using aluminum high-pressure die-casting one-piece molding and cnc machining process, the finished product not only has excellent mechanical properties and good machining accuracy, but also has good thermal conductivity, corrosion resistance, lightweight, good protection features, but also easy to install and maintain.

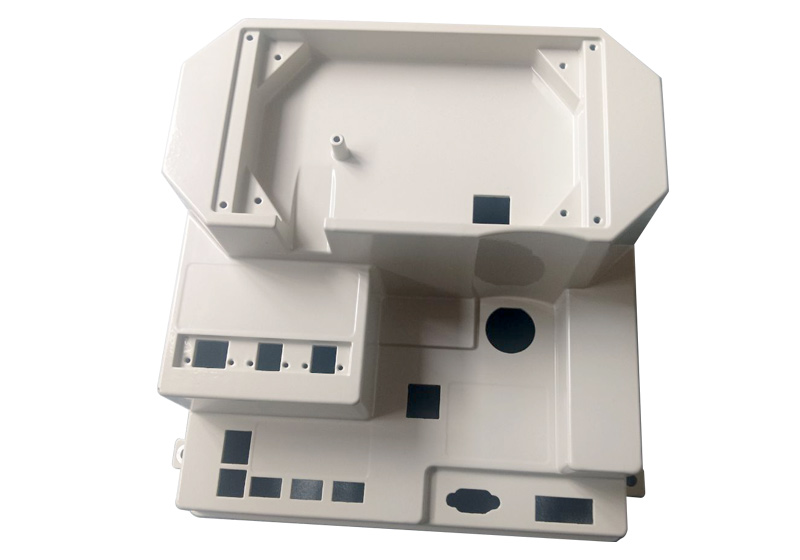

This is a customized enclosure for a power integration module, serving as a casting shell in the power system to carry and protect the core electrical components inside the control unit.

This automotive LED headlight heat sink casting is customized for heavy trucks and has the functions of supporting the housing and dissipating heat.

Innovaw is a professional manufacturer of aluminum castings and machined parts. It has been serving global customers for more than 20 years and has won good reputation among customers.

We provide customers with solutions in aluminum-zinc high pressure die casting, aluminum low pressure casting, aluminum gravity casting, aluminum investment casting, aluminum sand casting, CNC precision machining, etc.

At Innovaw, a significant proportion of our team consists of excellent Development Engineers, Quality Engineers, and Industry Experts. We value every product collaboration opportunity and are committed to delivering perfect products to our customers through a relentless pursuit of excellence.

Innovaw is a company that can turn customers' ideas and drawings into real mass-produced products. We are a customer-focused company with deep roots in product development, process control, quality control, and professional services to realize systematic development and production.

Over 20 years of casting and machining experience; IATF 16949 certified; First-pass yield >99%; Customer complaint rate ≤600 PPM; On-time delivery rate 98%.

Experience in developing over 3,000 different products; Strong development capability with PPAP approval rate ≥95%; 80% of business from long-term partners.

ERP system, automation production, MES Management; Comprehensive technical support including DFM and mold flow analysis; Mastery and integration of multiple casting technologies; Full-spectrum testing capabilities with 100% coverage.

Customized production from 1 to 1 million units; Flexible pricing with quality as a priority; Flexible shipping to ensure customers' safety stock; Fast response to design changes.

24-hour after-sales response; 8D Report Completion Rate: 100%; closed-loop customer feedback system; compliance with regulations, contracts, and business ethics.

ISO 14001 Environmental Management Certification and Government Green Factory Recognition; ISO 45001 Certification ensuring employee health and safety; SA8000 Certification safeguarding workers' rights.

Empowering you to fully understand everything about us-start exploring now

We are an aluminum casting manufacturer with 20 years of experience. Depending on the casting process, Innovaw group own several foundry and machining facility divisions to provide customers with solutions for aluminum and zinc high pressure casting, aluminum low pressure casting, aluminum gravity casting, aluminum investment casting, aluminum sand casting and CNC precision machining. we provide one-stop service from drawings to high quality products.

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Generally, we will respond within one to three business days. If the product is complex, we may require additional time to analyze the manufacturing process and costs, and we will communicate with you accordingly.

Our delivery terms include FOB, CIF, EXW, CFR, DDU, etc.

Speak to one of our experts today to learn more about our products

Learn About Our Company News and Useful Casting Knowlege

Who are the best zinc pressure die casting manufacturers in the world? The global zinc pressure die casting industry is driven by companies with strong engineering.

The product had already completed the design and process engineering phases and was currently undergoing review for the Production Part Approval Process (PPAP).

Looking for reliable aluminum pressure die casting manufacturers? Wondering which suppliers offer the best precision, quality, and production capabilities?